Ga40Sb60/Sb superlattice phase transition film material for high-speed low-power-consumption phase change memory, and preparing method thereof

A phase-change memory and thin-film material technology, applied in the field of microelectronics, can solve problems such as unsatisfactory data retention, and achieve the effects of small changes in the overall structure, improved stability and reliability, and accelerated phase transition speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

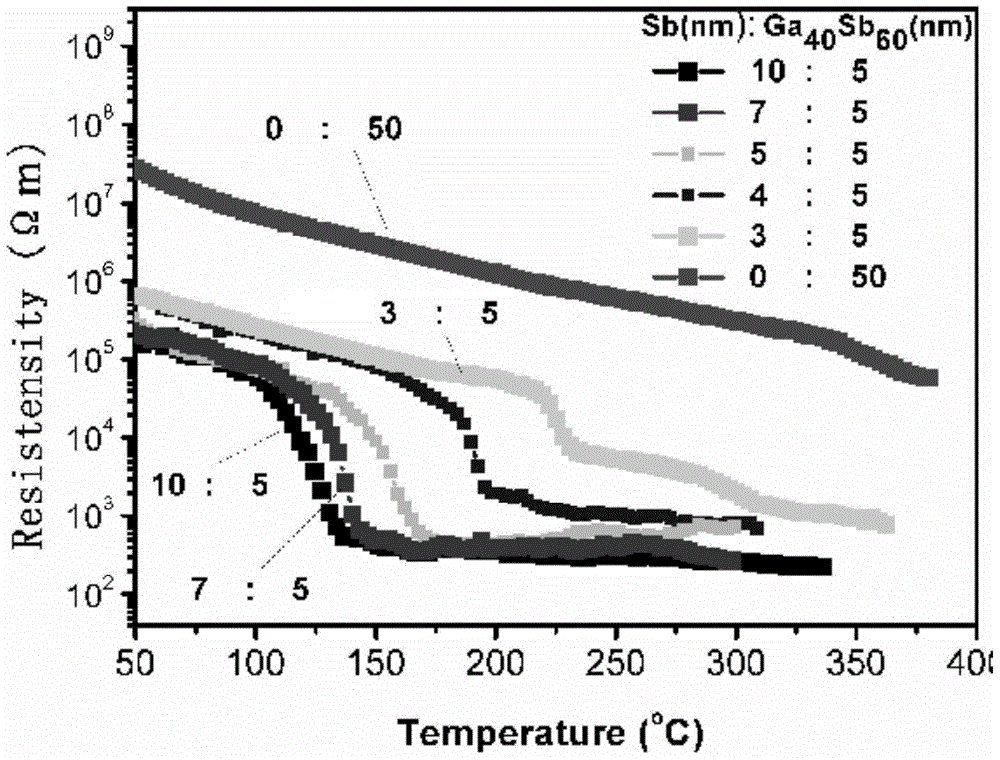

[0027] Ga 40 Sb 60 / Sb superlattice phase change film material is a multilayer composite film structure with a thickness of 6-80nm; made of Ga 40 Sb 60 Layers and Sb layers are alternately deposited and compounded, that is, in thin films, according to Ga 40 Sb 60 Layer - Sb Layer - Ga 40 Sb 60 The sequence of layer-Sb layer... is repeated alternately.

[0028] A layer of Ga 40 Sb 60 layer and a layer of Sb as an alternating period, the latter alternating period of Ga 40 Sb 60 layer deposited on top of the Sb layer of the previous alternate period. Ga 40 Sb 60 The layer contains two elements, Ga and Sb, and the atomic ratio of Ga and Sb is 4:6.

[0029] The above Ga 40 Sb 60 The general formula [Ga 40 Sb 60 (a) / Sb(b)] x Indicates that a is a monolayer Ga 40 Sb 60 The thickness of the layer, 1nm≤a≤50nm; b is the thickness of the single-layer Sb layer, 1nm≤b≤50nm; x is Ga 40 Sb 60 layer and the number of alternating periods of the Sb layer, or a layer of Ga...

Embodiment 2)

[0043] Ga 40 Sb 60 The film structure of the Sb-like superlattice phase change film material is [Ga 40 Sb 60 (5nm) / Sb(7nm)] 4 , that is, each layer of Ga 40 Sb 60 The thickness of the layer is 5nm, the thickness of each layer of Sb is 7nm, Ga 40 Sb 60 layer and Sb layer alternate period number is 4, Ga 40 Sb 60 The thickness of the / Sb-type superlattice phase-change thin film material is 48nm.

[0044] The rest of the preparation method are the same as in Example 1, the difference is: step 3. magnetron sputtering prepares Ga 40 Sb 60 / Sb superlattice phase change thin film material, the sputtering time of each layer of Sb is 21s.

Embodiment 3)

[0046] Ga 40 Sb 60 The film structure of the Sb-like superlattice phase change film material is [Ga 40 Sb 60 (5nm) / Sb(5nm)] 5 , that is, each layer of Ga 40 Sb 60 The thickness of the layer is 5nm, the thickness of each layer of Sb is 5nm, Ga 40 Sb 60 layer and Sb layer alternate period number is 5, Ga 40 Sb 60 The thickness of the / Sb superlattice phase change film material is 50nm.

[0047] The rest of the preparation method are the same as in Example 1, the difference is: step 3. magnetron sputtering prepares Ga 40 Sb 60 / Sb superlattice phase change thin film material, the sputtering time of each layer of Sb layer is 15s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com