Process for preparing 4-propylthio-o-phenylenediamine

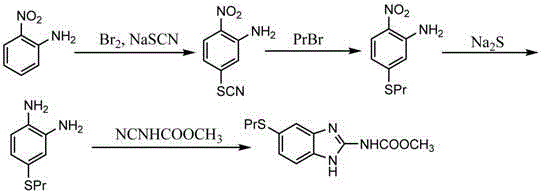

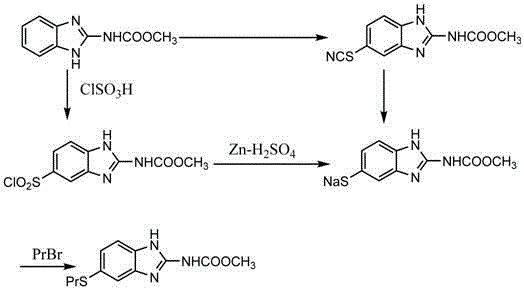

A kind of propylthio-o-phenylenediamine and the technology of preparation steps, which are applied in the field of preparation technology of 4-propylthio-o-phenylenediamine, a key intermediate in the synthesis of albendazole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

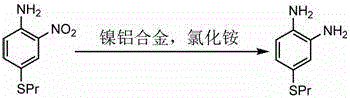

Image

Examples

Embodiment 1

[0024] Dissolve ammonium chloride (13 g, 0.25 mol) in water (100 mL), add 2-nitro-4-propylthioaniline (21.2 g, 0.1 mol), and slowly add nickel in batches under stirring at 80-90 °C Aluminum alloy (20 g, 0.2 mol). After adding, continue to react at the same temperature, follow the completion of the reaction with thin-layer chromatography, suction filter the reaction mixture while it is hot, and wash the filter residue with a small amount of hot water, cool the filtrate, extract with ethyl acetate, combine the ester layers, wash with water, anhydrous sulfuric acid Sodium drying and rotary evaporation gave 17.4 g of 4-propylthio-o-phenylenediamine with a yield of 95.6%.

Embodiment 2

[0026] Dissolve ammonium chloride (13 g, 0.25 mol) in water (100 mL), add 2-nitro-4-propylthioaniline (21.2 g, 0.1 mol), and slowly add nickel in batches under stirring at 80-90 °C Aluminum alloy (10 g, 0.1 mol). After adding, continue to react at the same temperature, follow the completion of the reaction with thin-layer chromatography, suction filter the reaction mixture while it is hot, and wash the filter residue with a small amount of hot water, cool the filtrate, extract with dichloromethane, combine the organic layers, wash with water, anhydrous sulfuric acid Sodium drying and rotary evaporation gave 17 g of 4-propylthio-o-phenylenediamine with a yield of 93.4%.

Embodiment 3

[0028] Dissolve ammonium chloride (21.8 g, 0.4 mol) in water (100 mL), add 2-nitro-4-propylthioaniline (21.2 g, 0.1 mol), and slowly add nickel in batches under stirring at 80-90 °C Aluminum alloy (20 g, 0.2 mol). After the addition, continue to react at the same temperature, track the completion of the reaction with thin layer chromatography, suction filter the reaction mixture while it is hot, and wash the filter residue with a small amount of hot water, cool the filtrate, extract with chloroform, combine the organic layers, wash with water, and dry over anhydrous sodium sulfate , rotary evaporation, 17.6 g of 4-propylthio-o-phenylenediamine was obtained, and the yield was 96.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com