A kind of dehydrogenation catalyst and its preparation and use method

A dehydrogenation catalyst, catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems to be improved, and achieve significant social and economic benefits. benefit, optimize utilization, mitigate the effects of increased demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

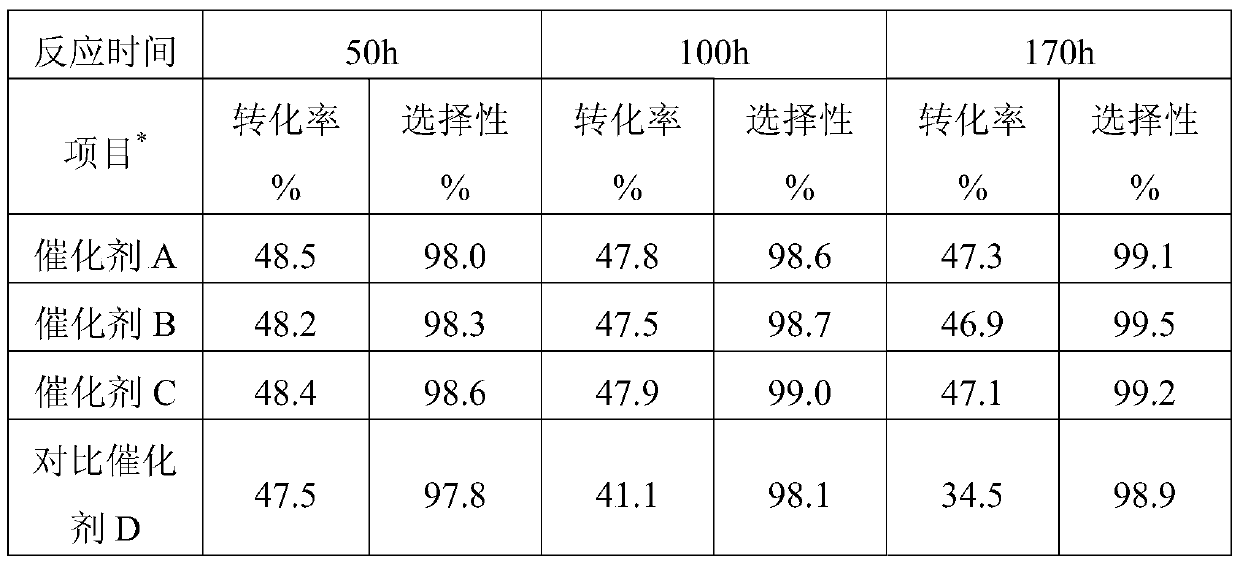

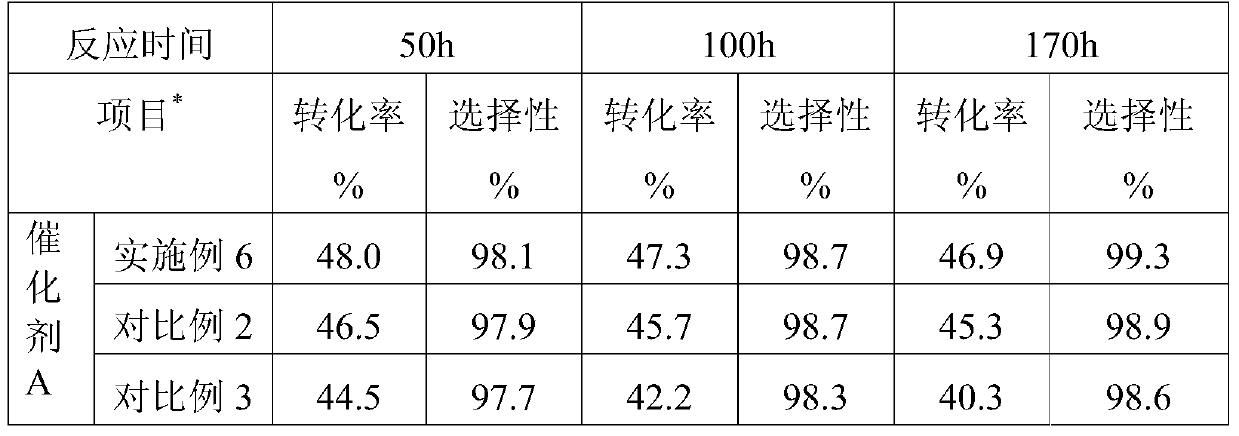

Examples

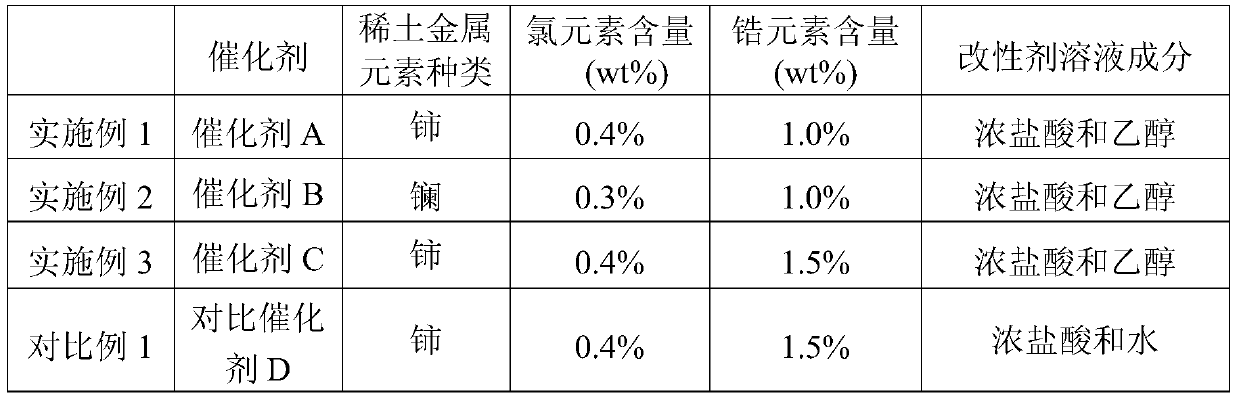

Embodiment 1

[0037] The present invention uses γ-Al 2 o 3 The carrier is prepared by known methods, and can be processed into any form by known methods. What this embodiment used is the average length 4mm, the bar shape γ-Al of average diameter 2mm 2 o 3 .

[0038] Take the strip γ-Al 2 o 3 The cerium nitrate solution is impregnated by an equal volume impregnation method, so that the carrier is loaded with cerium, dried at 120°C for 10 hours, and calcined at 600°C for 6 hours.

[0039] The above-mentioned cerium-loaded strip-shaped γ-Al 2 o 3 The carrier is impregnated with a solution of potassium nitrate and magnesium nitrate in an equal volume, so that the carrier is loaded with potassium and magnesium, dried at 120° C. for 10 hours, and calcined at 600° C. for 6 hours.

[0040] The strip-shaped γ-Al loaded with metal cerium, potassium and magnesium 2 o 3 The carrier is then impregnated with ethanol hydrochloric acid solution containing platinum salt, tin salt and zirconium sal...

Embodiment 2

[0043] Take a spherical γ-Al with a diameter of 2mm 2 o 3 The lanthanum nitrate solution is impregnated by an equal volume impregnation method, so that the carrier is loaded with lanthanum, dried at 120°C for 10 hours, and calcined at 600°C for 6 hours.

[0044] The above-mentioned spherical γ-Al loaded with lanthanum 2 o 3 The carrier is impregnated with a solution of potassium nitrate and magnesium nitrate in an equal volume, so that the carrier is loaded with potassium and magnesium, dried at 120° C. for 10 hours, and calcined at 600° C. for 6 hours.

[0045] The above spherical γ-Al loaded with lanthanum, potassium and magnesium 2 o 3 The carrier is impregnated with an equal volume of hydrochloric acid ethanol solution containing platinum salt, tin salt and zirconium salt, wherein the volume ratio of concentrated hydrochloric acid (36-38% by mass) and absolute ethanol in the hydrochloric acid ethanol solution is 1:3, The carrier is loaded with platinum, tin and zircon...

Embodiment 3

[0048] Take a clover-shaped γ-Al with a length of 4mm and a diameter of 2mm 2 o 3 The cerium nitrate solution is impregnated by an equal volume impregnation method, so that the carrier is loaded with cerium, dried at 120°C for 10 hours, and calcined at 600°C for 6 hours.

[0049] The above-mentioned clover-like γ-Al loaded with metal cerium ions 2 o 3 The carrier is impregnated with a solution of potassium nitrate and magnesium nitrate in an equal volume, so that the carrier is loaded with potassium and magnesium, dried at 120° C. for 10 hours, and calcined at 600° C. for 6 hours.

[0050] The above-mentioned γ-Al strips loaded with cerium, potassium and magnesium 2 o 3 The carrier is impregnated with an equal volume of hydrochloric acid ethanol solution containing platinum salt, tin salt and zirconium salt, wherein the volume ratio of concentrated hydrochloric acid (36-38% by mass) and absolute ethanol in the hydrochloric acid ethanol solution is 2:4, Make the carrier lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com