Core-shell structure nanometer material for silver cores/platinum shells and preparation method of core-shell structure nanometer material

A technology of core-shell structure and nanomaterials, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem that the cost of platinum-based materials cannot be significantly reduced, and the catalytic activity cannot meet the existing needs and conditions. Unfriendly to the environment and other issues, to achieve the effect of low cost, easy operation and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get 0.0143g of sodium citrate and 0.060g of silver nitrate, dissolve them in 20mL of deionized water, place them in a flask and stir at room temperature; The solution turned from colorless and transparent to black, and then to brownish yellow. After continuous stirring for 24 hours, a silver seed solution was obtained.

[0028] Add 0.0600g of ascorbic acid and 0.0030g of sodium citrate to the prepared silver seed solution, heat to 80°C while stirring, then quickly add 0.0170g of chloroplatinic acid, and the reaction solution turns from brown to black and then kept at 95°C Stir, remove the reaction bottle after 1 hour, transfer the reaction solution to a centrifuge tube, and rotate at a speed of 11,000 rpm for 60 minutes. After centrifugation, pour off the supernatant and leave the precipitate to obtain a granular silver core / platinum shell core shell. Structural Nanomaterials.

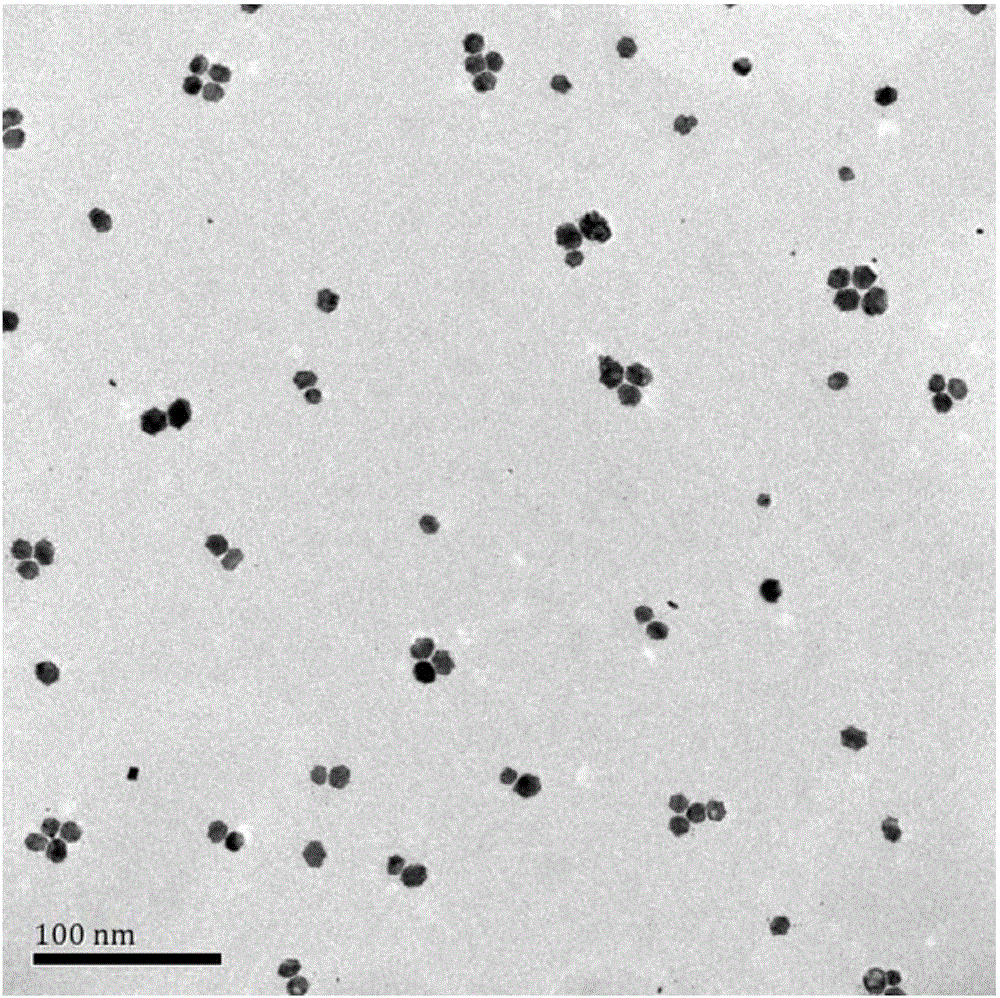

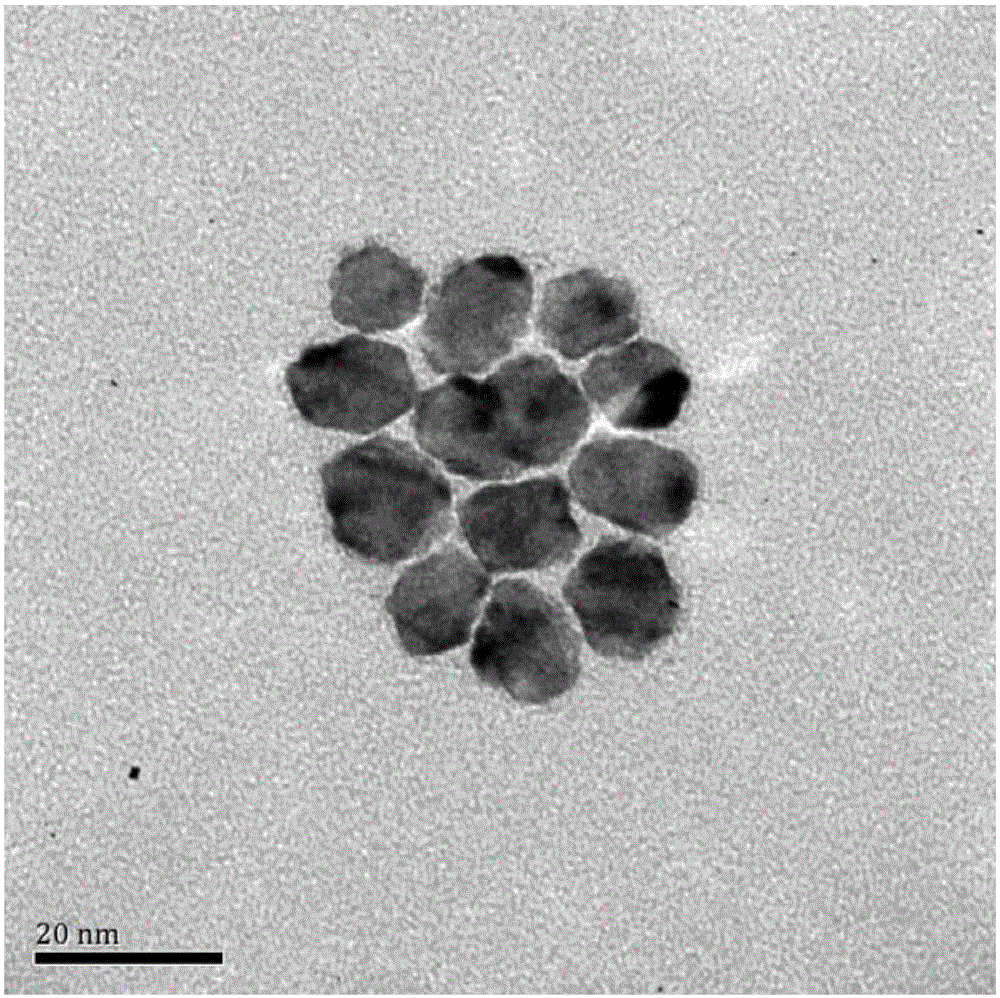

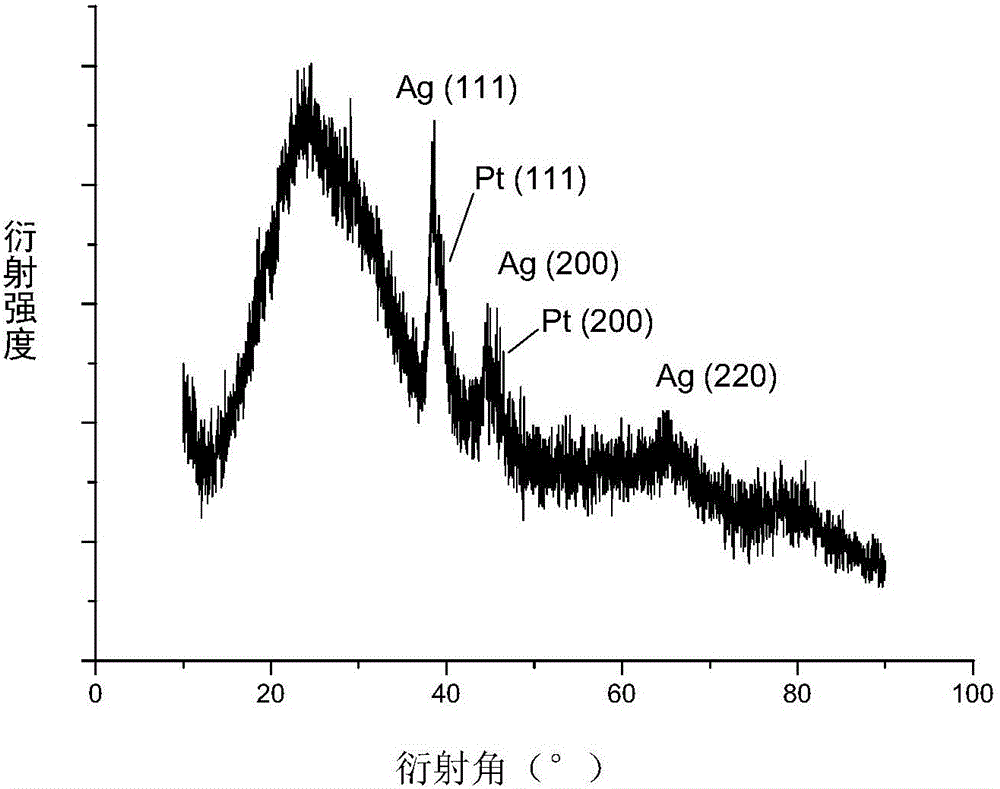

[0029] figure 1 The transmission electron microscope image of the core-shell structure nan...

Embodiment 2

[0031] Get 0.0143g of sodium citrate and 0.0060g of silver nitrate, dissolve them in 20mL of deionized water, place them in a flask and stir at room temperature; The solution turned from colorless and transparent to black, and then to brownish yellow. After continuous stirring for 24 hours, a silver seed solution was obtained.

[0032] Add 0.0550g of ascorbic acid and 0.0162g of polyvinylpyrrolidone (K=30) to the prepared silver seed crystal solution, heat to 90°C while stirring, then quickly drop 0.0140g of potassium tetrachloroplatinate, and the reaction solution changes from brown to yellow Keep stirring at 90°C after turning black, remove the reaction bottle after 0.5h, transfer the reaction solution to a centrifuge tube, and rotate at a speed of 11000rpm for 60min, pour off the supernatant after centrifugation, and leave the precipitate to obtain the granular Silver core / platinum shell core-shell nanomaterials.

[0033] Figure 4 The transmission electron microscope pic...

Embodiment 3

[0035] With the same method as in Example 1, the difference is that the input inorganic silver salt is 0.0110g of silver sulfate, after stirring at room temperature for 12 hours, the silver seed solution is obtained, and then the steps are the same as in Example 1, the only difference is the input Inorganic platinum salt is the chloroplatinic acid of 0.0174g, and final product is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com