Silica-based perovskite heterojunction solar cell and preparation method thereof

A silicon-based perovskite, solar cell technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high-risk chemicals of raw materials, expensive equipment, etc., to achieve superior electrical and optical performance, full utilization, avoidance The effect of high temperature treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

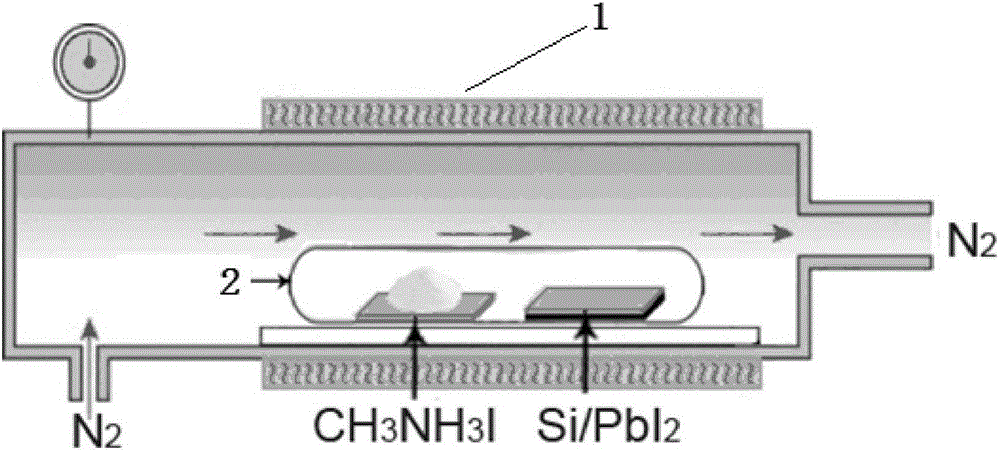

Method used

Image

Examples

Embodiment 1

[0042] Such as Figure 7 As shown in , the silicon-based perovskite heterojunction solar cell provided in this embodiment, the structure of the solar cell from top to bottom is: aluminum electrode, gold conductive film, perovskite, alumina, n-type silicon wafer and Silver electrode with perovskite as CH 3 NH 3 PB 3 .

[0043] The silicon-based perovskite heterojunction solar cell is prepared as follows:

[0044] (1) RCA cleaning process is used to clean the n-type silicon wafer, and then use N 2 Blow dry the silicon wafer;

[0045] The RCA cleaning process is as follows:

[0046] ①Immerse the silicon wafer in 20wt% KOH solution for 3min, keep the solution temperature at 80°C, and then wash it with deionized water;

[0047] ②Immerse the wafer in concentrated H 2 SO 4 and H 2 o 2 (vol%=3:1) mixed solution for 30min, where H 2 o 2 The concentration was 58%, and then washed with deionized water;

[0048] ③ Then immerse in 10% HF solution for 2 minutes, and then wash ...

Embodiment 2

[0065] Such as Figure 7 As shown in , the silicon-based perovskite heterojunction solar cell provided in this embodiment, the structure of the solar cell from top to bottom is: aluminum electrode, gold conductive film, perovskite, alumina, n-type silicon wafer and Silver electrode with perovskite as CH 3 NH 3 PB 3 .

[0066] The silicon-based perovskite heterojunction solar cell is prepared as follows:

[0067] (1) RCA cleaning process is used to clean the silicon wafer, and then use N 2 Blow dry the silicon wafer;

[0068] (2) Using atomic layer deposition (ALD) technology, set the deposition temperature to 180°C, Al(TMA), N 2、H 2 The pulse time of O is: 0.1s, 10s and 0.1s, respectively, the flow rate is: 140sccm, 140sccm and 195sccm, respectively, and 30 cycles are performed to deposit 3nm Al on the surface of the silicon wafer. 2 o 3 ;

[0069] (3) Then use a resistance evaporation coating machine, set the substrate temperature to 28°C, and the vacuum degree to 5...

Embodiment 3

[0074] Such as Figure 7 As shown in , the silicon-based perovskite heterojunction solar cell provided in this embodiment, the structure of the solar cell from top to bottom is: aluminum electrode, gold conductive film, perovskite, alumina, n-type silicon wafer and Silver electrode with perovskite as CH 3 NH 3 PB 3 .

[0075] The silicon-based perovskite heterojunction solar cell is prepared as follows:

[0076] (1) RCA cleaning process is used to clean the silicon wafer, and then use N 2 Blow dry the silicon wafer;

[0077] (2) Using atomic layer deposition (ALD) technology, set the deposition temperature to 220°C, Al(TMA), N 2 、H 2 The pulse time of O is: 0.1s, 10s and 0.1s, the flow rates are: 155sccm, 155sccm and 205sccm, respectively, and 50 cycles are performed to deposit 5nm Al on the surface of the silicon wafer. 2 o 3 ;

[0078] (3) Then use a resistance evaporation coating machine, set the substrate temperature to 30°C, and the vacuum degree to 8×10 -4 Pa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com