Composite wood processing technique

A processing technology and wood technology, applied in textiles, papermaking, papermaking, fiberboard, etc., can solve the problems of small waste recycling range, short long-term usability of wood, and immature technology, so as to improve plasticity and curb growth , excellent effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

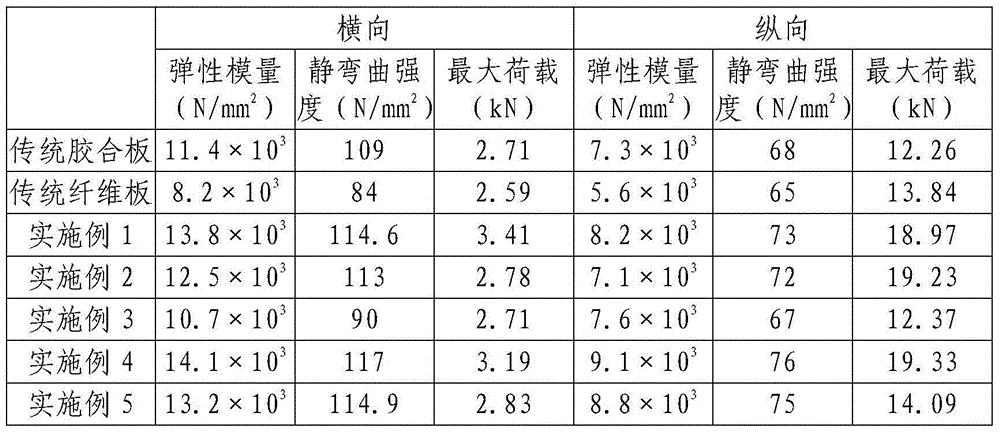

Examples

Embodiment 1

[0030] The invention relates to a processing technology of composite wood, the material selection of which is 12 parts of straw, 9 parts of sugarcane and 13 parts of sawdust.

[0031] The specific steps are:

[0032] (1) Put bagasse, straw, and sawdust in a steaming ball, cook with alkali, heat up for 68 minutes, add hydroxypropyl methylcellulose, and heat for 30 minutes to obtain a slurry;

[0033] (2) transfer the slurry to the mixer, add melamine for intermittent stirring, perform drying and molding once, and obtain the first composite wood product;

[0034] (3) Soaking the primary composite wood product, secondary drying, and surface coating to obtain the composite wood product.

[0035] The temperature raising treatment in the step (1) is to cook at a rate of 5°C every 10 minutes, and control the final cooking temperature to 76°C, and maintain the holding temperature at 70°C.

[0036] Adding alkali in the described step (1) is to add sodium hydroxide, sodium sulfide suc...

Embodiment 2

[0042] The invention relates to a processing technology of composite wood, the materials of which include 18 parts of straw, 11 parts of sugar cane and 33 parts of sawdust.

[0043] The specific steps are:

[0044] (1) Put bagasse, straw, and sawdust in a steaming ball, cook with alkali, heat up for 74 minutes, add hydroxypropyl methylcellulose, and heat for 30 minutes to obtain a slurry;

[0045] (2) transfer the slurry to the mixer, add melamine for intermittent stirring, perform drying and molding once, and obtain the first composite wood product;

[0046] (3) Soaking the primary composite wood product, secondary drying, and surface coating to obtain the composite wood product.

[0047] The temperature raising treatment in the step (1) is to cook at a rate of 5°C every 10 minutes, and control the final cooking temperature to 63°C, and maintain the holding temperature at 56°C.

[0048] Adding alkali in the described step (1) is that sodium hydroxide and sodium sulfide are ...

Embodiment 3

[0054] The invention relates to a processing technology of composite wood, the selected materials are 27 parts of straw, 26 parts of sugarcane and 25 parts of sawdust.

[0055] The specific steps are:

[0056] (1) Put bagasse, straw, and sawdust in a steaming ball, cook with alkali, heat up for 68 minutes, add hydroxypropyl methylcellulose, and heat for 30 minutes to obtain a slurry;

[0057] (2) transfer the slurry to the mixer, add melamine for intermittent stirring, perform drying and molding once, and obtain the first composite wood product;

[0058] (3) Soaking the primary composite wood product, secondary drying, and surface coating to obtain the composite wood product.

[0059]The temperature raising treatment in the step (1) is to cook at a rate of 5°C every 10 minutes, and control the final cooking temperature to 58°C, and maintain the holding temperature at 58°C.

[0060] Adding alkali in the described step (1) is that sodium hydroxide and sodium sulfide are added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com