Wear-resistant composite material

A technology of composite materials and composites, which is applied in the field of new composite materials, can solve problems such as difficulty in creating brand product benefits, insufficient technical research and innovation strength, widening gap, etc., achieve good curing effect, meet development and application, and avoid The effect of wear failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] React 100g of bisphenol A type cyanate monomer with 10g of vinyl monomer at 125°C for 45 minutes to obtain a heat-resistant resin prepolymer; the structural formula of vinyl monomer is .

[0032] 200g of epoxy resin and 80g of succinic anhydride were reacted at 130°C for 60 minutes to obtain a high-viscosity resin prepolymer. The epoxy resins used in Examples 1 to 5 are o-cresol novolac epoxy resins, phenol novolac epoxy resins, bisphenol A formaldehyde novolac epoxy resins, biphenyl epoxy resins, and triphenol hydroxymethane novolac epoxy resins.

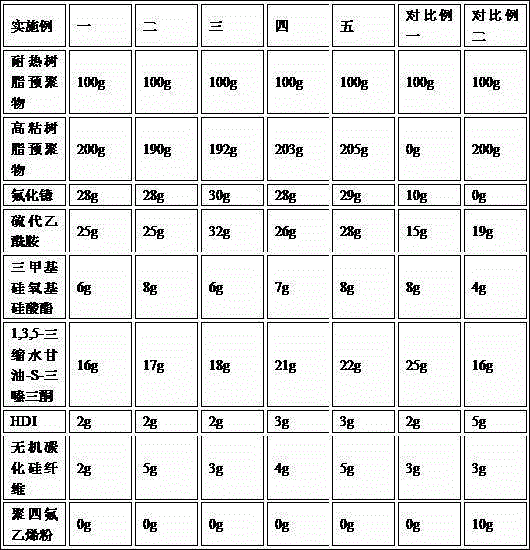

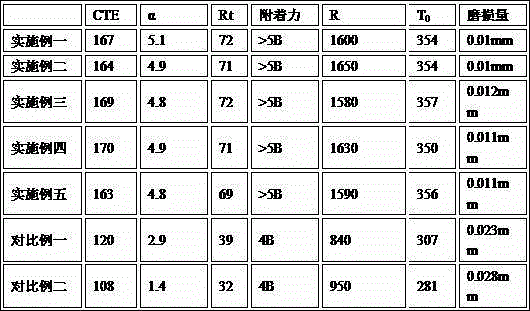

[0033] According to the mass composition in Table 1, mix ytterbium fluoride, thioacetamide, and trimethylsiloxysilicate evenly to obtain a mixture; sequentially mix 1,3,5-triglycidyl-S-triazinetrione 1. Add inorganic fiber into the mixture, stir for 4 hours, then add isocyanate curing agent, stir at 60°C for 2 hours; finally add heat-resistant resin prepolymer, high-viscosity resin prepolymer, stir at 120°C for 6 hours, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com