C-SiC loaded platinum-based catalyst, preparation method and applications thereof

A catalyst, platinum-based technology, applied in the field of platinum-based catalysts, can solve the problems of non-resistance to sintering, low catalyst activity, etc., and achieve the effects of improving conversion rate, simple and feasible preparation method, and avoiding catalyst carbon deposition and deactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

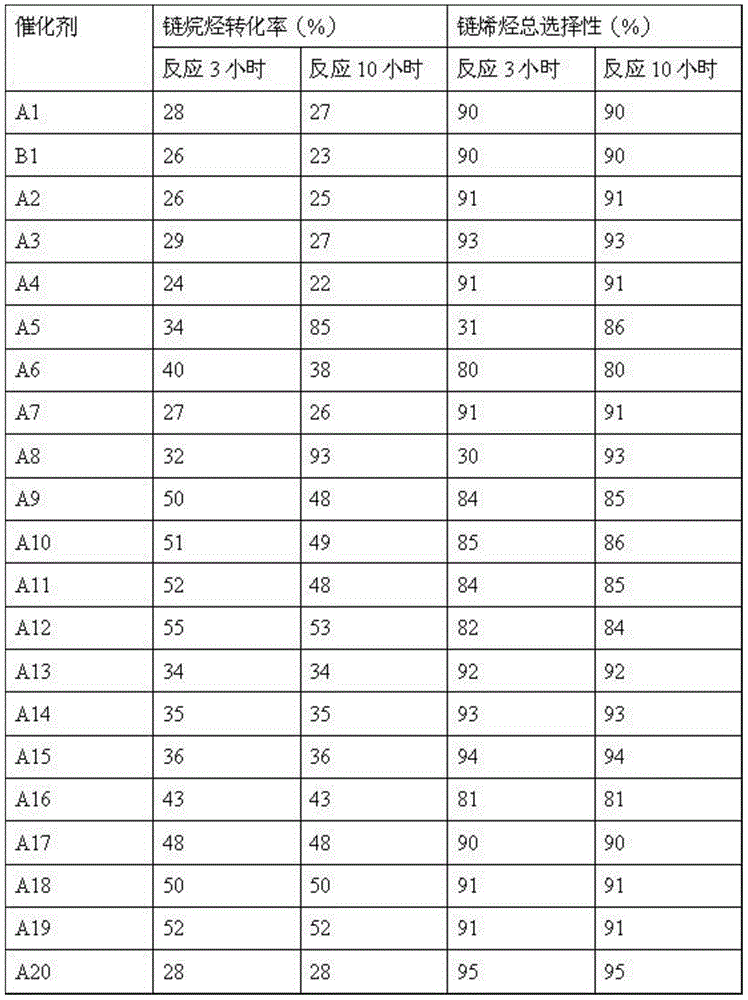

Examples

preparation example Construction

[0039] The preparation method of C-SiC supported platinum-based catalyst comprises the following steps:

[0040] (1) The step of contacting the platinum component precursor, the auxiliary element precursor and C-SiC according to a predetermined ratio (preferably in the presence of a dispersion medium such as water) to obtain a contact product (hereinafter referred to as the contact step);

[0041] (2) A step of calcining the contact product to obtain the C-SiC supported platinum-based catalyst (hereinafter referred to as the calcining step).

[0042] The predetermined ratio can be such that the composition of the C-SiC supported platinum-based catalyst finally obtained after the calcination step complies with the foregoing provisions of the present invention.

[0043] The platinum component precursor refers to the substance that can generate the platinum mentioned above through the roasting of the step (2), preferably the soluble salt and soluble acid of platinum, more prefera...

Embodiment approach

[0053] According to one embodiment of the present invention, the contacting step comprises the following steps:

[0054] (1a) Weighing a predetermined amount of platinum component precursor and additive element precursor, mixing and dissolving them in water, optionally adding an appropriate amount of pH regulator etc. as needed, to prepare an aqueous solution;

[0055] (1b) mixing a predetermined amount of C-SiC with the aqueous solution under stirring to obtain a mixed slurry; and

[0056] (1c) drying (such as at 60-150° C., preferably at 70-120° C.) the mixed slurry to obtain the contact product.

[0057] The "predetermined amount" specified here for the platinum component precursor, the auxiliary element precursor and C-SiC meets the requirements of the present invention with the composition of the C-SiC supported platinum-based catalyst finally obtained after the calcination step The foregoing provisions shall prevail, and no special provisions are required. In view of thi...

Embodiment 1

[0075] Dissolve 0.017g of platinum nitrate (molecular weight: 319.09) and 0.041g of lithium nitrate (molecular weight: 68.9) in 15ml of water to make a mixed solution of platinum nitrate and lithium nitrate, and add BET to the above solution with a surface area of 125m 2 g -1 20.1g CDC-SiC porous C-SiC sample with an average pore diameter of 12.2nm (prepared with reference to Journal of Materials Chemistry, 2012, Volume 22, pages 14155-14159), stirred in a constant temperature water bath at 80°C for 10 minutes, and dried at 120°C , and calcined at 620°C for 5 hours to obtain a C-SiC supported platinum-based catalyst, code-named A1, in which the mass percentage of Pt was determined to be 0.05%, and the mass percentage of Li was 0.02%. The prepared C-SiC supported platinum-based catalyst was loaded into a fixed-bed reactor, passed through hydrogen for reduction at 200°C for 5 hours, and then passed through a mixture of propane and hydrogen preheated to 340°C (volume ratio of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com