Preparation method and application of g-C3N4/CaIn2S4 visible light compound photocatalyst

A C3N4, cain2s4 technology, applied in the direction of light water/sewage treatment, energy wastewater treatment, etc., can solve the problems of inability to effectively absorb visible light, reduce the utilization rate of light energy, and low photocatalytic efficiency, and achieve uniform appearance and low cost , the effect of high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] a g‐C 3 N 4 / CaIn 2 S 4 The preparation method of visible light composite photocatalyst comprises the following steps:

[0033] (1) Add 0.12g of g-C 3 N 4Dissolve the powder in 60ml of deionized water, ultrasonically disperse for 20min, then add 10mmol of calcium nitrate and 20mmol of indium nitrate to obtain a mixed solution, then add 80mmol of thioacetamide to it, and stir for 30min at a speed of 600r / min;

[0034] (2) Transfer the suspension prepared in step (1) to an autoclave, and conduct a hydrothermal reaction at 160° C. for 16 hours. After the reaction, cool naturally to room temperature;

[0035] (3) Centrifuge the product of step (2) at a centrifugal rate of 9000r / min, wash the precipitate obtained after centrifugation with deionized water until neutral, then wash with absolute ethanol for 3 times, and dry at 80°C for 6h , to give 3 wt% g‐C after grinding 3 N 4 / CaIn 2 S 4 Visible light composite photocatalyst.

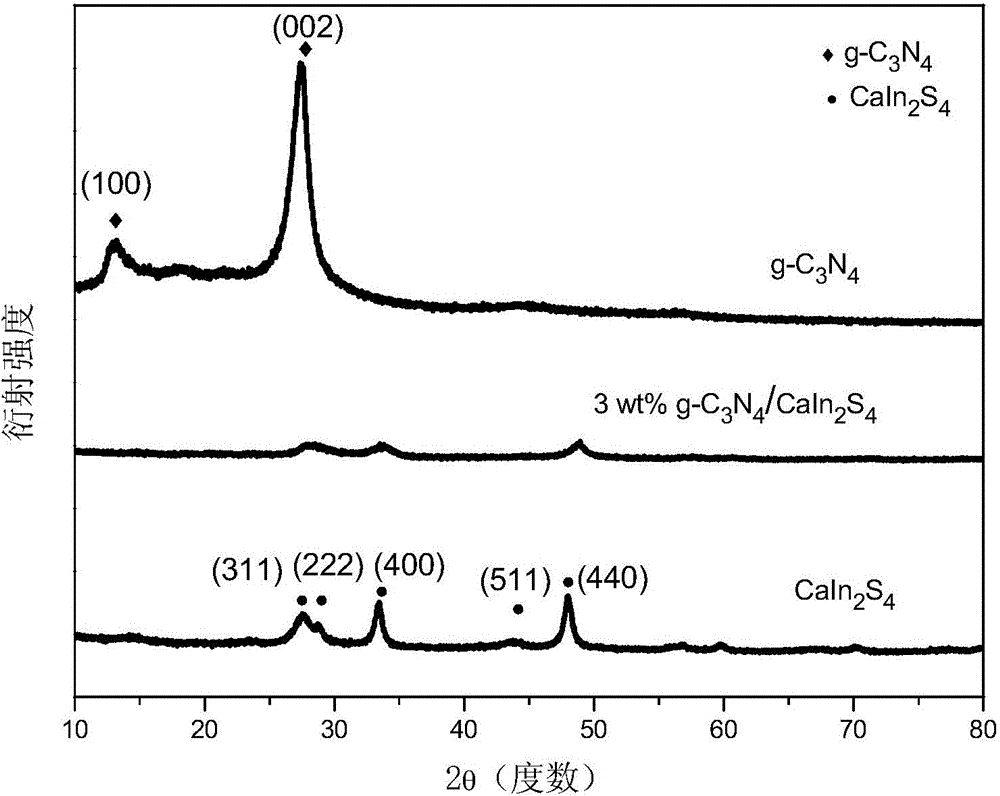

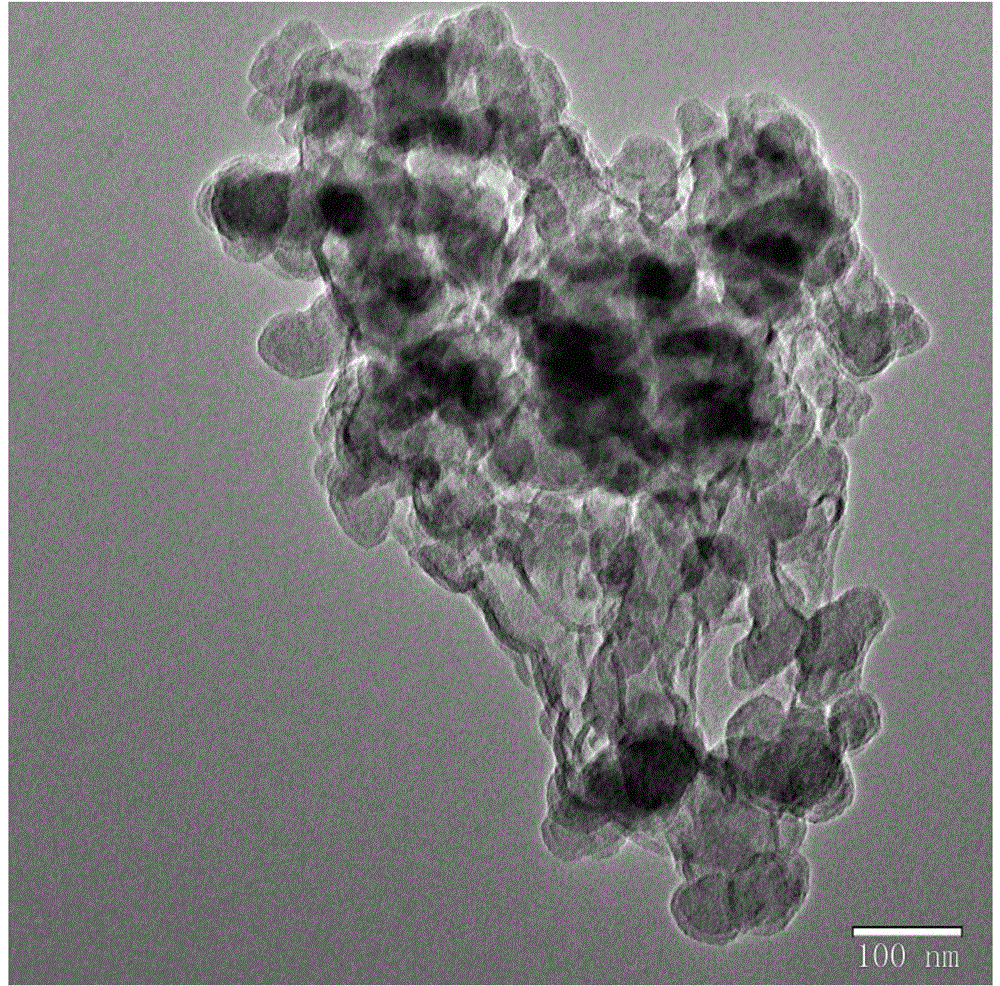

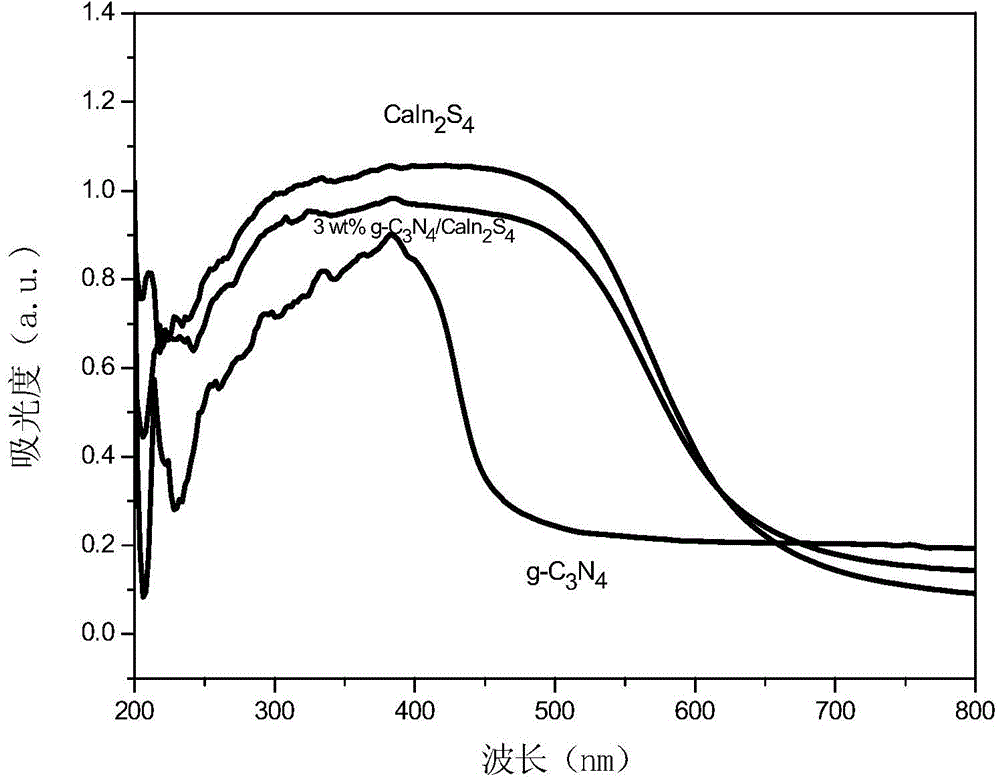

[0036] figure 1 Is the g‐C prepared...

Embodiment 2

[0041] a g‐C 3 N 4 / CaIn 2 S 4 The preparation method of visible light composite photocatalyst comprises the following steps:

[0042] (1) Add 0.1g of g-C 3 N 4 Dissolve the powder in 60ml of deionized water, ultrasonically disperse for 20min, then add 5mmol of calcium nitrate and 10mmol of indium nitrate to obtain a mixed solution, stir evenly, then add 40mmol of thioacetamide to it, stir for 30min, and rotate at a speed of 500r / min;

[0043] (2) Transfer the suspension prepared in step (1) to an autoclave, and conduct a hydrothermal reaction at 120° C. for 24 hours. After the reaction, cool naturally to room temperature;

[0044] (3) Centrifuge the product of step (2) at a centrifugal rate of 9000r / min, wash the precipitate obtained after centrifugation with deionized water until neutral, then wash with absolute ethanol 3 times, and dry at 90°C for 4h , to give 5 wt% g‐C after grinding 3 N 4 / CaIn 2 S 4 Visible light composite photocatalyst.

[0045] g-C in this e...

Embodiment 3

[0047] (1) Add 0.14g of g-C 3 N 4 Dissolve the powder in 60ml of deionized water, ultrasonically disperse for 20min, then add 5mmol of calcium nitrate and 10mmol of indium nitrate to obtain a mixed solution, stir evenly, then add 40mmol of thioacetamide to it, stir for 30min, and rotate at 600r / min;

[0048] (2) Transfer the suspension prepared in step (1) to an autoclave, and conduct a hydrothermal reaction at 160° C. for 16 hours. After the reaction, cool naturally to room temperature;

[0049] (3) Centrifuge the product of step (2) at a centrifugal rate of 8500r / min, wash the precipitate obtained after centrifugation with deionized water until neutral, then wash with absolute ethanol 3 times, and dry at 90°C for 4h , 7 wt% g‐C was obtained after grinding 3 N 4 / CaIn 2 S 4 Visible light composite photocatalyst.

[0050] g-C in this example 3 N 4 / CaIn 2 S 4 X-ray diffraction pattern, transmission electron microscope pattern, N 2 The adsorption isotherm curves and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com