Sulfonylation graphene oxide magnetic adsorbent, and preparation method and application thereof

A magnetic adsorbent, graphene technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problem of reduced adsorption sites, limited number of groups, and reduced adsorption capacity and other problems, to achieve the effect of many adsorption sites, easy separation and recovery, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

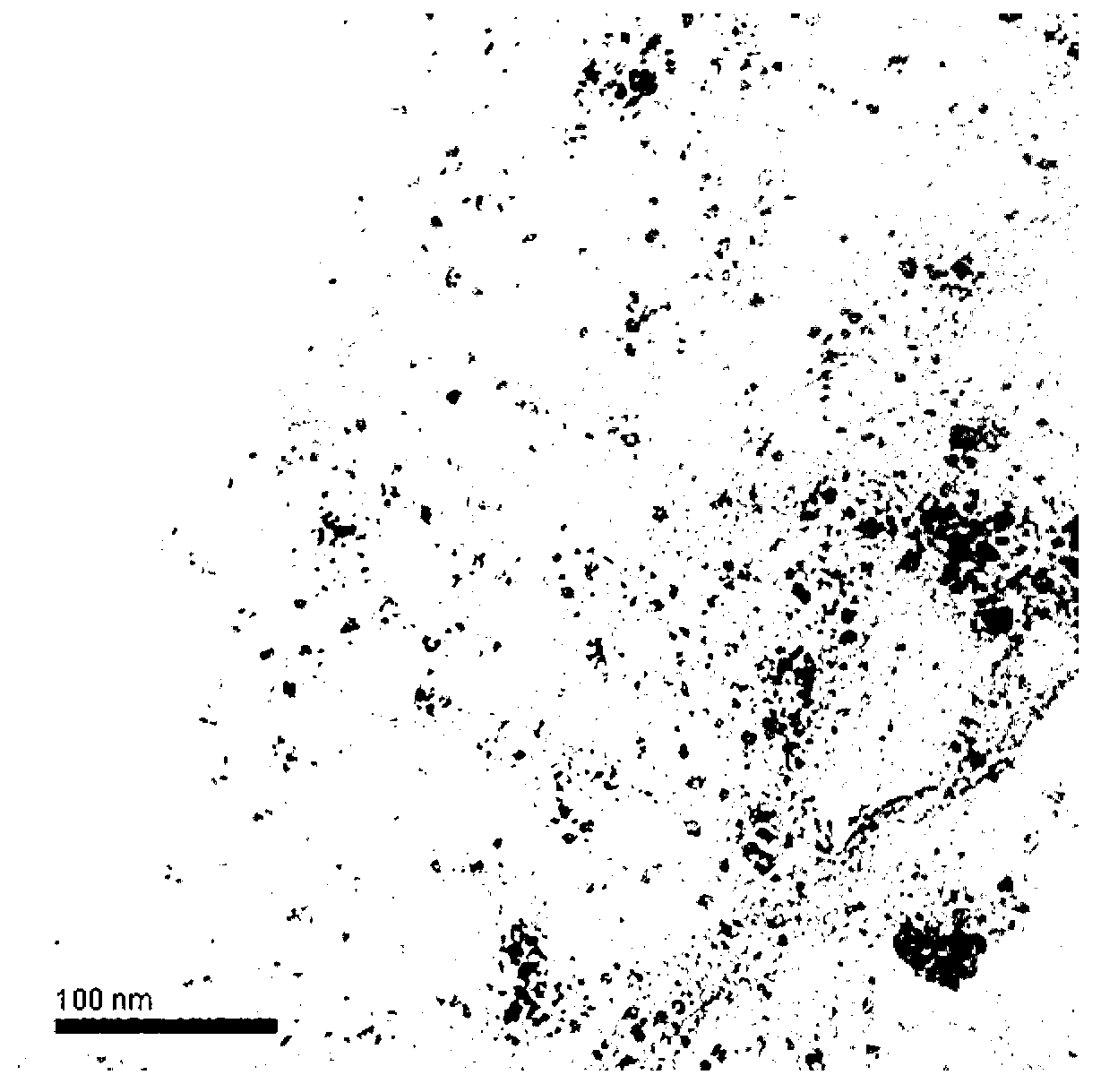

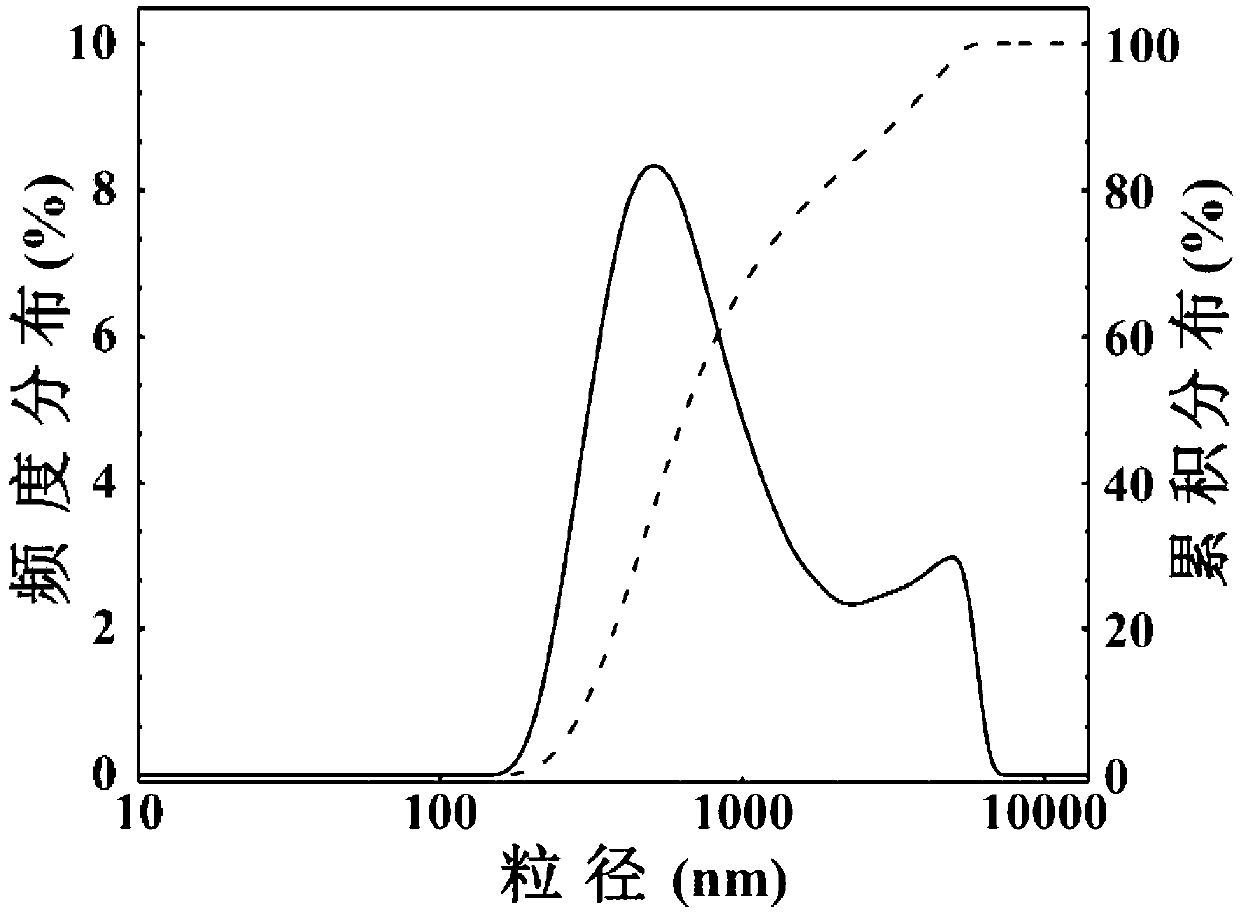

[0026] A sulfonated graphene oxide magnetic adsorbent according to the present invention, the adsorbent includes a graphene oxide substrate, the substrate is loaded with magnetic ferrite nanoparticles and has a large number of sulfonic acid groups. The sulfonated graphene oxide magnetic adsorbent is prepared by the following method:

[0027] 6 g graphite powder, 5 g K 2 S 2 o 4 and 5 g P 2 o 5 Add it to 24 mL of concentrated sulfuric acid with a concentration of 98%, react at 80 °C for 4.5 hours, add 1000 mL of ultrapure water after cooling to room temperature, and wash the obtained product to neutrality after standing for 12 hours, then dry it at 60 °C Pre-oxidized graphene was obtained; the obtained pre-oxidized graphite was added to 240 mL of concentrated sulfuric acid with a concentration of 98%, and then 5 g of NaNO 3 and 30 g KMnO 4 , react at 0 °C for 4 hours, heat up to 35 °C for 2 hours, add 500 mL of ultrapure water, react at 98 °C for 1 hour, then add 1000 mL ...

Embodiment 2

[0032] The sulfonated graphene oxide magnetic adsorbent of the present invention is used to adsorb and treat copper ions in wastewater, comprising the following steps: taking 50 mL of Cu with an initial concentration of 5 to 100 mg / L 2+ solution, adjust the pH value of the solution to 5.0, add the sulfonated graphene oxide magnetic adsorbent prepared in Example 1, the amount of this adsorbent is 0.18 g / L, carry out the oscillation adsorption reaction at 30 ℃ of air bath constant temperature oscillator After 6 hours, the adsorbent was separated from the wastewater with a magnet, and the unadsorbed Cu in the wastewater was determined by flame atomic absorption method. 2+ The content of the calculated adsorption capacity is shown in Table 1:

[0033] Table 1: Different Cu 2+ The adsorption capacity data of the adsorbent under the condition of initial concentration

[0034]

[0035] It can be seen from Table 1 that the adsorbent has an adsorption capacity of 19.34 mg / g under ...

Embodiment 3

[0037] The sulfonated graphene oxide magnetic adsorbent of the present invention is used for adsorption and treatment of cadmium ions in wastewater, comprising the following steps: taking 20 mL of Cd with an initial concentration of 10 mg / L 2+ Solution, adjust the pH value of the solution to 6.0, add the sulfonated graphene oxide magnetic adsorbent obtained in Example 1, the consumption of the adsorbent is 0.34 g / L, carry out the oscillation adsorption reaction at 30 ℃ of water bath constant temperature oscillator, After 24 hours, the adsorbent was separated from the wastewater with a magnet, and the unadsorbed Cd in the wastewater was determined by flame atomic absorption spectrometry 2+ content, the adsorption capacity of this product to cadmium is 18.85 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com