High-voltage chip-type conductive polymer solid electrolyte tantalum capacitor and manufacturing method thereof

A conductive polymer, solid electrolyte technology, applied in solid electrolytic capacitors, capacitor electrodes, capacitor parts and other directions, can solve problems such as inability to meet the use, to meet the needs of high voltage, expand the scope of applications, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

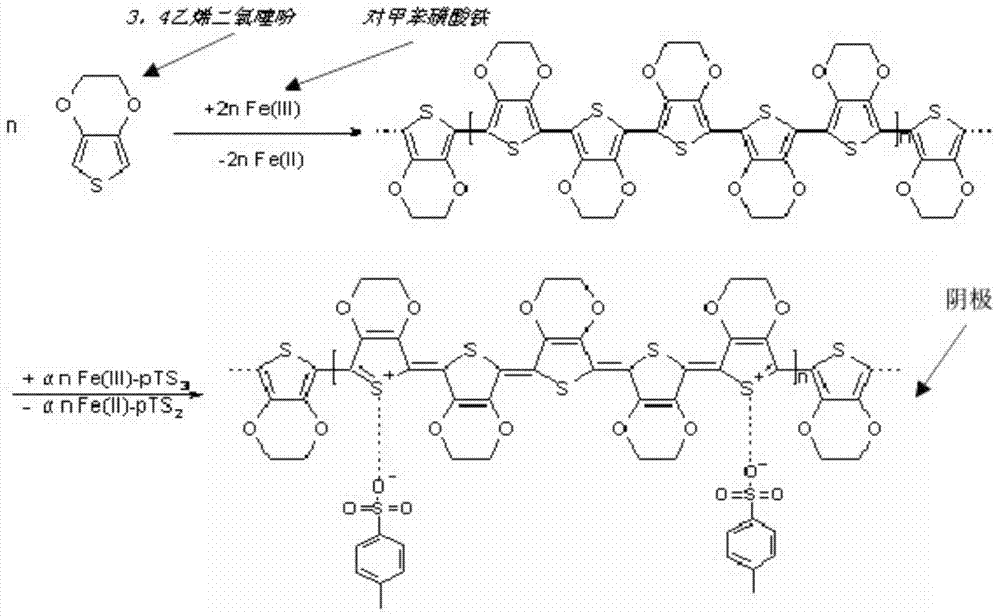

Method used

Image

Examples

Embodiment 1

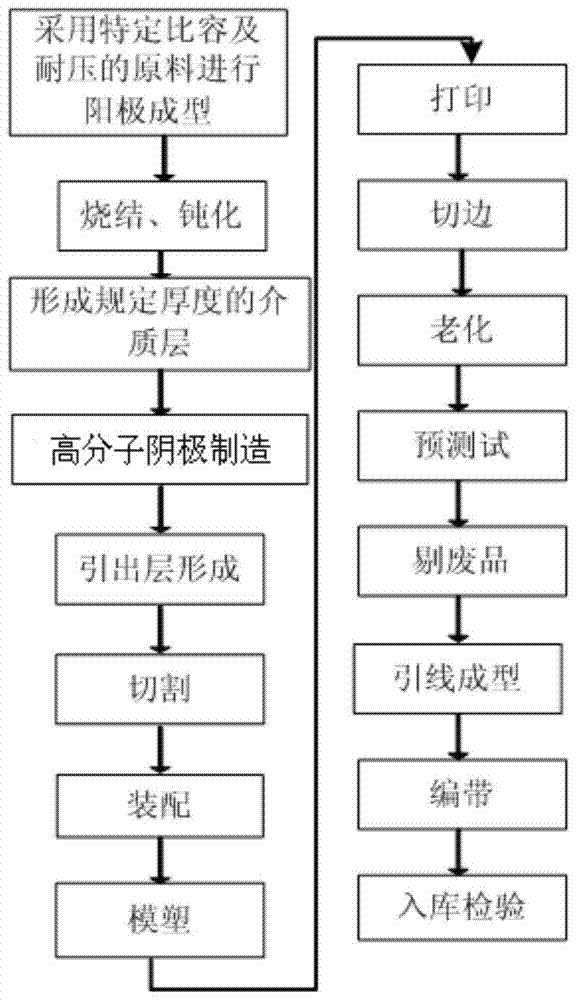

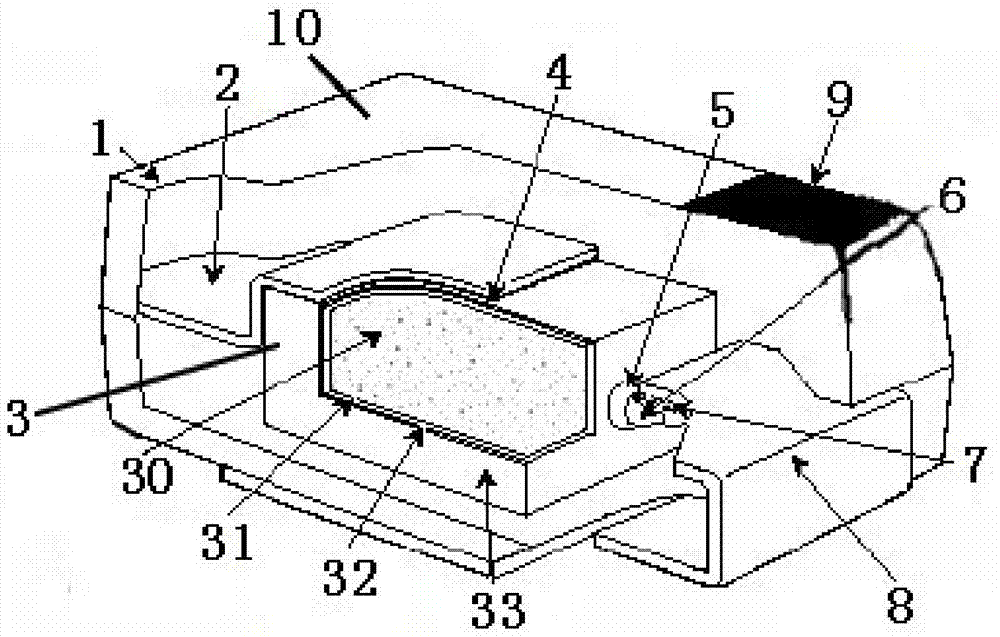

[0043] This embodiment provides a method for manufacturing a high-voltage chip-type conductive polymer solid electrolyte tantalum capacitor. It is a method for manufacturing a high-voltage organic polymer solid chip tantalum electrolytic capacitor. The rated withstand voltage of the capacitor can reach 50v. The structure of the capacitor is as image 3 shown, including:

[0044] A capacitor tantalum core substrate 3, a brass-based tin-plated negative electrode 2 and a brass-based tin-plated positive electrode 8 are arranged in the molded shell 1, and each part is encapsulated by epoxy resin. The inside of the capacitor tantalum core substrate 3 is a tantalum core as an anode, and the anode The surface is a cathode, and a dielectric layer with a thickness of not less than 3500 nanometers ( figure 2 not shown in), the anode is provided with a tantalum wire lead-out wire 6, the surface of the cathode is coated with a graphite layer 32 and a silver paste layer in turn as the cat...

Embodiment 2

[0060] This embodiment provides a method for manufacturing a high-voltage chip-type conductive polymer solid electrolyte tantalum capacitor. It is a method for manufacturing a high-voltage organic polymer solid-state chip tantalum electrolytic capacitor. The rated withstand voltage of the capacitor can reach 63v. Example The specification is 63V 4.7uF, the structure of this capacitor is as image 3 As shown, can refer to the description of a pair of capacitor structures in the embodiment, the difference is that the thickness of the dielectric layer on the anode block is 4400 nanometers, which will not be repeated here, and the steps of the manufacturing method are as follows:

[0061] (1) Use electron-bombed tantalum powder with a specific volume of 8000UuF.v / g and a breakdown voltage of more than 300V as raw material, and press it into a tantalum core block with a tantalum wire lead-out wire according to a pressing density of 7.5 g / CC (ie Anode block), according to the size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com