Soil improvement material and preparation method thereof

A soil improvement and bentonite technology, applied in the field of green and environmentally friendly soil improvement materials and their preparation, can solve problems such as poor health, secondary pollution, and residues, and achieve the effects of enhancing adsorption performance, reducing emissions, and weakening diffusion and leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of a soil improving material, comprising the steps of:

[0026] Step 1, preparation of rice straw biochar:

[0027] Step A, cutting the rice stalks into small sections of about 5 cm;

[0028] Step B, put the small section of rice straw from step A into a carbonization furnace for carbonization treatment, the carbonization time is 1 hour, and the carbonization temperature is 400 degrees Celsius to produce rice straw biochar;

[0029] Step C, cooling the baked biochar, and sealing and packaging the cooled finished product.

[0030] In order to effectively reduce the emission of greenhouse gases and harmful gases, in the process of preparing rice straw biochar, the step B also includes a flue gas treatment step, and the flue gas treatment step includes setting There is a water cooling device, and the smoke exhaust pipe is connected with the sealed barrel, and the cooled smoke and tar are trapped in the sealed barrel.

[0031] A tail gas purification...

example 1

[0044] Example 1 and its effects:

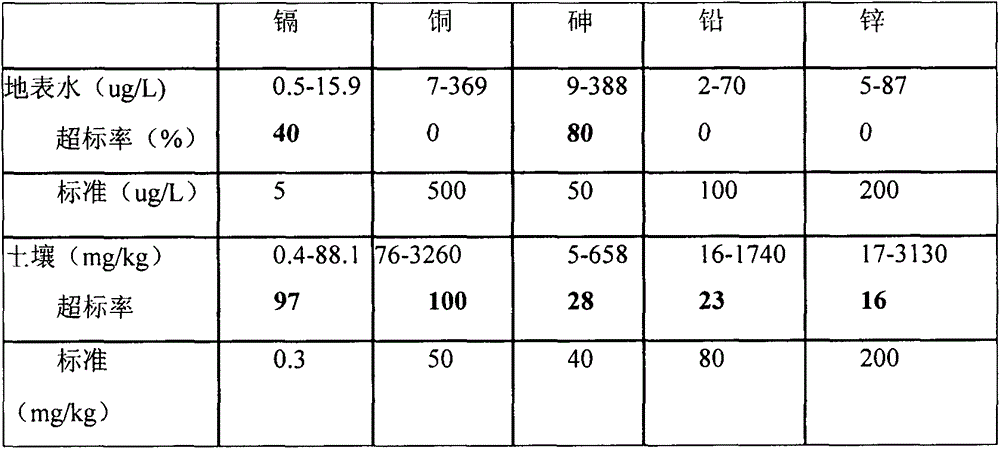

[0045] In 2010, a 1,000-mu heavy metal-exceeding rice field near a mining area in Jiangxi Province was used as the experimental base. The original heavy metal cadmium and lead pollution of the experimental cultivated land was serious.

[0046]

[0047]

[0048] The area of the experimental base is 1000 mu, and soil samples are randomly collected, and a control group and an experimental group are set up. Use the improved material and technical method of this patent to improve the cultivated land soil, apply 300 kg of improved material per mu each time, once every two months, and measure the cadmium and lead content in the soil after 12 months. The results show that: the improved soil The removal rate of cadmium in medium reaches 85%, and the removal rate of Cd reaches 65.9%. The improvement effect is very obvious.

example 2

[0049] Example 2 and its effects:

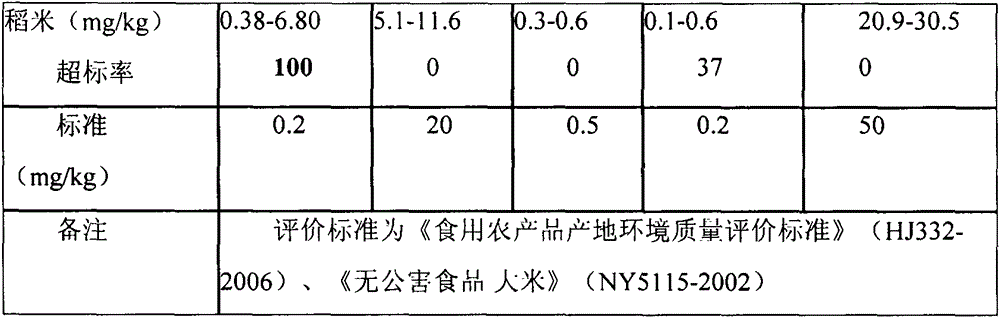

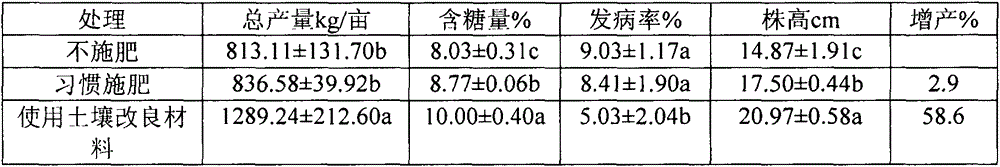

[0050] In Jurong, Jiangsu Province, rice straw bio-carbon-based soil improvement materials were used for 300 mu of strawberry fields, and 100 kg of improved materials were applied per mu per season. The test showed that the incidence of strawberry Verticillium wilt dropped from more than 60% to about 10%, improving strawberry The output is more than 30%, the amount of chemical fertilizer is reduced by 15-30%, and the quality of strawberries is significantly improved, with a net increase of 3000-5000 yuan / mu.

[0051] Effects on yield and growth of continuous cropping strawberry (Jurong, 2013)

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com