A kind of preparation method of netilmicin sulfate freeze-dried powder injection

A technology of netilmicin sulfate and freeze-dried powder injection, which is applied in the field of preparation of netilmicin sulfate freeze-dried powder injection, can solve the problems of reducing the content of active ingredients, unfavorable practical operation, strict control conditions, etc. High content, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

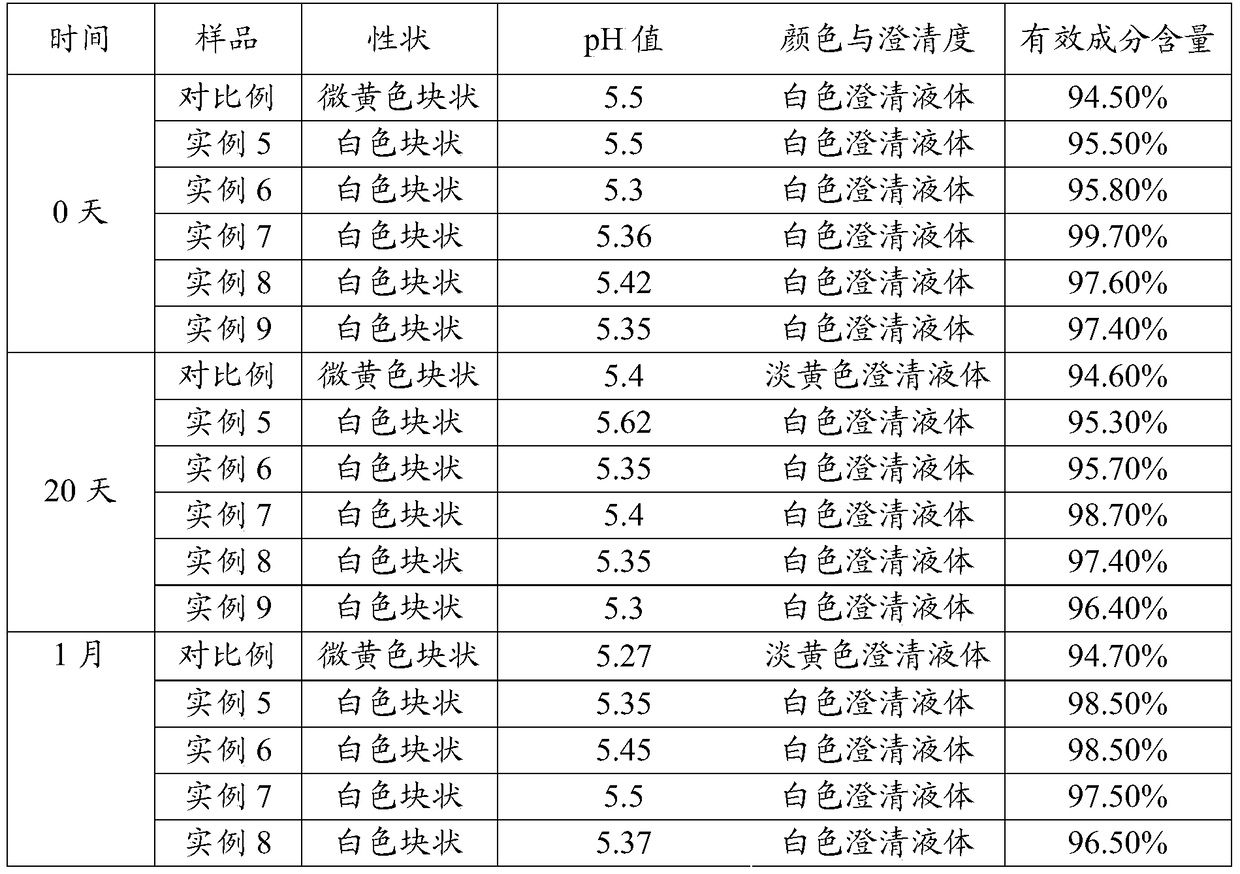

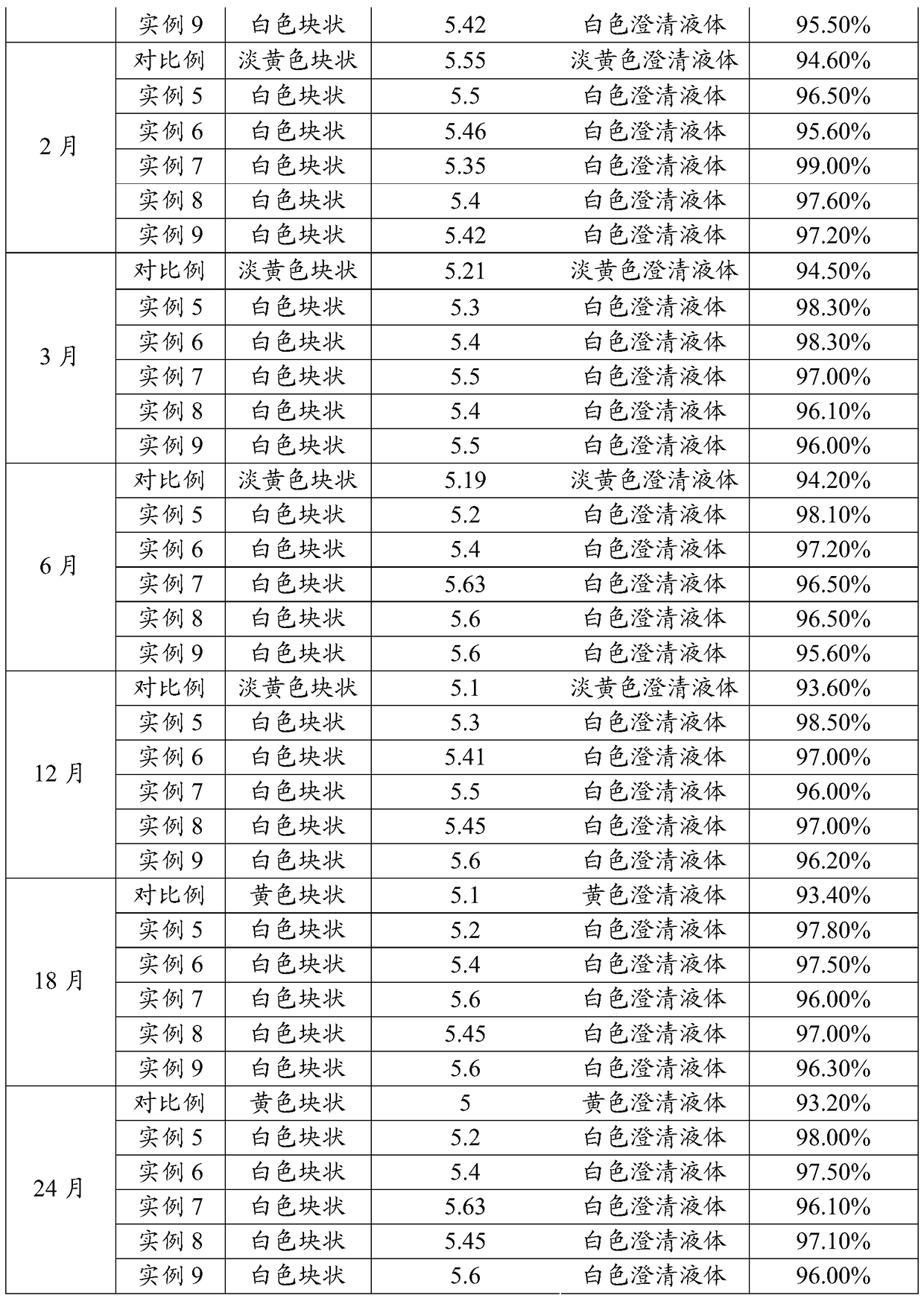

Examples

preparation example Construction

[0034] The invention provides a preparation method of netilmicin sulfate freeze-dried powder injection, comprising the following steps:

[0035] a) mixing netilmicin sulfate, antioxidants, excipients and the first water for injection, followed by pH adjustment and adsorption treatment, to obtain mixed solution A;

[0036] b) mixing the mixed solution A with the second water for injection, followed by freezing treatment and drying treatment, to obtain netilmicin sulfate freeze-dried powder injection;

[0037] The mass ratio of the first water for injection to the second water for injection is 8:(1-3).

[0038] In the present invention, netilmicin sulfate, antioxidant, excipient and the first water for injection are mixed; described netilmicin sulfate is main agent, and the present invention does not have to the source of described netilmicin sulfate For special restrictions, commercially available products well known to those skilled in the art can be used.

[0039] In the pr...

Embodiment 1

[0060] Prepare 1000 sticks of netilmicin sulfate freeze-dried powder injections whose specification is 0.1g / support:

[0061] (1) First add 1.5g sodium thiosulfate to 2400g water for injection, fully dissolve at 10°C, keep the temperature constant, then add 100g netilmicin sulfate and 180g mannitol, stir to dissolve, and then add 1mol / L The sodium hydroxide solution was used to adjust the pH to 5.3, and finally 6.7 g of activated carbon was added and stirred for 15 minutes, and then the titanium rod was decarbonized to obtain a mixed solution A, which was a white clear liquid.

[0062] (2) After mixing the above-mentioned mixed solution A with 600g of water for injection, put it in a vacuum freeze-drying box, first freeze it at -40°C for the first time, then heat it up to -30°C, keep it warm for 40min, and then freeze it at -40°C Freeze for the second time at ℃ to obtain a frozen solid; vacuumize until the vacuum degree is less than or equal to 0.15mbar and then dry, and heat ...

Embodiment 2

[0069] Prepare 1000 sticks of netilmicin sulfate freeze-dried powder injections whose specification is 0.1g / support:

[0070] (1) First, add 0.75g of sodium bisulfite to 2400g of water for injection, fully dissolve at 10°C, keep the temperature constant, then add 100g of netilmicin sulfate and 180g of mannitol, stir to dissolve, and then use 1mol / L The sodium hydroxide solution was used to adjust the pH to 5.3, and finally 6.7 g of activated carbon was added and stirred for 15 minutes, and then the titanium rod was decarbonized to obtain a mixed solution A, which was a white clear liquid.

[0071] (2) After mixing the above-mentioned mixed solution A with 600g of water for injection, put it in a vacuum freeze-drying box, first freeze it at -40°C for the first time, then heat it up to -30°C, keep it warm for 40min, and then freeze it at -40°C Freeze for the second time at ℃ to obtain a frozen solid; vacuumize until the vacuum degree is less than or equal to 0.15mbar and then dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com