Solid dispersion prepared from magnolol, honokiol or mixture of magnolol and honokiol and preparation method of solid dispersion by hot-melt extrusion

A solid dispersion and honokiol technology, which is applied in the direction of active ingredients of hydroxyl compounds, medical preparations of non-active ingredients, antipyretics, etc., can solve the problems of unstable preparations and inability to apply to industrialized large-scale production, and achieve increased Dissolution, bioavailability improvement, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

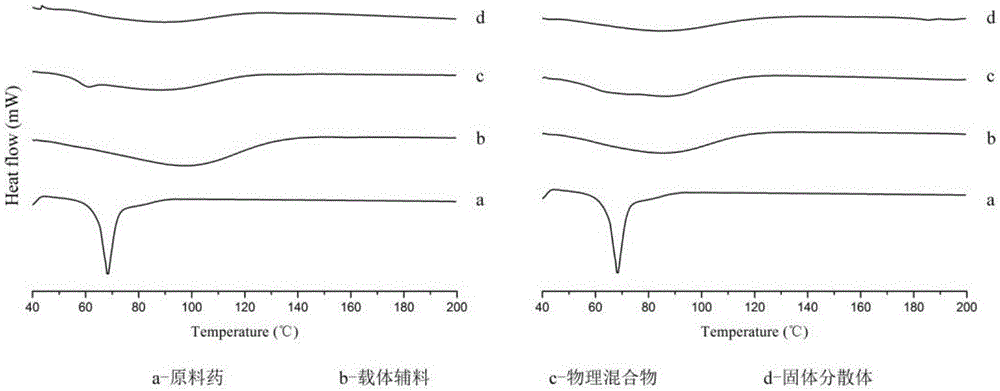

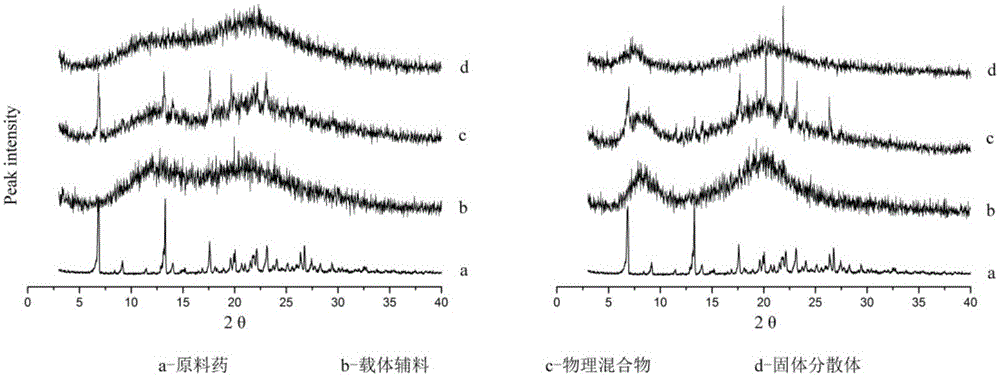

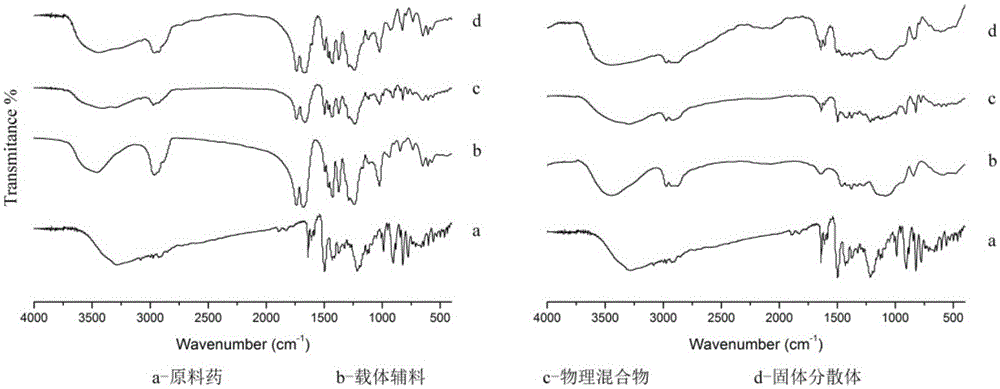

[0019] Magnolol (1%), xylitol (10%), copovidone S-630 (89%) are mixed homogeneously, cross 60 mesh sieves, be prepared into physical mixture, the extrusion temperature of twin-screw extruder is set At 90°C, after the temperature rises to the set value and stabilizes, slowly increase the rotation speed to 50rpm, add the physical mixture at a constant speed to obtain a strip-shaped extrudate, cool, and pulverize through a 20-mesh sieve to obtain a magnolol solid dispersion powder.

Embodiment 2

[0021] Magnolol (20%), xylitol (20%), copovidone S-630 (60%) are mixed homogeneously, cross 80 mesh sieves, be prepared into physical mixture, the extrusion temperature of twin-screw extruder is set At 90°C, after the temperature rises to the set value and stabilizes, slowly increase the rotation speed to 50rpm, add the physical mixture at a constant speed to obtain a strip-shaped extrudate, cool, and crush through a 100-mesh sieve to obtain a magnolol solid dispersion powder.

Embodiment 3

[0023] Honokiol (50%), mannitol (10%), polyethylene caprolactam-polyvinyl acetate-polyethylene glycol graft copolymer (40%) are mixed homogeneously, cross 100 mesh sieves, be prepared into physical mixture , set the extrusion temperature of the twin-screw extruder at 90°C. After the temperature rises to the set value and stabilizes, slowly increase the speed to 50rpm, add the physical mixture at a uniform speed, and obtain a strip-shaped extrudate, cool it, and crush it through 60 mesh Sieve to obtain magnolol solid dispersion powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com