Silicon carbide fiber lightweight high-temperature insulating material, and preparation method thereof

A technology of silicon carbide fiber and thermal insulation material, which is applied in the thermal protection of high-temperature equipment or devices, silicon carbide fiber lightweight high-temperature thermal insulation material and the field of preparation thereof, can solve the problem of poor thermal insulation performance, poor mechanical performance and thermal insulation performance. limited and other problems, to achieve the effect of good thermal insulation performance, low total thermal conductivity, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Mix 100g of chopped silicon carbide fibers with 500g of absolute ethanol, add 20g of polymethylsilsesquioxane, transfer to a mixer, and stir vigorously for 20 minutes to mix evenly to obtain ceramic fiber slurry;

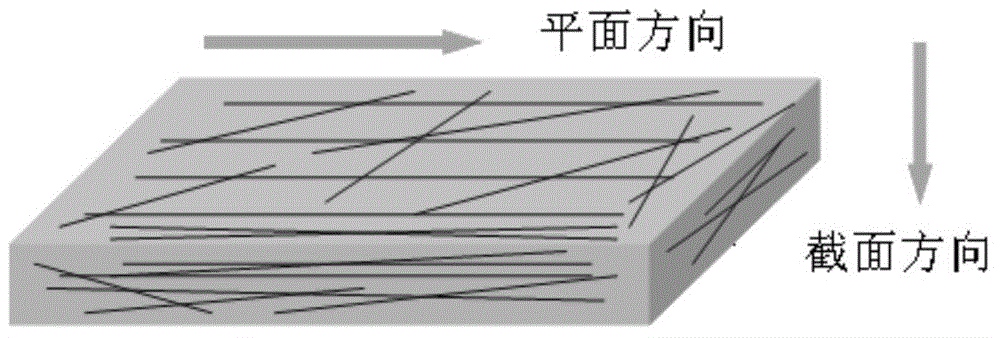

[0022] (2) Pour the fiber slurry into the suction filtration device three times in batches, and filter slowly, so that the residence time of the fibers in the solution is 5 minutes, and the degree of fiber distribution in the filter cake along the plane direction is improved; after completion, Press the filter cake on the press to a thickness of 22mm;

[0023] (3) Put the filter cake in (2) into an oven, heat treatment at 60°C for 10 hours to remove the solvent in the filter cake;

[0024] (4) Put the dried filter cake into a muffle furnace and heat it at 180°C for 3 hours to crosslink and solidify the polymethylsilsesquioxane;

[0025] (5) Put the material in (4) into a high-temperature furnace and heat-treat it in an argon atmosphere at 1000°C for 8 hours to ob...

Embodiment 2

[0029] (1) Mix 30g of polycarbosilane with 9g of divinylbenzene, add 250mL of xylene, stir and mix well;

[0030] (2) Mix 120g chopped silicon carbide fibers and 10g quartz fibers with 100g absolute ethanol and add them to (1), stir vigorously for 20 minutes to obtain ceramic fiber slurry;

[0031] (3) Pour the fiber slurry into the suction filtration device three times in batches, and filter slowly, so that the residence time of the fibers in the solution is 6 minutes, and the degree of fiber distribution in the filter cake along the plane direction is improved; after completion, Press the filter cake on the press to a thickness of 18mm;

[0032] (4) Put the (3) filter cake in an oven, heat treatment at 80°C for 4 hours to remove excess solvent;

[0033] (5) Put the dried filter cake into a muffle furnace and heat it at 240°C for 4 hours to crosslink and solidify the polycarbosilane;

[0034] (6) Put the material in (5) into a high-temperature furnace and heat-treat it in an argon atm...

Embodiment 3

[0037] (1) Mix 300g of chopped silicon carbide fiber and 50g of alumina fiber with 3500g of absolute ethanol, add 650g of polymethylsilsesquioxane, transfer to a mixer, stir vigorously for 25 minutes to mix evenly, and obtain ceramic fiber Slurry

[0038] (2) Pour the fiber slurry into the suction filtration device in batches for 5 times, and filter slowly, so that the residence time of the fiber in the solution is 8 minutes, and the degree of fiber distribution in the filter cake along the plane direction is improved; after completion, Press the filter cake on the press to a thickness of 32mm;

[0039] (3) Put the filter cake in an oven, heat treatment at 110°C for 4 hours to remove excess solvent;

[0040] (4) Put the dried filter cake into a muffle furnace, heat treatment at 300°C for 5 hours to crosslink and solidify the polymethylsilsesquioxane;

[0041] (5) Put the material in (4) into a high-temperature furnace and heat-treat it in an argon atmosphere at 1200°C for 5 hours to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity at room temperature | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com