Fire retardant 4-oxygen same-cage diphosphine phosphite ester compound and preparing method thereof

A technology of bisphosphorous phosphite and phosphite triester, which is applied in the field of organic phosphine flame retardant 4-oxygen co-cage bisphosphorous phosphite compound and its preparation, can solve the safety hazards of toxic gas and smoke, and halogen-based flame retardants. In order to achieve good environmental and economic benefits, easy large-scale conversion and production, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

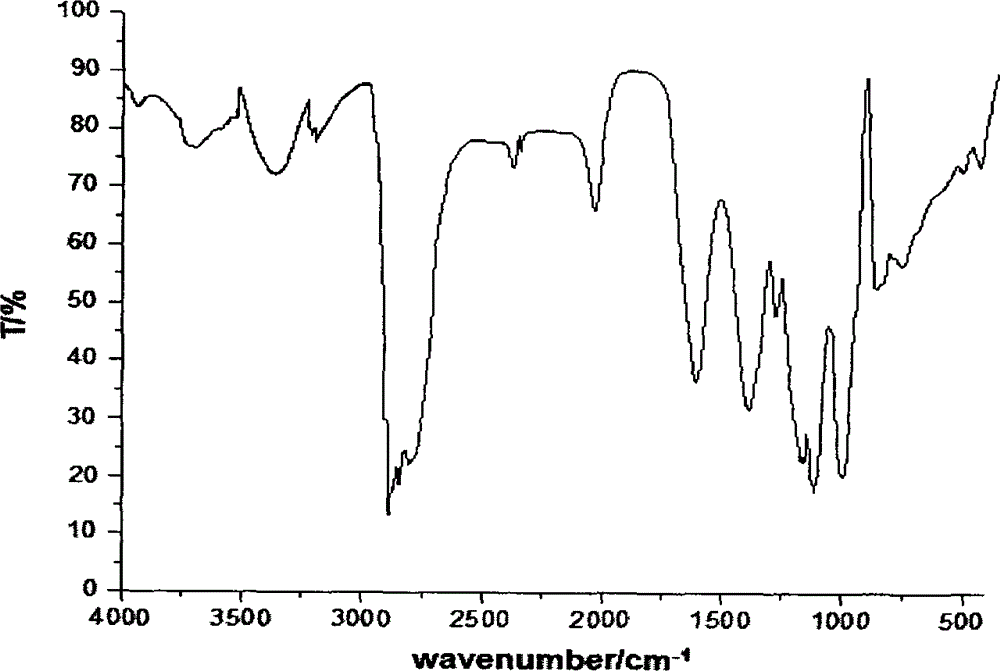

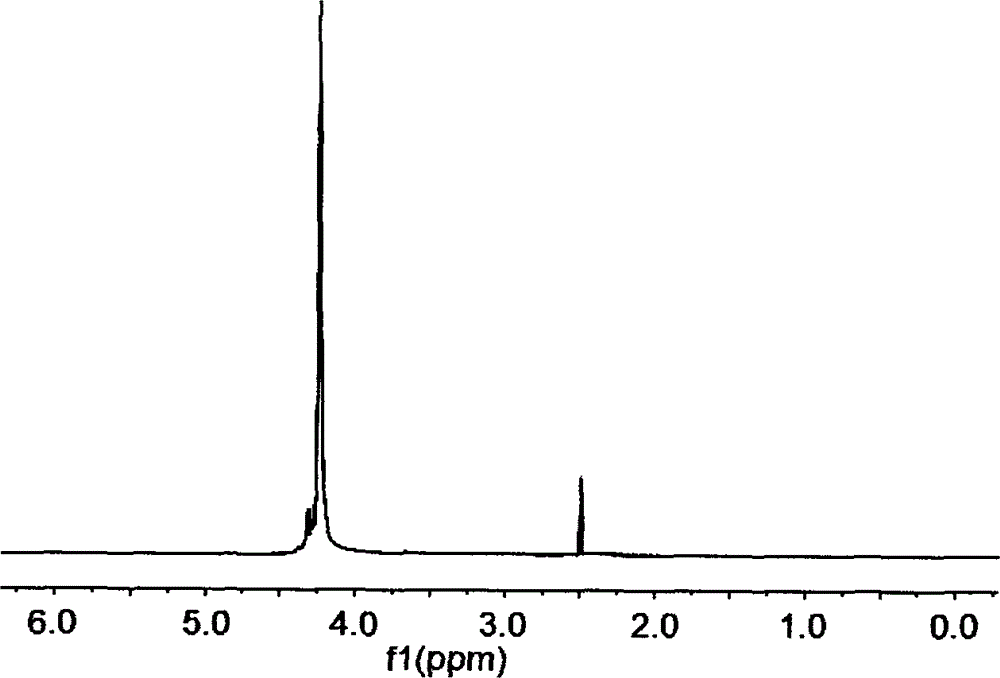

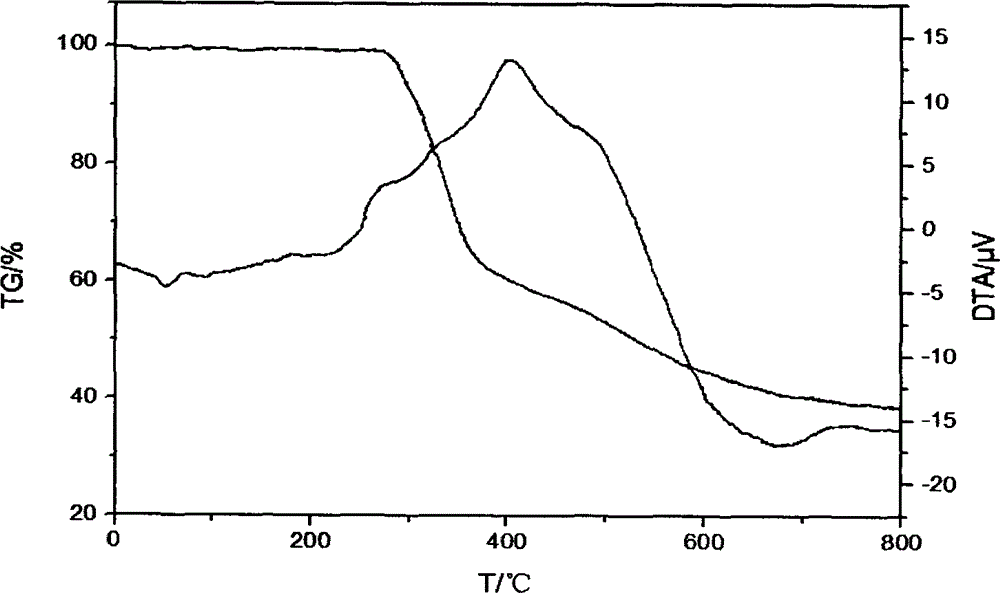

Embodiment 1

[0031] Example 1 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, use nitrogen to exhaust the air in the bottle, add 14.00g (0.1mol) trishydroxymethyl phosphine oxide and 12.40g (0.1mol) Trimethyl phosphite. Under stirring, add 0.28g of triethylamine catalyst, heat and continue to feed nitrogen, heat up to 110°C for 9 hours, keep the temperature at the top of the column not higher than 65°C, and fractionally distill out the methanol produced by the reaction (recycled). Stop the reaction when the fraction reaches the theoretical amount, lower the temperature to below 20°C, add 50ml of ice water, stir for 30 minutes, disperse the white granular solid product in water, filter, rinse the filter cake with 10ml of ice water, compact and drain, and vacuum the filter cake Dry to obtain white solid 4-oxocage bisphosphorous acid ester with a yield of 92.5%, melting point: 82±2°C, and decomposition temperature: 273±5°C.

Embodiment 2

[0032] Example 2 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, use nitrogen to exhaust the air in the bottle, add 14.00g (0.1mol) trishydroxymethyl phosphine oxide and 12.40g (0.1mol) Trimethyl phosphite. Under stirring, add 0.14g of pyridine catalyst, heat and continue to feed nitrogen, heat up to 120°C for 8 hours, always control the column top temperature not higher than 65°C, fractionally distill out the methanol produced by the reaction (recycling), when the methanol fraction reaches Stop the reaction when the theoretical amount is reached, lower the temperature to below 20°C, add 45ml of ice water, stir for 30 minutes, disperse the white granular solid product in water, filter, rinse the filter cake with 10ml of ice water, compact and drain, and vacuum dry the filter cake. The white solid 4-oxocage diphosphite was obtained with a yield of 93.3%, a melting point of 82±2°C and a decomposition temperature of 2...

Embodiment 3

[0033] Example 3 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, the air in the bottle was driven out with nitrogen, and 14.00g (0.1mol) of trishydroxymethylphosphine oxide and 12.40g (0.1mol) of trihydroxymethylphosphine oxide were added. Trimethyl phosphite. Under stirring, add 0.15g of sodium methoxide catalyst, heat and continue to feed nitrogen, raise the temperature to 130°C for 7 hours, always control the column top temperature not higher than 65°C, fractionally distill out the methanol produced by the reaction (recovered for use), and use it as methanol fraction Stop the reaction when the theoretical amount is reached, lower the temperature to below 20°C, add 40ml of ice water, stir for 30 minutes, disperse the white granular solid product in water, filter, rinse the filter cake with 10ml of ice water, compact and drain, and vacuum dry the filter cake , to obtain white solid 4-oxo caged bisphosphorous acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com