Preparation method of chitosan quaternary ammonium salt hyaluronic acid nanogel coated with basic fibroblast growth factors

A chitosan quaternary ammonium salt and fibroblast technology, which is applied in the field of pharmacy, can solve the problems of easy degradation and inactivation, limited therapeutic effect, etc., and achieves simple preparation technology, high encapsulation capacity, and good mucoadhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

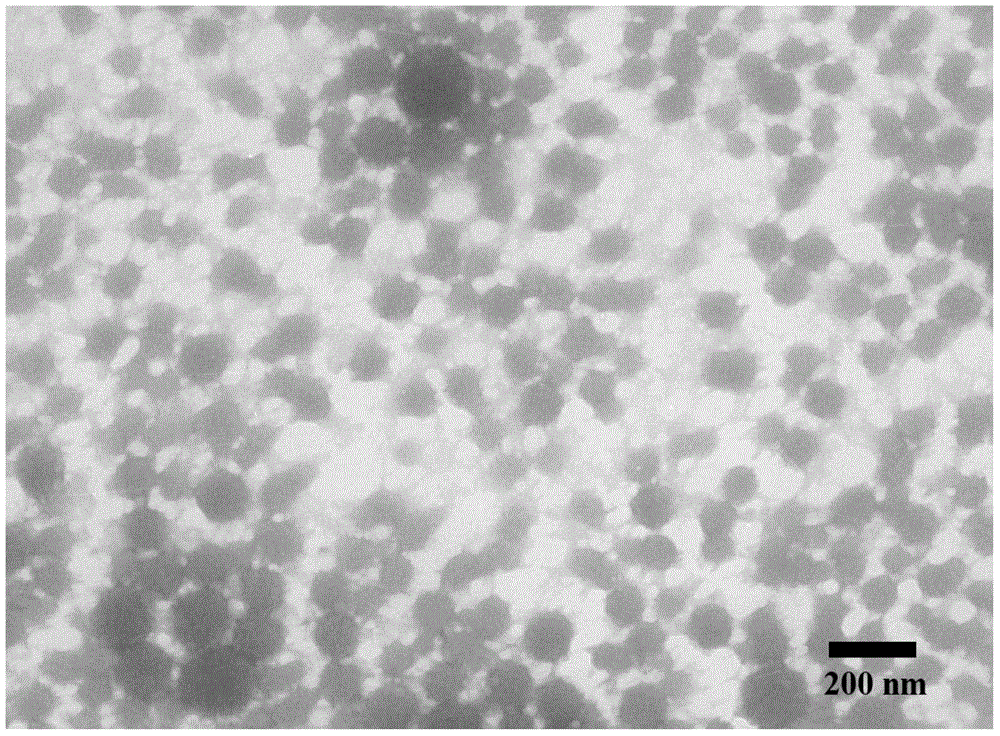

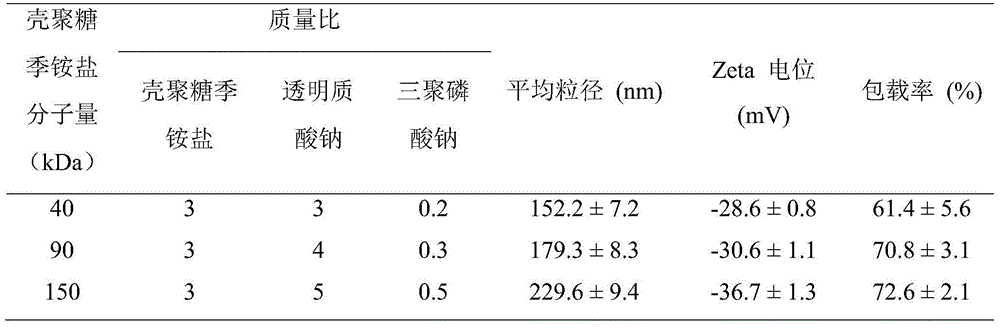

Embodiment 1

[0024] Take 30 mg of chitosan quaternary ammonium salt with a molecular weight of 40 kDa, dissolve it in 10 mL of deionized water, add 10 mL of 2 mg / mL basic fibroblast growth factor solution dropwise under stirring, and 1 mL of 0.2% (w / v) tripolyphosphoric acid Sodium solution, drop in 20 minutes, stir at 200 rpm at room temperature for 30 minutes, add 10 mL of sodium hyaluronate solution containing 0.3% (w / v) dropwise under stirring conditions, drop in 30 minutes, adjust with sodium hydroxide pH to pH 4.0, stirred at room temperature, stirred at 200 rpm for 5 hours, centrifuged at 15,000 rpm for 2 hours, removed the supernatant, and freeze-dried to obtain the chitosan quaternary ammonium hyaluronic acid loaded with basic fibroblast growth factor acid nanogel.

Embodiment 2

[0026] Take 30 mg of chitosan quaternary ammonium salt with a molecular weight of 90 kDa, dissolve it in 10 mL of deionized water, add 10 mL of 2 mg / mL basic fibroblast growth factor solution dropwise under stirring, and 1 mL of 0.3% (w / v) tripolyphosphoric acid Sodium solution, drop in 20 minutes, stir at 200 rpm at room temperature for 30 minutes, add 10 mL of sodium hyaluronate solution containing 0.4% (w / v) dropwise under stirring conditions, drop in 30 minutes, adjust with sodium hydroxide pH to pH 5.0, stirred at room temperature, stirred at 200 rpm for 5 hours, centrifuged at 15,000 rpm for 2 hours, removed the supernatant, and freeze-dried to obtain the chitosan quaternary ammonium hyaluronic acid loaded with basic fibroblast growth factor acid nanogel.

Embodiment 3

[0028] Take 30 mg of chitosan quaternary ammonium salt with a molecular weight of 150 kDa, dissolve it in 10 mL of deionized water, add 10 mL of 2 mg / mL basic fibroblast growth factor solution dropwise under stirring, and 1 mL of 0.5% (w / v) tripolyphosphoric acid Sodium solution, drop in 20 minutes, stir at 200 rpm at room temperature for 30 minutes, add 10 mL of sodium hyaluronate solution containing 0.5% (w / v) dropwise under stirring conditions, drop in 30 minutes, adjust with sodium hydroxide pH to pH 6.0, stirred at room temperature, stirred at 200 rpm for 5 hours, centrifuged at 15000 rpm for 2 hours, removed the supernatant, and freeze-dried to obtain the chitosan quaternary ammonium hyaluronic acid loaded with basic fibroblast growth factor acid nanogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com