Preparation method of paper for industry

A paper and industrial technology, which is applied in the field of industrial paper preparation, can solve the problems of waste of resources, poor toughness, large investment in equipment, etc., to improve water resistance and moisture resistance, increase toughness and softness, pretreatment short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

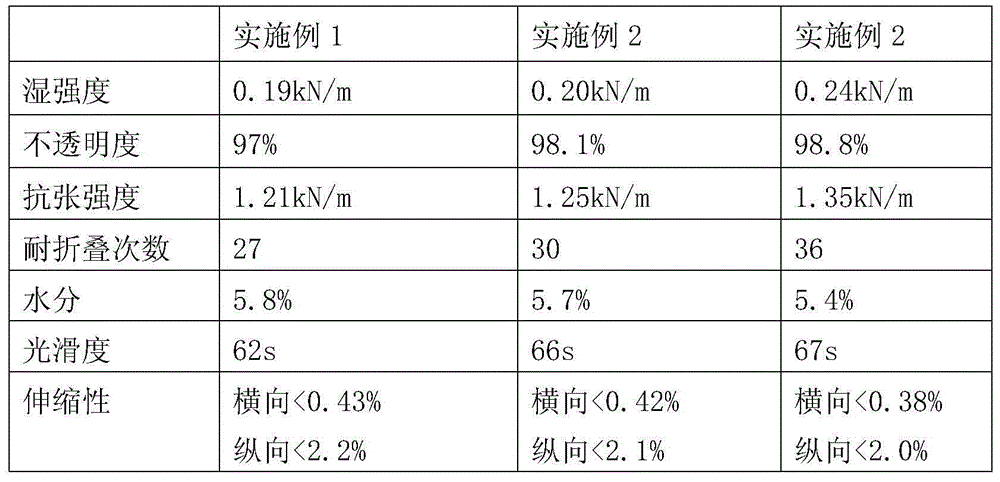

Examples

Embodiment 1

[0017] A method for preparing industrial paper, comprising the following methods:

[0018] (1) Raw material processing: cutting and cleaning the raw materials for preparing the paper, sending them into pulp for crushing and disintegration, separating and removing dust, and making 0.2-0.5mm fiber raw materials; the raw materials for preparing the paper are straw One or more mixtures of wood, reed or bamboo;

[0019] (2) Soaking: Put the raw material of fiber filaments into a soaking tank filled with chemical agents for soaking. The temperature during soaking is 25-35°C. Stir continuously during the soaking process. After soaking for 3-4 hours, add paraffin for stirring. And slowly heated to 90-100 ° C and kept for 15-20 minutes, that is, after cooling, the coarse slurry was obtained; in the embodiment of the present invention, the stirring speed during the soaking is above 3000 rpm, which improves the fineness of the paper;

[0020] (3) Washing paper: put the coarse slurry obt...

Embodiment 2

[0025] A method for preparing industrial paper, comprising the following methods:

[0026] (1) Raw material processing: cutting and cleaning the raw materials for preparing the paper, sending them into pulp for crushing and disintegration, separating and removing dust, and making 0.2-0.5mm fiber raw materials; the raw materials for preparing the paper are straw One or more mixtures of wood, reed or bamboo;

[0027] (2) Soaking: Put the raw material of fiber filaments into a soaking tank filled with chemical agents for soaking. The temperature during soaking is 25-35°C. Stir continuously during the soaking process. After soaking for 3-4 hours, add paraffin for stirring. And slowly heated to 90-100 ° C and kept for 15-20 minutes, that is, after cooling, the coarse slurry was obtained; in the embodiment of the present invention, the stirring speed during the soaking is above 4000 rpm, which improves the fineness and moisture resistance of the paper .

[0028] (3) Washing paper:...

Embodiment 3

[0033] A method for preparing industrial paper, comprising the following methods:

[0034] (1) Raw material processing: cutting and cleaning the raw materials for preparing the paper, sending them into pulp for crushing and disintegration, separating and removing dust, and making 0.2-0.5mm fiber raw materials; the raw materials for preparing the paper are straw One or more mixtures of wood, reed or bamboo;

[0035] (2) Soaking: Put the raw material of fiber filaments into a soaking tank filled with chemical agents for soaking. The temperature during soaking is 25-35°C. Stir continuously during the soaking process. After soaking for 3-4 hours, add paraffin for stirring. And slowly heated to 90-100 ° C and kept for 15-20 minutes, that is, after cooling, the coarse slurry was obtained; in the embodiment of the present invention, the stirring speed during the soaking was 4500 rpm to improve the fineness and flexibility of the paper , Moisture resistance;

[0036] (3) Washing pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com