Lithium-ion battery precursor material, composite positive electrode material and preparation method thereof

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability, battery safety, explosion, etc., achieve high-voltage cycle stable electrochemical performance, and improve processing performance And the effect of excellent storage performance and physical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

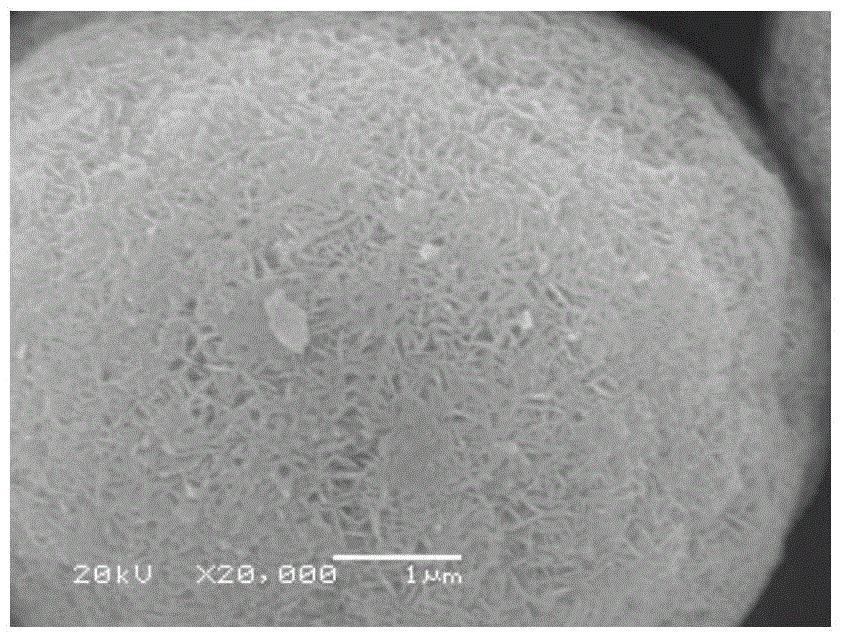

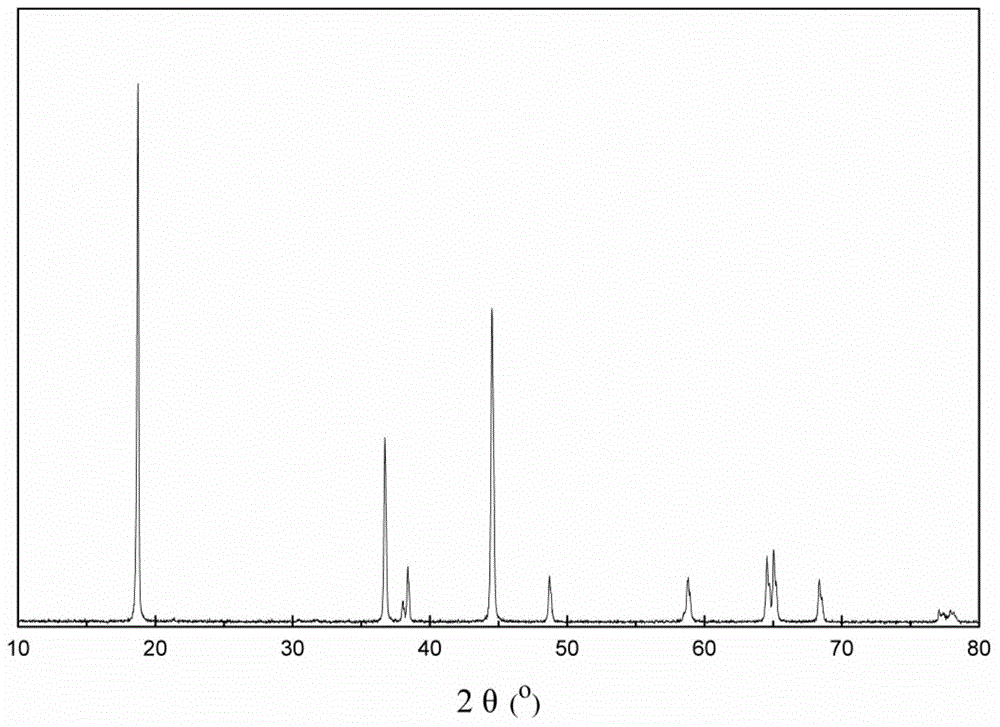

Embodiment 1

[0044] The preparation nickel-cobalt ion concentration is 2mol / L, the nickel-cobalt mixed solution of Ni:Co=80:15, the sodium metaaluminate solution of aluminum content 0.5mol / L (the complex solution of aluminum and hydroxide, press Al 3+ :OH - =1:4 formulated), 4mol / L NaOH solution, 7mol / L ammonia water;

[0045] In the 150L reaction kettle, add ammonia solution as the bottom liquid in advance, the temperature is 50°C, (NH 3 ·H 2 O+NH 4 + ) concentration is 1mol / L, pH is 11.50±0.02, a total of 40L;

[0046] Feed nickel-cobalt mixed solution, sodium metaaluminate solution, NaOH solution and concentrated ammonia water into the reaction kettle separately, and the feeding speeds are: 20±1mL / min, 4.21±0.05mL / min, 20±5mL / min, 7±1mL / min, the reaction temperature is controlled at 50°C, the pH is 11.40-11.50, the stirring speed is 400r / min, and the reaction is stopped when the product particle size distribution D50=11.4-11.5 microns;

[0047] After the materials in the reactor w...

Embodiment 2

[0050] Preparation of nickel-cobalt ion concentration is 2mol / L, Ni:Co=80:10 nickel-cobalt mixed solution, aluminum content 0.5mol / L Al:EDTA=1:1.05 aluminum-containing complex solution, mass concentration 10% NaOH Solution, 0.5mol / l EDTA solution;

[0051] Add the EDTA solution as the bottom liquid in advance in the 150L reactor, the temperature is 50°C, the EDTA concentration is 0.02mol / L, the pH is 11.50±0.02, and the volume is 40L;

[0052] Feed nickel-cobalt mixed solution, aluminum-containing complex solution, NaOH solution and EDTA solution into the reaction kettle at the same time, and the feeding speeds are: 20±1mL / min, 8.89±0.05mL / min, 37±2mL / min , 2.7±0.1mL / min Continuous reaction under the condition of reaction temperature of 50°C, pH of 11.40-11.50, and stirring speed of 400r / min, stop the reaction when the product particle size distribution D50=11.4-11.5 microns;

[0053] After the materials in the reactor were left to stand for 1 hour, the supernatant was draine...

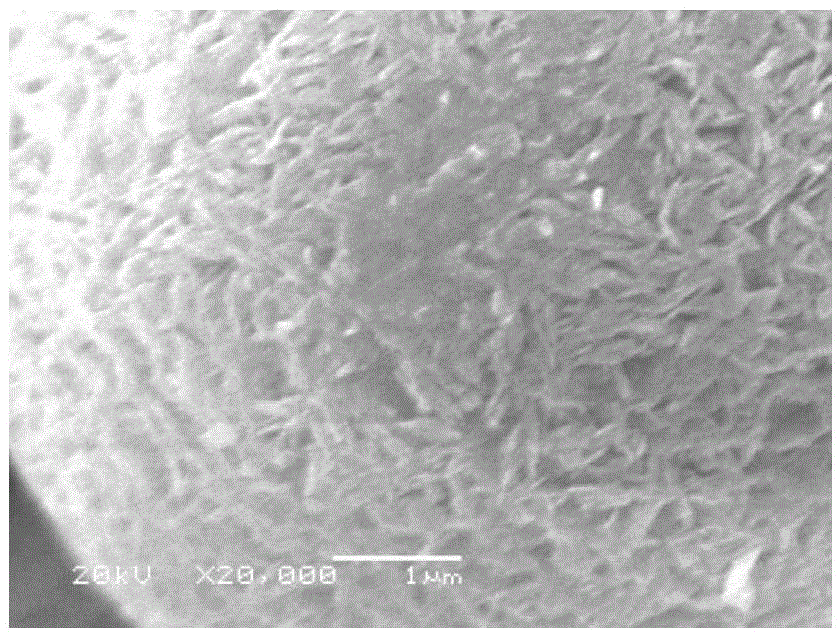

Embodiment 3

[0056] Preparation of nickel-cobalt ion concentration is 2mol / L, Ni:Co=80:15 nickel-cobalt mixed solution, aluminum content 0.5mol / L Al:EDTA=1:1.05 aluminum-containing complex solution, mass concentration 30% NaOH Solution, 7mol / L ammonia water;

[0057] In the 150L reaction kettle, add ammonia solution as the bottom liquid in advance, the temperature is 50°C, (NH 3 ·H 2 O+NH 4 + ) concentration is 1mol / L, pH is 11.50±0.02, volume is 40L;

[0058] Feed nickel-cobalt mixed solution, aluminum-containing complex solution, NaOH solution and concentrated ammonia water into the 150L reaction kettle at the same time. min and 7±1mL / min. The reaction temperature is 50°C, the pH is 11.40-11.50, and the stirring speed is 400r / min. The reaction is continued, and the reaction is stopped when the product particle size distribution D50=11.4-11.5 microns;

[0059] After the materials in the reactor were left to stand for 1 hour, the supernatant was drained away. Use deionized water, 4m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com