A method for modifying fly ash with simple process

A technology with simple process and fly ash, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor flexural performance and achieve low industrialization cost, reduce brittleness, and respond The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

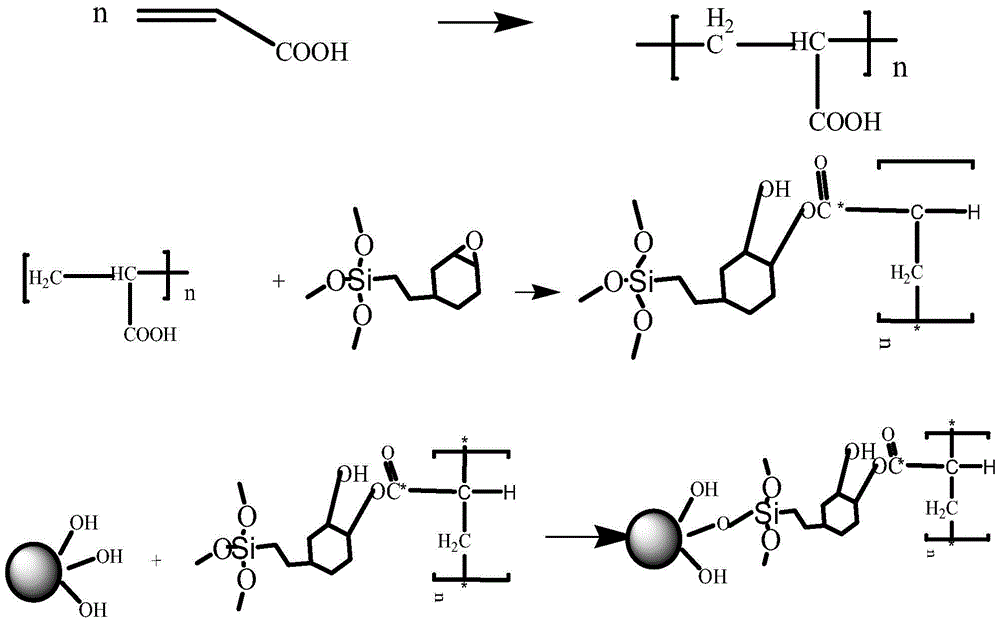

Method used

Image

Examples

Embodiment 1

[0028] 1. Add 100g of fly ash to absolute ethanol, ultrasonically disperse for 30 minutes, then centrifuge, repeat ultrasonically disperse, and centrifuge 3 times; then add distilled water, ultrasonically disperse for 15min, then centrifuge, repeat ultrasonically disperse, centrifuge 3 times, vacuum After drying, the pretreated fly ash is obtained. The purpose of pretreatment is to remove impurities, activate, and disperse the particles of fly ash evenly.

[0029] 2. Slowly pour the pretreated fly ash into a sodium hydroxide solution with a mass concentration of 20%, while continuously stirring and reacting for 24 hours, filter under reduced pressure, wash with distilled water until the pH is 8-9 to obtain alkali-treated fly ash; Pour the alkali-treated fly ash into a sulfuric acid solution with a mass concentration of 10%, continuously stir and react for 4 hours, filter under reduced pressure, wash with distilled water until neutral, and dry in vacuum to obtain hydroxylated f...

Embodiment 2

[0032] 1. Add fly ash to absolute ethanol, ultrasonically disperse for 30 minutes, then centrifuge, repeat ultrasonically disperse and centrifuge 3 times, then add distilled water, ultrasonically disperse for 15 minutes, then centrifuge, repeat ultrasonically disperse, centrifuge 3 times, and vacuum dry Then get the pretreated fly ash. The purpose of pretreatment is to remove impurities, activate, and disperse the particles of fly ash evenly.

[0033] 2. Slowly pour the pretreated fly ash into a sodium hydroxide solution with a mass concentration of 20%, while continuously stirring and reacting for 24 hours, filter under reduced pressure, wash with distilled water until the pH is 8-9 to obtain alkali-treated fly ash; Pour the alkali-treated fly ash into a sulfuric acid solution with a mass concentration of 10%, continuously stir and react for 4 hours, filter under reduced pressure, wash with distilled water until neutral, and dry in vacuum to obtain hydroxylated fly ash.

[0...

Embodiment 3

[0036] 1. Add fly ash to absolute ethanol, ultrasonically disperse for 30 minutes, then centrifuge, repeat ultrasonically disperse and centrifuge 3 times, then add distilled water, ultrasonically disperse for 15 minutes, then centrifuge, repeat ultrasonically disperse, centrifuge 3 times, and vacuum dry Then get the pretreated fly ash. The purpose of pretreatment is to remove impurities, activate, and disperse the particles of fly ash evenly.

[0037]2. Slowly pour the pretreated fly ash into a sodium hydroxide solution with a mass concentration of 20%, while continuously stirring and reacting for 24 hours, filter under reduced pressure, wash with distilled water until the pH is 8-9 to obtain alkali-treated fly ash; Pour the alkali-treated fly ash into a sulfuric acid solution with a mass concentration of 10%, continuously stir and react for 4 hours, filter under reduced pressure, wash with distilled water until neutral, and dry in vacuum to obtain hydroxylated fly ash.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com