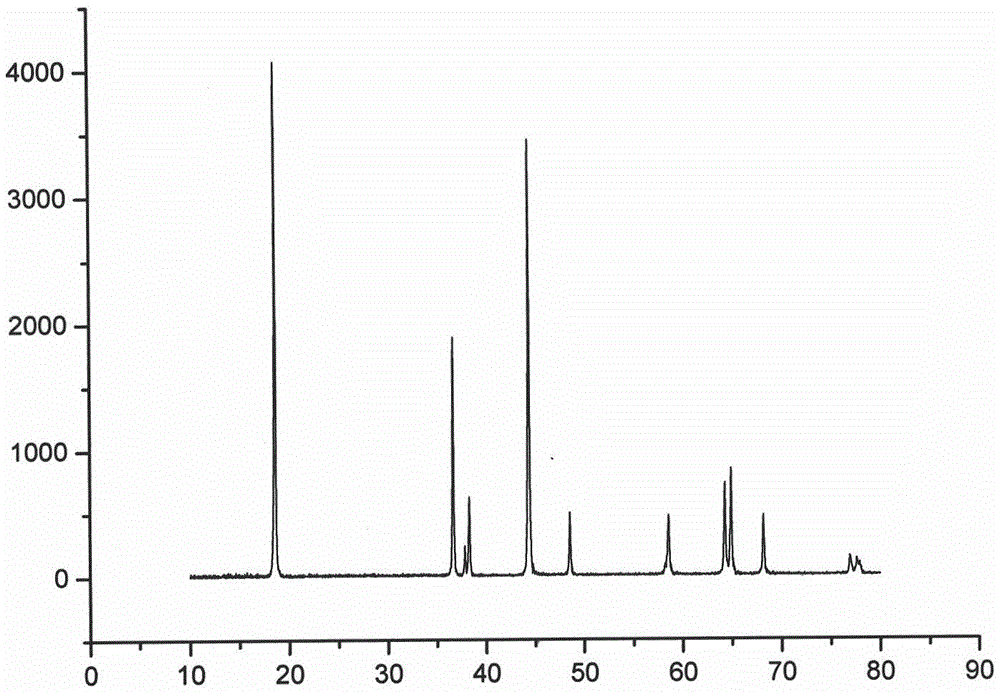

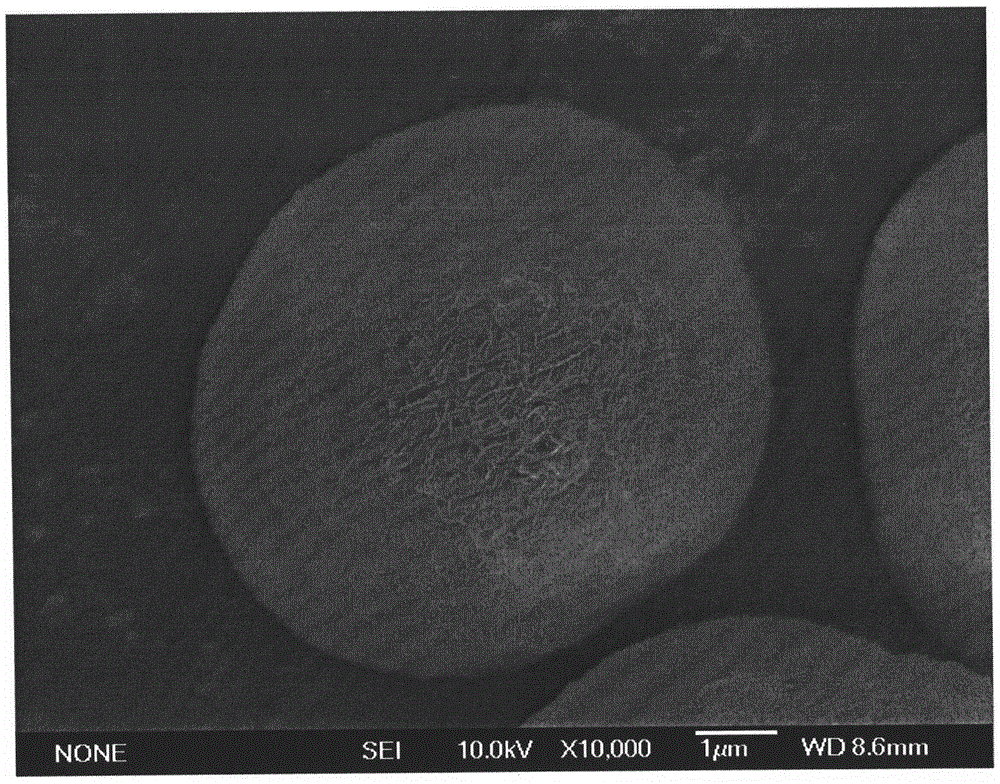

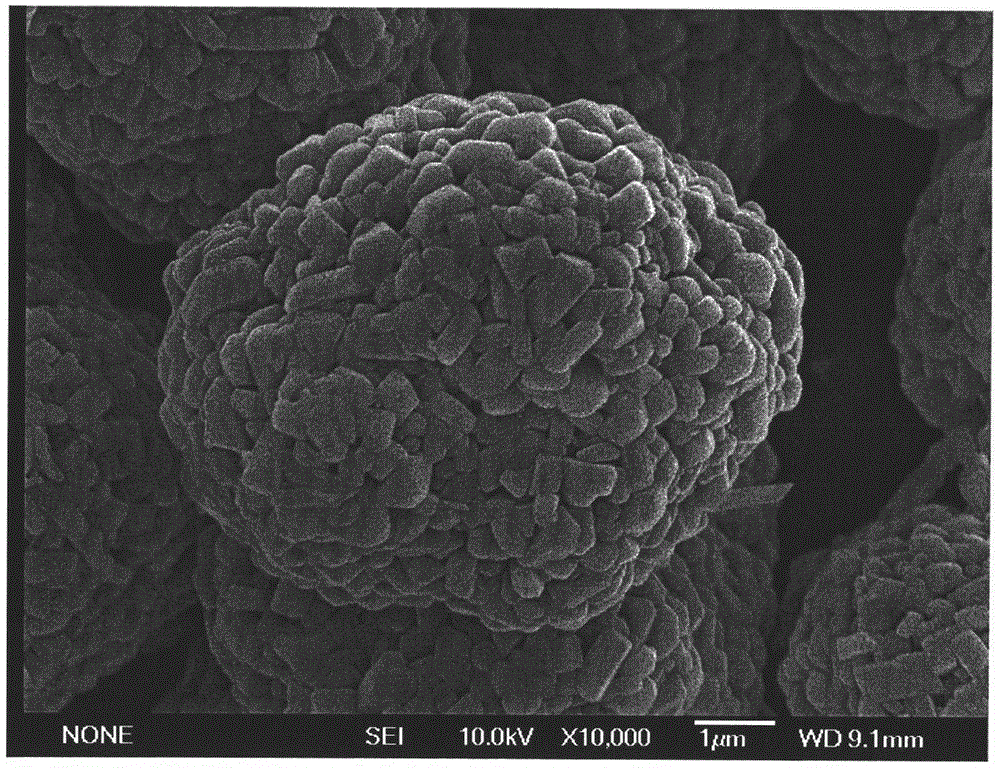

Preparation method of core-shell-structure nickel cobalt lithium aluminate

A technology of nickel cobalt lithium aluminate, core-shell structure, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as difficult to fully exert performance, complex process, poor performance, etc., to improve cycle stability and thermal stability. performance, the process is simple and easy, and the effect of reducing nickel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Prepare 8L total molar concentration of 2M nickel-cobalt salt solution A, wherein Ni:Co=9:1, as the salt solution for preparing the core material; prepare 4L total molar concentration of 2M salt containing nickel salt, cobalt salt, aluminum salt Solution B, wherein Ni: Co: Al = 6: 2.5: 1.5 is used as the salt solution for preparing the shell material, and 8 L of sodium hydroxide solution with a concentration of 2 M is prepared, and ammonia water is added to mix evenly so that the ammonia concentration in the mixed solution is 4 M as an alkaline solution C; Prepare 4L of sodium carbonate solution with a concentration of 2M, add ammonia water and mix evenly so that the ammonia concentration in the mixed solution is 4M as alkaline solution D.

[0021] Inject the prepared salt solution A into the reaction kettle with bottom liquid at a constant speed of 0.4L / h, and at the same time, add alkali solution C to adjust the pH value of the solution in the reaction kettle between 1...

Embodiment 2

[0024] Prepare 4L total molar concentration of 2M solution A containing nickel-cobalt-aluminum salt, wherein Ni:Co:Al=9:0.5:0.5, as the salt solution for preparing the core material; prepare 8L total molar concentration of 2M containing nickel salt, cobalt salt , the salt solution B of aluminum salt, wherein Ni: Co: Al=6: 1.25: 2.75 is used as the salt solution for preparing the shell material, prepares 4L of sodium hydroxide solution with a concentration of 2M, adds ammonia water and mixes to make the ammonia concentration in the mixed solution 4M as alkaline solution C; prepare 8L of sodium carbonate solution with a concentration of 2M, add ammonia water and mix well so that the ammonia concentration in the mixed solution is 4M as alkaline solution D.

[0025] Inject the prepared salt solution A into the reaction kettle with bottom liquid at a constant speed of 0.6L / h. At the same time, add alkali solution C to adjust the pH value of the solution in the reaction kettle betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com