High-salt epoxy wastewater treatment method

A waste water treatment, epoxy technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

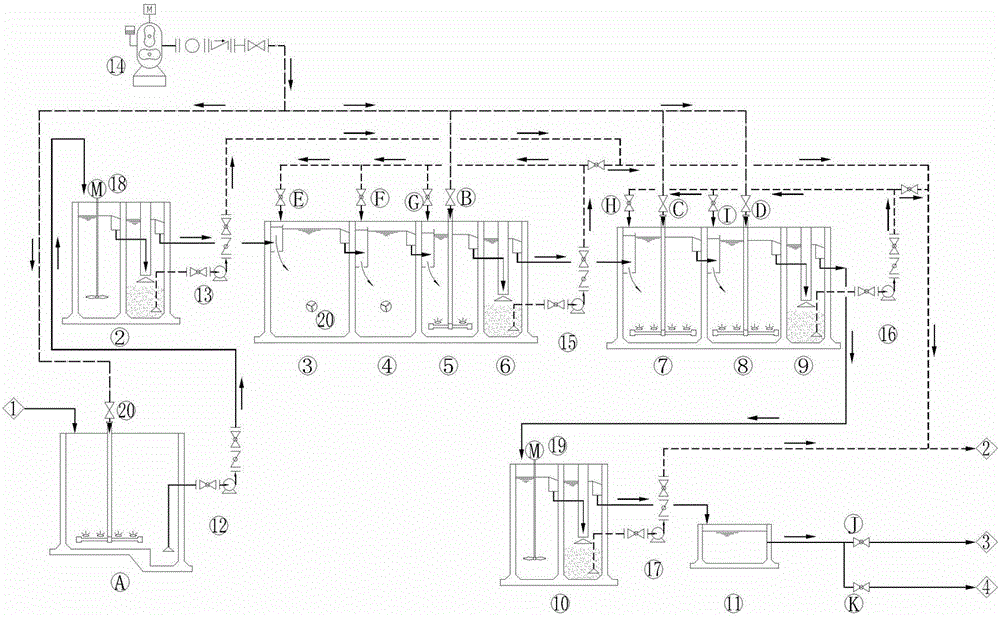

[0021] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments

[0022] Such as figure 1 , One A high-salt epoxy wastewater treatment method. The main steps are: firstly, adjust tank 1 to receive workshop production wastewater, start lifting pump 12, and then raise the wastewater to coagulation sedimentation tank 2, add PAC and PAM to coagulation sedimentation tank 2, and start them simultaneously Mixer 18, after coagulation for 10-15 minutes, the wastewater flows into the sedimentation tank, the supernatant of the sedimentation tank flows into the hydrolysis tank 3, and the bottom sediment is sent to the sludge frame dewatering 21 through the sludge pump 13 to prevent sedimentation in the adjustment tank 1. The origin of the bottom intermittent aeration comes from the blower 14; secondly, after the wastewater is hydrolyzed in the hydrolysis tank 3, it flows into the acidification tank 4 by itself, and sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com