Bean yoghourt fermenting agent with processing suitability as well as preparation method and application thereof

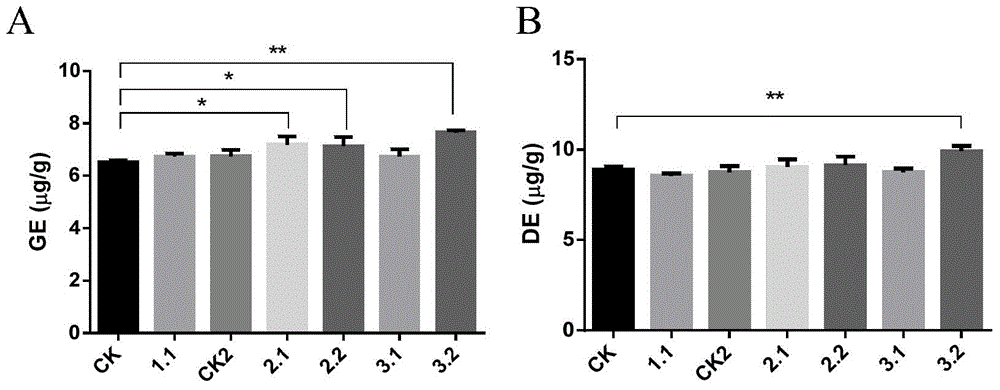

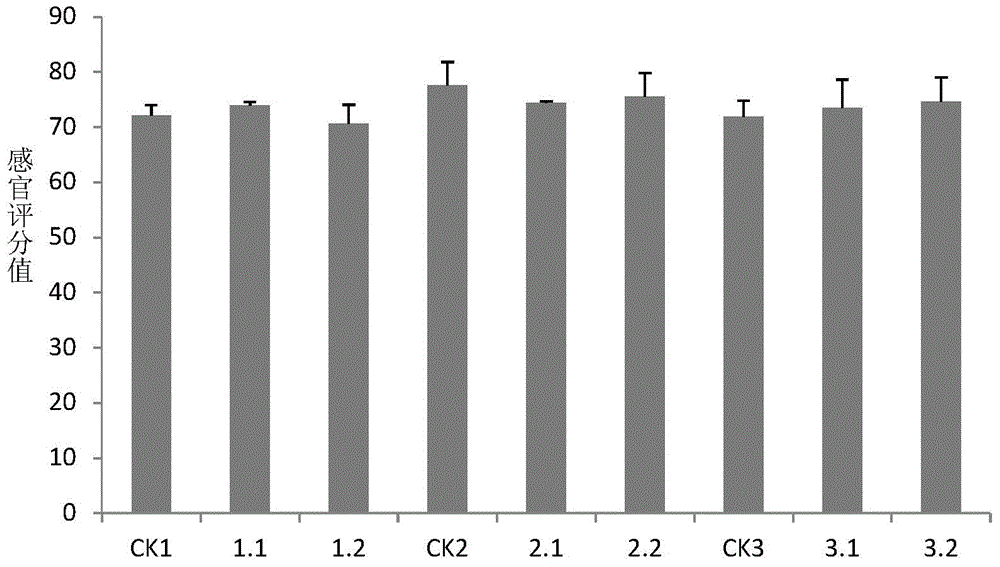

A technology of milk adaptability and starter, applied in the field of bioengineering, can solve the problems of less than 10% of the proportion, weak conversion ability of soybean isoflavones, low bioavailability of soybean isoflavones, etc., and achieve improved protein digestibility , Improve the biotransformation rate, increase the content of genistein and daidzein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: One of the transformation of kefir grain

[0036] (1) Kefir strains: Kefir No. 1 (Turkish strain), Kefir No. 2 (Caucasus strain), and Kefir No. 3 (Tibet strain).

[0037] (2) Exogenous strains: including Bifidobacterium infantis, Lactobacillus plantarum, Bifidobacterium bifidum, Bifidobacterium animalis, Lactobacillus helveticus ), Lactobacillus fermentium, Enterococcus faecalis, etc.

[0038] (3) Activation of strains: Dissolve whole milk powder in sterile water, dilute to 150mL to make reconstituted milk with a mass volume percentage of 10% (w / v), pasteurize (85°C, 10min) and cool to room temperature , inoculate kefir (kefir) grains, inoculum size 3.3% (5 / 150, v / v), ferment at 25°C for 24 hours, then filter out kefir grains and re-inoculate into freshly prepared reconstituted milk, and activate repeatedly for 3 days 3 Second-rate.

[0039] (4) Kefir granule phase transformation: prepare 10% (w / v) reconstituted milk by the method of step (3), inoculate...

Embodiment 2

[0040] Embodiment 2: the transformation two of kefir grains

[0041] The kefir grains obtained after the last milk change of the exogenous flora transformation obtained in Example 1 are filtered out, mixed with freshly cultivated Lactobacillus helveticus, Bifidobacterium bifidum, and Bifidobacterium infantis to inoculate to 10% In the reconstituted milk, the inoculation amount of each bacteria was 10 6 CFU / mL, fermented at 25°C for 24 hours; in this way, the kefir grains were filtered out on the 12th day, and the filtrate was vacuum freeze-dried, and the obtained bacterial powder was the fermentation agent at the end of the transformation; the kefir grains were continued to be cultured with milk, However, the exogenous flora was no longer added, and the milk was changed 10 times for 10 days. On the 22nd day, kefir grains were filtered out, and the filtrate was vacuum freeze-dried. The obtained bacterial powder was the starter in the stable period.

Embodiment 3

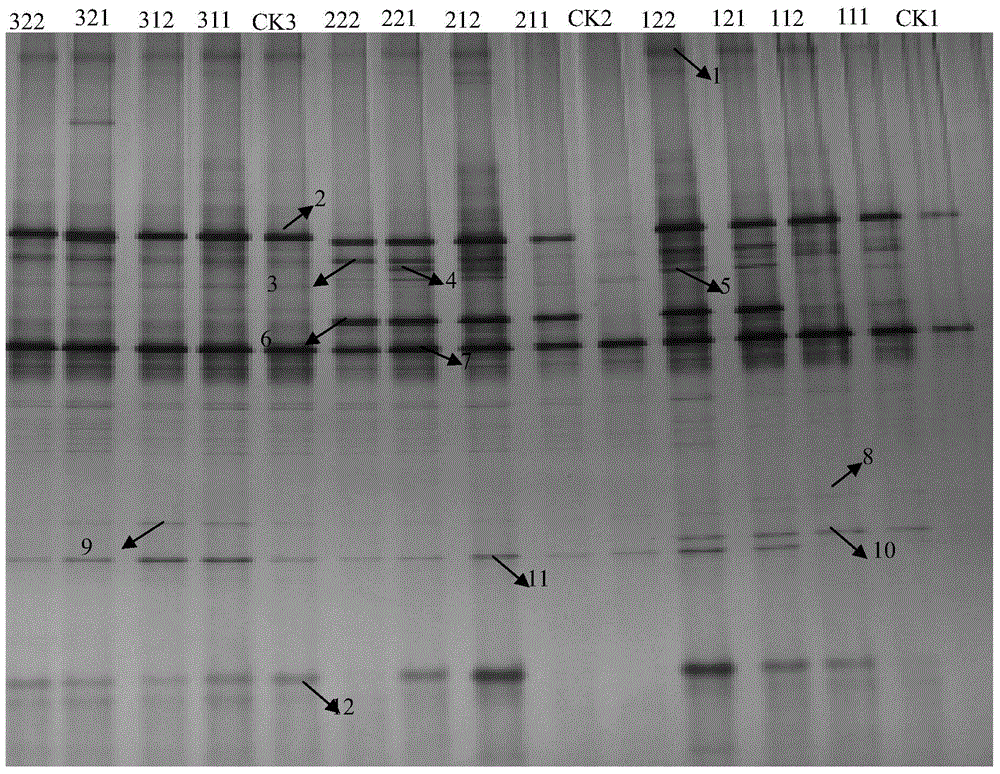

[0042] Embodiment 3: the DGGE analysis of kefir bacterial phase

[0043] 1) DNA extraction of freeze-dried powder flora: take 0.13g freeze-dried powder, add 500ul TES buffer (containing 50mg / m1 lysozyme), shake fully with a vortex shaker for 10 minutes, suspend the precipitate, keep warm at 37°C for 1h, add 150ul 20% SDS (W / V) was incubated at 37°C for 30min, added 300ul 5M NaCl to mix, centrifuged at 2000xg for 15min, took the supernatant, added an equal volume of phenol:chloroform:isoamyl alcohol (25:24:1) to mix Uniformly, centrifuged at 12000×g for 20min, took the supernatant, extracted repeatedly 2 times, took the supernatant, added 10% NaAC (pH5.4) and isopropanol of equal volume to the supernatant, mixed well, placed in the refrigerator for 30min, Centrifuge at 12000xg for 15min, discard the supernatant, wash the precipitate with 70% ethanol, centrifuge at 12000xg for 15min, take the precipitate, dry it, add 30ul ddH 2 DNA was dissolved in O, detected by 0.5% agarose g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com