A kind of styrene modified alkyd resin and preparation method thereof

A technology of alkyd resin and styrene, applied in the field of styrene-modified alkyd resin and its preparation, to achieve the effect of increasing drying speed, increasing hardness, and accelerating the drying process of coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

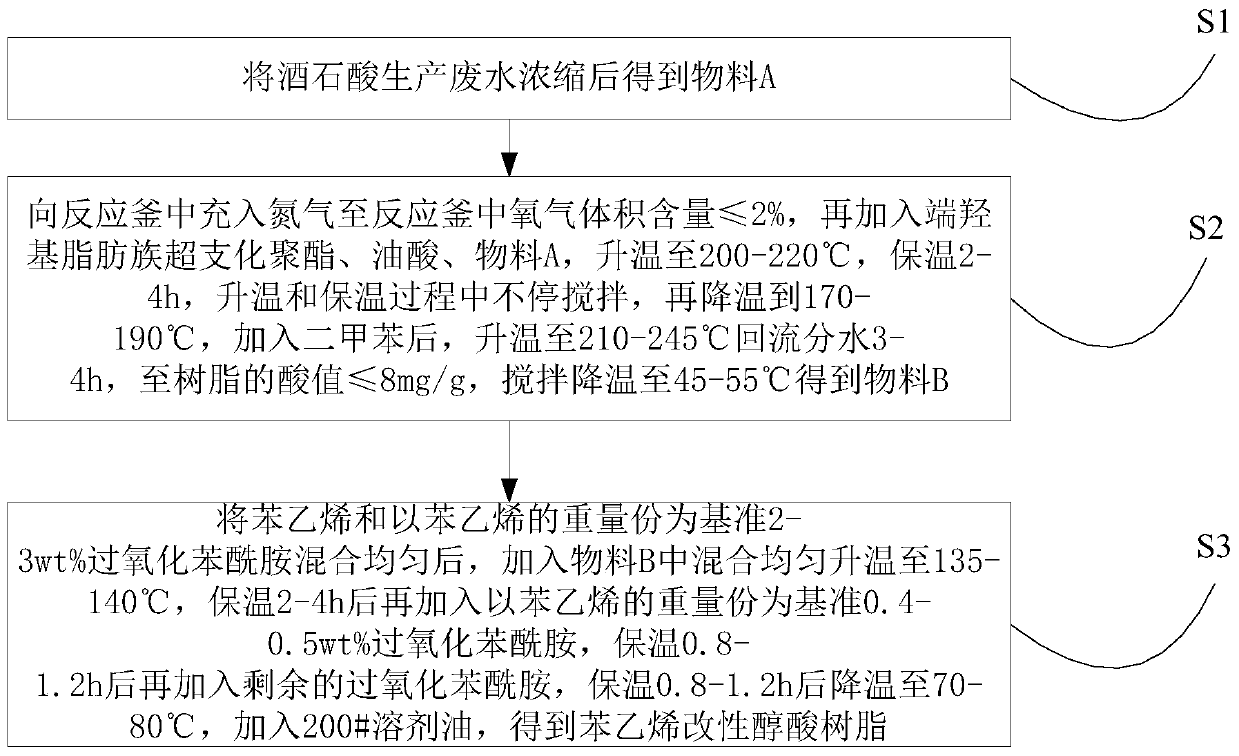

[0022] refer to figure 1 , the preparation method of the above-mentioned styrene-modified alkyd resin that the present invention also proposes, comprises the steps:

[0023] S1, obtain material A after concentrating tartaric acid production wastewater;

[0024] S2. Fill the reactor with nitrogen until the oxygen volume content in the reactor is ≤2%, then add hydroxyl-terminated aliphatic hyperbranched polyester, oleic acid, and material A, heat up to 200-220°C, keep warm for 2-4h, and heat up Stir continuously during the heat preservation process, then lower the temperature to 170-190°C, add xylene, raise the temperature to 210-245°C, reflux and separate water for 3-4h, until the acid value of the resin is ≤8mg / g, stir and cool down to 45-55 °C to obtain material B;

[0025] S3. After mixing styrene and 2-3wt% benzamide peroxide based on the weight of styrene, add material B and mix evenly to raise the temperature to 135-140°C, keep warm for 2-4h, and then add styrene The p...

Embodiment 1

[0028] A kind of styrene-modified alkyd resin proposed by the present invention, its raw material comprises by weight: 50 parts of hydroxyl-terminated aliphatic hyperbranched polyesters, 40 parts of oleic acid, 70 parts of tartaric acid production wastewater, 6 parts of xylene, styrene 25 parts, 1.2 parts of benzamide peroxide, 30 parts of 200# solvent naphtha.

[0029] The preparation method of the above-mentioned styrene-modified alkyd resin that the present invention also proposes comprises the steps:

[0030] S1, concentrating tartaric acid production waste water to the mass concentration of tartaric acid is 30g / L and obtains material A;

[0031] S2. Fill the reactor with nitrogen until the volume content of oxygen in the reactor is ≤2%, then add hydroxyl-terminated aliphatic hyperbranched polyester, oleic acid, and material A, raise the temperature to 215°C, and keep it warm for 2.5 hours. Stir continuously in the middle, then cool down to 185°C, add xylene, heat up to 2...

Embodiment 2

[0034] A kind of styrene-modified alkyd resin that the present invention proposes, its raw material comprises by weight: 60 parts of hydroxyl-terminated aliphatic hyperbranched polyesters, 20 parts of oleic acid, 80 parts of tartaric acid production wastewater, 2 parts of xylene, styrene 30 parts, 0.7 part of benzamide peroxide, 50 parts of 200# solvent naphtha, wherein the tartaric acid mass concentration in the tartaric acid production wastewater is 1.5g / L.

[0035] The preparation method of the above-mentioned styrene-modified alkyd resin that the present invention also proposes comprises the steps:

[0036] S1, the mass concentration that tartaric acid production waste water is concentrated to tartaric acid is 32g / L and obtains material A;

[0037] S2. Fill the reactor with nitrogen until the volume content of oxygen in the reactor is ≤2%, then add hydroxyl-terminated aliphatic hyperbranched polyester, oleic acid, and material A, heat up to 210°C, and keep warm for 3 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com