Preparation method for compound iron-zinc coagulant

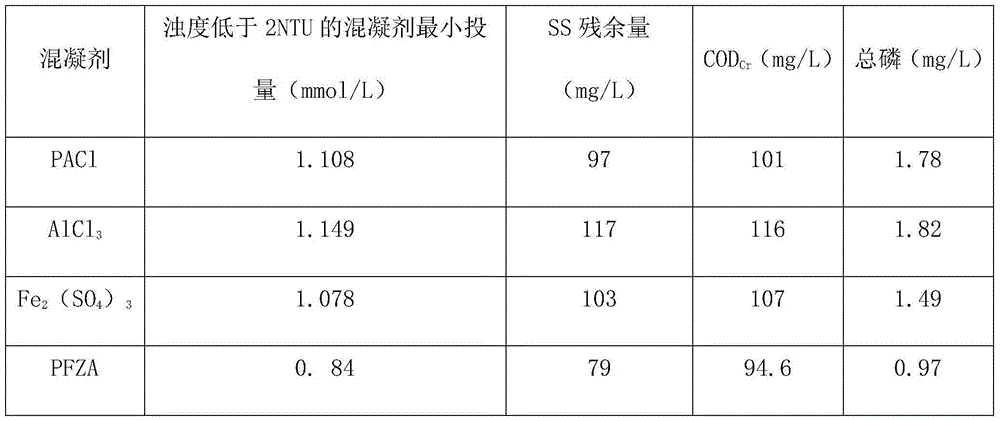

An iron-zinc coagulant and a technology for polymerizing iron, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of lack of competitiveness in effect and cost, and achieve the effect of good coagulation effect, fast speed and less residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 0.2mol / L ferrous sulfate solution, 0.2mol / L aluminum sulfate solution, after mixing according to the volume ratio of 1:5, add an appropriate amount of 0.2mol / L NaOH solution to alkalinize it to pH 2.1; take the above mixed The solution was microwaved for 15 minutes under the condition of feeding oxygen prepared by an oxygen generator, the microwave frequency was 2450MHz, the power was 900W, and aged for 24 hours to make a polymerized iron / aluminum composite colloid, which was in a brownish red stable and transparent state at this time; take 200mL of the above Add 10mL of 0.1mol / L zinc chloride solution to the polymerized iron / aluminum composite colloid after microwave treatment, add 10mL of 0.5% polydimethyldiallylammonium chloride solution, and stir for 30min to form a composite Iron zinc coagulant (PFZA).

Embodiment 2

[0021] 0.3mol / L ferrous chloride solution, 0.3mol / L aluminum chloride solution, after mixing according to the ratio of 1:1 by volume, add an appropriate amount of 0.2mol / L KOH solution to alkalize it to pH 1.8; take The above-mentioned mixed solution was microwaved for 30 minutes under the condition of introducing air depleted of carbon dioxide, microwave frequency 2450MHz, power 900W, and aged for 12 hours to make a polymerized iron / aluminum composite colloid, which was in a brownish red stable and transparent state at this time; take 200mL of the above Add 4mL of 0.1mol / L zinc chloride solution to the polymerized iron / aluminum composite colloid after microwave treatment, add 4mL of 0.5% polydimethyldiallyl ammonium chloride solution, and stir for 30min to prepare into a composite iron-zinc coagulant (PFZA).

Embodiment 3

[0023] 0.1mol / L ferrous chloride solution, 0.1mol / L aluminum chloride solution, after mixing according to the volume ratio of 1:10, add an appropriate amount of 0.2mol / L sodium carbonate solution to alkalinize it to pH 2.3; Take the above-mentioned mixed solution and microwave it for 60 minutes under the condition of introducing the air depleted of carbon dioxide, the microwave frequency is 2450MHz, the power is 900W, and aging for 24 hours to make the polymerized iron / aluminum composite colloid, which is in a brownish red stable and transparent state; take 200mL Add 20mL of 0.1mol / L zinc chloride solution to the above-mentioned polymerized iron / aluminum composite colloid after microwave treatment, add 20mL of 0.5% polydimethyldiallylammonium chloride solution in mass fraction, and stir for 30min, namely Made of composite iron-zinc coagulant (PFZA).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com