High coercivity low dysprosium (terbium) NdFeB magnet based on crystal boundary modification

A technology of NdFeB and intrinsic coercive force, applied in the direction of magnetic objects, magnetic materials, permanent magnets, etc., can solve the problems of restricting coercive force, hindering the intrinsic coercive force of magnets, and weakening the magnetic isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

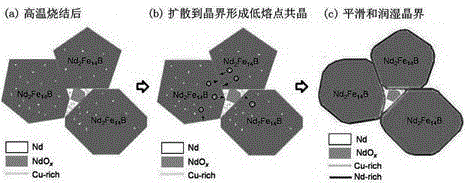

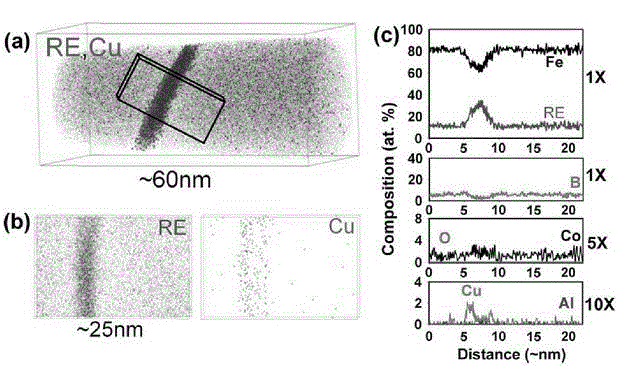

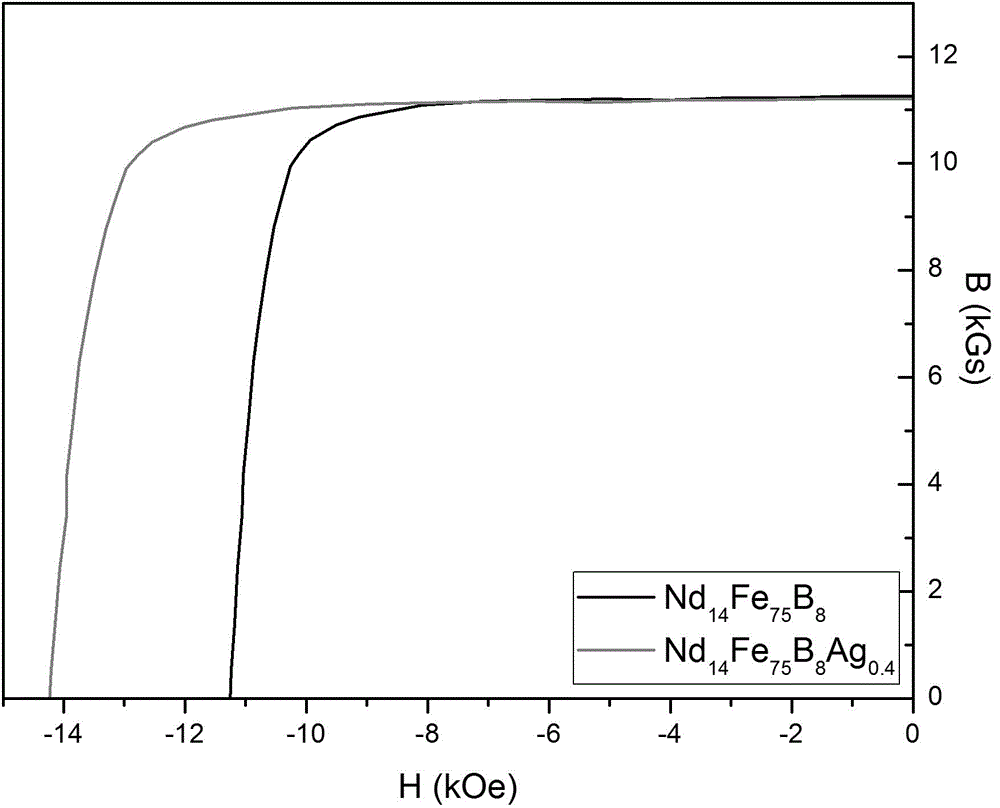

[0016] According to chemical formula Nd 14 Fe 75 B 8 、Nd 14 Fe 75 B 8 Ag 0.4 Prepare the alloy and carry out vacuum smelting. The smelted alloy is homogenized and annealed at 1110 degrees Celsius for 16 hours. After mechanical crushing, use a jet mill to make powder and check that the particle size of the powder is less than 10 μm. Then the powder is oriented and pressed in a 2 T magnetic field. After molding, put the compact into a vacuum sintering furnace and sinter at 1050 degrees Celsius for 4 hours. After the sintering is completed, perform secondary heat treatment, wherein the primary heat treatment temperature is 950 degrees Celsius for 2 hours, and the secondary heat treatment temperature is 650 degrees Celsius for 1 hour. The magnetic performance indexes of the prepared magnets are listed in Table 1, and the demagnetization curves are shown in image 3 In , the composition distribution at the grain boundary is as follows Figure 4 (The process in this example c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com