Method for treating and recycling process waste water generated during production of 1,2-Benzisothiazolin-3-One

A technology for benzisothiazole and production process is applied in the field of treatment and resource utilization of 1,2-benzisothiazol-3-one production process wastewater, which can solve the problems of waste, high treatment cost and high energy consumption, and achieves the Achieving the effect of recycling waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

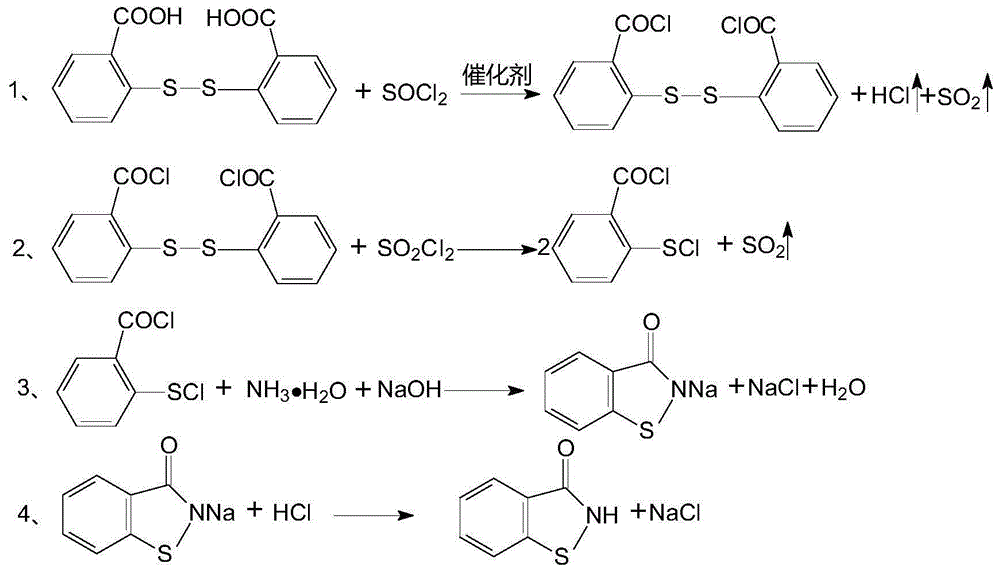

Method used

Image

Examples

Embodiment 1

[0018] Pack 20mL of NDA150 resin with a dry weight of about 15g into two adsorption columns (Φ20×250mm) in the first adsorption column and the second adsorption column with insulation jackets.

[0019] Take 1000mL of reddish-brown 1,2-benzisothiazol-3-one production process wastewater and filter, add 0.5ml of 1% liquid caustic soda dropwise, and put the column liquid COD Cr 23420mg / L, 1,2-benzisothiazol-3-one content is 6240mg / L, at 35±5℃, 400ml upper column solution is passed through the NDA150 resin column at a flow rate of 40mL / h, and the primary effluent is yellow. The water output from the second adsorption column is light yellow, and the content of 1,2-benzisothiazol-3-one in the secondary adsorption water is 222.6mg / L, COD Cr Reduced to 1292mg / L, the water is distilled to recover 44.6g of crude sodium chloride salt after drying, and the effluent can reach the national first-class discharge standard after aerobic biochemical treatment.

[0020] The adsorbed NDA150 resin...

Embodiment 2

[0022] Pack 300mL of ZH124 resin with a dry weight of about 225g into two first and second adsorption columns (Φ35×500mm) with insulation jackets respectively.

[0023] Take 10L of reddish-brown 1,2-benzisothiazol-3-one production process wastewater and filter it, add 5ml of 1% liquid alkali dropwise, and put the column liquid COD Cr The content of 1,2-benzisothiazol-3-one is 6117mg / L. At 5±5℃, 6600ml of the upper column liquid is passed through the ZH124 resin column at a flow rate of 300mL / h, and the primary effluent is yellow. The water output from the second adsorption column is light yellow, and the content of 1,2-benzisothiazol-3-one in the secondary adsorption water is 116.8g / L, COD Cr Reduced to 1067mg / L, the water is distilled to recover 694.8g of crude sodium chloride salt after drying, and the effluent can reach the national first-level discharge standard after aerobic biochemical treatment.

[0024] The adsorbed ZH124 resin is desorbed and regenerated with 900mL o...

Embodiment 3

[0026] The adsorbents in Examples 1 and 2 in Examples 1 and 2 were changed to FZH11, ZH01, ZH33, JX101, CHA111 resins and American AmberLiteXAD-4, XAD-2, XAD-7 resins respectively, and other operating conditions remained unchanged , the results are basically the same except that the volume of each batch and the amount of recovery are changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com