Mono-dispersed Pd-Pt nano-catalyst and preparation method therefor

A nanocatalyst, monodisperse technology, applied in chemical instruments and methods, physical/chemical process catalysts, nanotechnology for materials and surface science, etc., can solve problems such as reducing catalytic activity, improve catalytic performance, improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

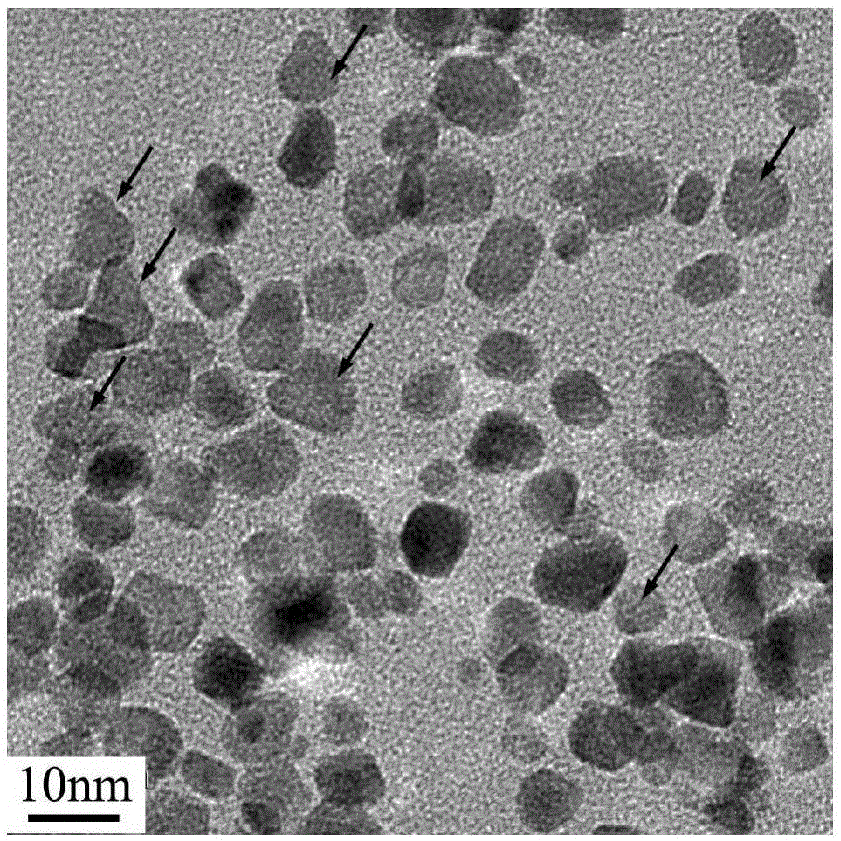

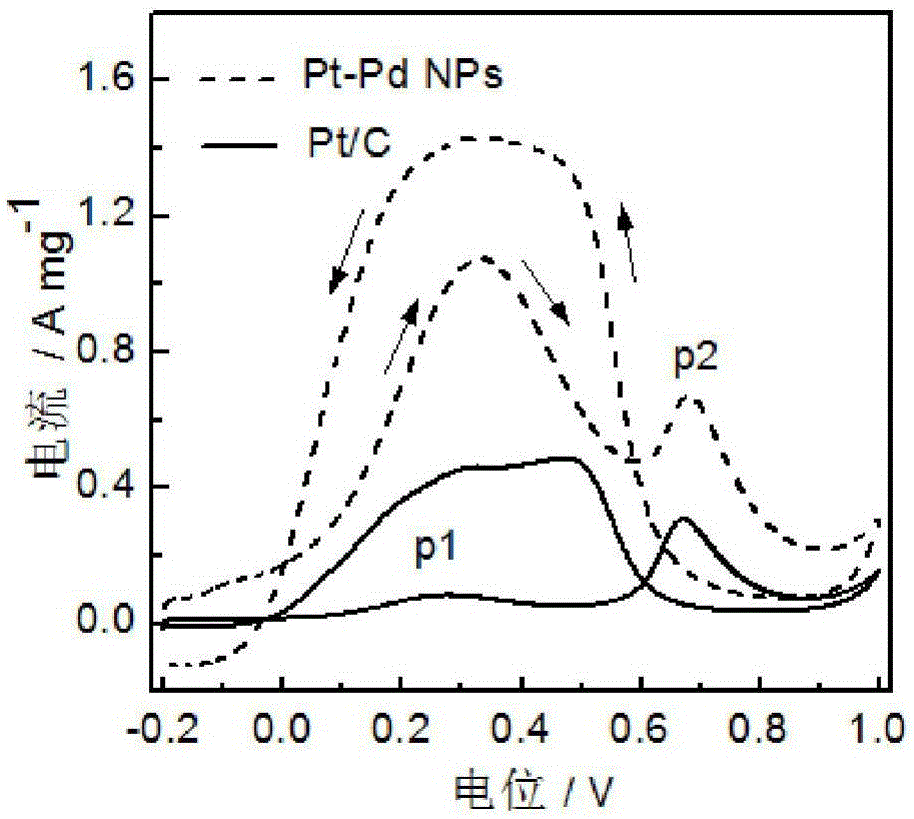

[0032] Embodiment 1, the preparation of monodisperse Pt1Pd1 nanoparticle

[0033]Dissolve chloroplatinic acid and palladium chloride (the molar ratio of platinum to palladium is 1:1) in the mixed solution of formaldehyde and water (the volume ratio of formaldehyde and water is 1:1); Semisiloxane (the molar ratio of metal precursor to octaamic acid silsesquioxane is 1:1), use 5mol / L sodium hydroxide solution to adjust the pH value of the above mixed solution to 11 after ultrasonic oscillation, keep stirring The stabilizer is fully contacted and complexed with Pd ions and Pt ions to obtain an active metal precursor mixed solution; the prepared raw material solution is transferred to a hydrothermal reaction kettle, the reaction temperature is 180 ° C, and the reaction time is 6 h; the reduced The product was centrifugally washed with ultrapure water several times, and then dried in a vacuum dryer (60° C.), and the obtained solid product was uniformly dispersed Pt-Pd nano-catalyst...

Embodiment 2

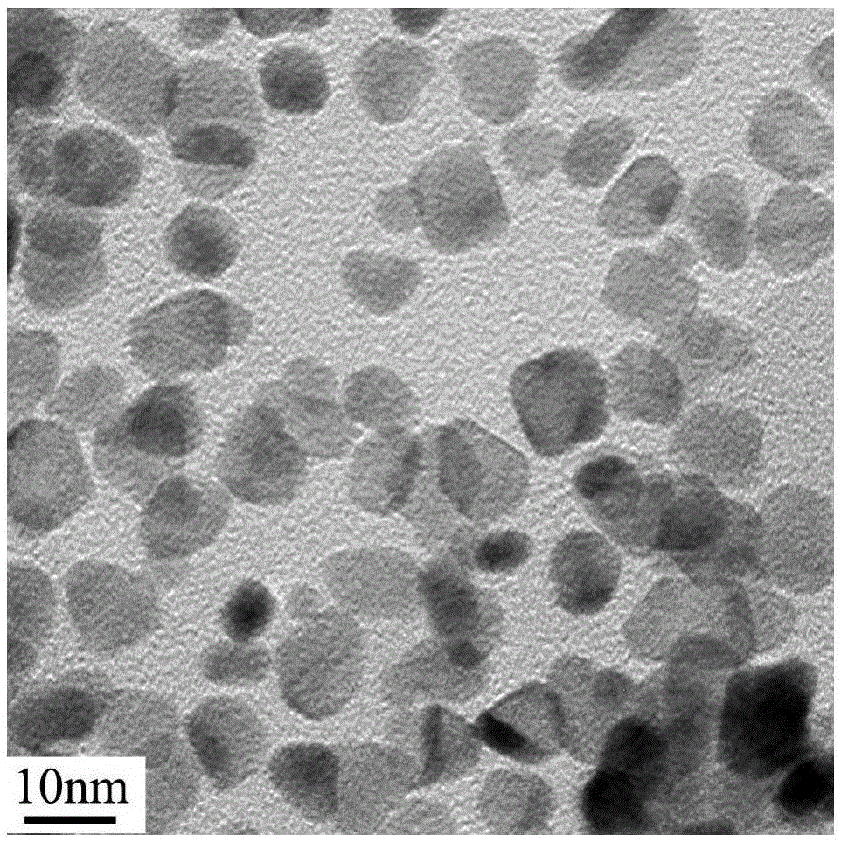

[0034] Embodiment 2, the preparation of monodisperse Pt1Pd5 nanoparticles

[0035] Take chloroplatinic acid and palladium chloride (the molar ratio of platinum to palladium is 1:5) and dissolve them in the mixed solution of formaldehyde and water (the volume ratio of formaldehyde and water is 1:6); Semisiloxane (the molar ratio of metal precursor and octaamic acid group silsesquioxane is 1:6), use 5mol / L hydrochloric acid or 5mol / L sodium hydroxide solution to adjust the pH value of the above mixed solution after ultrasonic oscillation To 7, keep stirring to fully contact and complex the stabilizer with Pd ions and Pt ions to obtain a mixed liquid of active metal precursor; transfer the prepared raw material liquid to a hydrothermal reaction kettle, the reaction temperature is 100°C, and the reaction time is 9h ; The reduced product is centrifugally washed with ultrapure water several times, and then dried in a vacuum desiccator (60° C.), and the obtained solid product is unif...

Embodiment 3

[0036] Embodiment 3, preparation of monodisperse Pt1Pd10 nanoparticles

[0037] Dissolve chloroplatinic acid and palladium chloride (the molar ratio of platinum to palladium is 1:10) in the mixed solution of formaldehyde and water (the volume ratio of formaldehyde and water is 1:3); Semisiloxane (the molar ratio of metal precursor and octaamic acid silsesquioxane is 1:3), use 5mol / L hydrochloric acid or 5mol / L sodium hydroxide solution to adjust the pH value of the above mixed solution after ultrasonic oscillation To 3, keep stirring to fully contact and complex the stabilizer with Pd ions and Pt ions to obtain a mixed liquid of active metal precursor; transfer the prepared raw material liquid to a hydrothermal reaction kettle, the reaction temperature is 140°C, and the reaction time is 12h ; The reduced product is centrifugally washed with ultrapure water several times, and then dried in a vacuum desiccator (60° C.), and the obtained solid product is uniformly dispersed Pt-Pd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com