Mini-sized supercapacitor with high flexibility and high transparency and large-scale preparation method of mini-sized supercapacitor

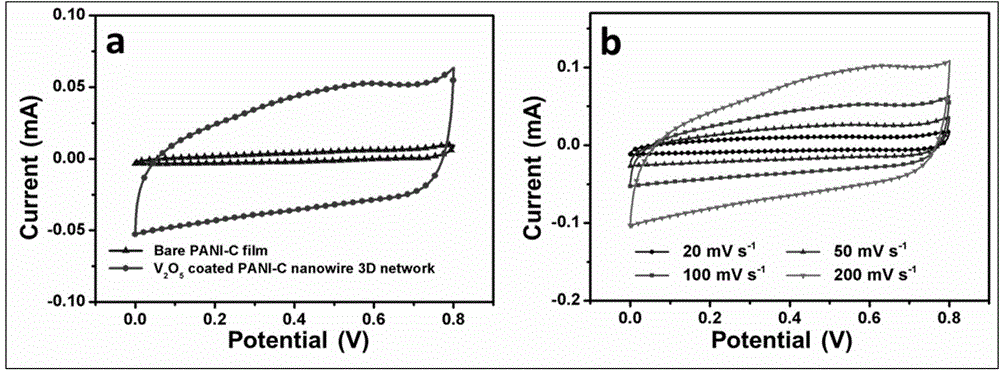

A supercapacitor, transparency technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of inability to prepare transparent flexible energy storage devices, low power density, etc., and achieve convenient, easy, high flexibility and high Transparency, improving energy and power density, enhancing the effect of pseudocapacitive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

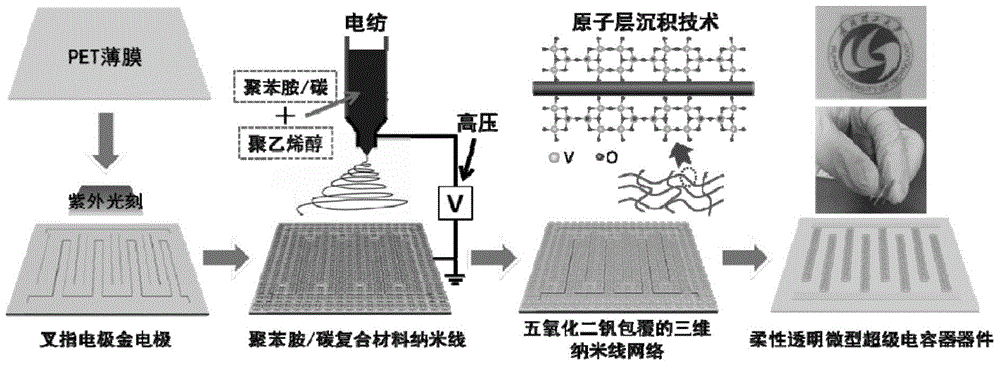

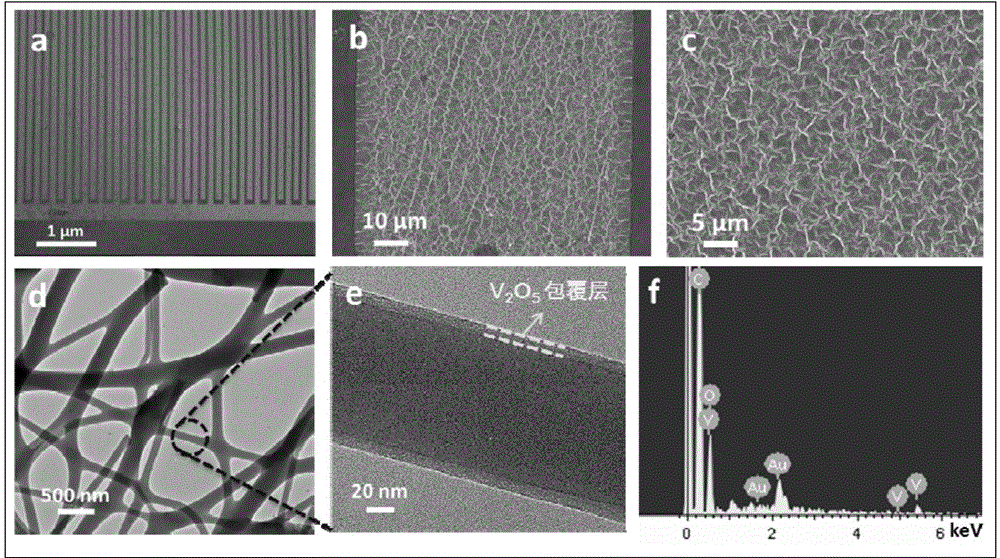

[0025] Such as figure 1 Shown, have the preparation method of highly flexible and transparent miniature supercapacitor, it comprises the following steps:

[0026] 1) Coat the photoresist LOR3A on the PET substrate with a coater at a speed of 4000rpm, and spin coating for 40s, then bake the glue with an electric heating plate at 185°C for 5min, and then coat the photoresist S1805 on the surface at a speed of 40s 4000rpm, spin-coating time is 40s, and then use a hot plate to bake the glue at 115°C for 5min;

[0027] 2) Using ultraviolet lithography technology to prepare interdigitated structures with a width of 80 microns;

[0028] 3) Metal Thermal Evaporation (PVD): Use a thermal evaporation coater to vaporize metal electrodes Cr / Au (5nm / 20nm) on the substrate to form interdigitated electrodes;

[0029] 4) Preparation of electrospinning liquid: first prepare polyvinyl alcohol into a hydrogel with a concentration of 10% by mass, then disperse the polyaniline / carbon composite m...

Embodiment 2

[0037] There is the preparation method of micro-supercapacitor with high softness and transparency, it comprises the steps:

[0038] 1) Coat the photoresist LOR3A on the PET substrate with a coater at a speed of 4000rpm, and spin coating for 40s, then bake the glue with an electric heating plate at 185°C for 5min, and then coat the photoresist S1805 on the surface at a speed of 40s 4000rpm, spin-coating time is 40s, and then use a hot plate to bake the glue at 115°C for 5min;

[0039] 2) Using ultraviolet lithography technology to prepare interdigitated structures with a width of 80 microns;

[0040] 3) Metal Thermal Evaporation (PVD): Use a thermal evaporation coater to vaporize metal electrodes Cr / Au (5nm / 20nm) on the substrate to form interdigitated electrodes;

[0041] 4) Preparation of electrospinning solution: first prepare polyvinyl alcohol as 10% hydrogel, then disperse polyaniline / carbon composite material in chloroform, stir and disperse for 15 minutes;

[0042] 5)...

Embodiment 3

[0049] There is the preparation method of highly flexible and transparent miniature supercapacitor, it comprises the steps:

[0050] 1) Coat the photoresist LOR3A on the PET substrate with a coater at a speed of 4000rpm, and spin coating for 40s, then bake the glue with an electric heating plate at 185°C for 5min, and then coat the photoresist S1805 on the surface at a speed of 40s 4000rpm, spin-coating time is 40s, and then use a hot plate to bake the glue at 115°C for 5min;

[0051] 2) Using ultraviolet lithography technology to prepare interdigitated structures with a width of 80 microns;

[0052] 3) Metal Thermal Evaporation (PVD): Use a thermal evaporation coater to vaporize metal electrodes Cr / Au (5nm / 20nm) on the substrate to form interdigitated electrodes;

[0053] 4) Preparation of electrospinning solution: first prepare polyvinyl alcohol as 10% hydrogel, then disperse polyaniline / carbon composite material in chloroform, stir and disperse for 15 minutes;

[0054] 5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com