Platinum-palladium-platinum/manganese dioxide/graphene laminated catalyst and preparation method therefor

A structural catalyst, manganese dioxide technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the poisoning of precious metal electrocatalysts, loss of catalyst carrier value, Reduce catalyst loading points and other issues, achieve excellent electrochemical performance, improve CO poisoning resistance, and facilitate adsorption and oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

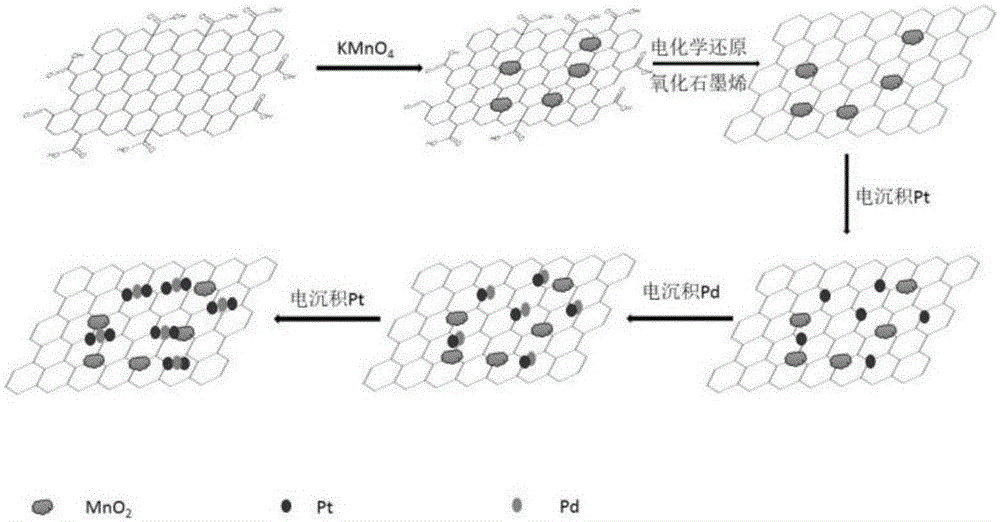

[0036] First, 15 mg of graphene oxide prepared by the modified hummers method was dissolved in 30 mL of deionized water, and ultrasonicated for 1 hour to obtain a yellow-brown uniform suspension. Then, with vigorous stirring, 1 mL of 0.05M potassium permanganate solution was quickly added, and the resulting mixed solution was stored at room temperature for 12 hours. After centrifugation, wash with deionized water and dry. A manganese dioxide-doped graphene oxide composite (MnO 2 / GO). Dissolve 1 mg of the complex prepared above in 1 mL of deionized water to obtain 1 mg / mL of MnO 2 / GO solution, sonicated for 1 hour. Immerse the three-electrode system (glassy carbon electrode, saturated calomel electrode and platinum wire electrode) in the solution, carry out cyclic voltammetry scanning, scan speed 25mV / s, scan 10 laps, obtain the graphene modification of manganese dioxide doping electrode (MnO 2 / G). Immerse the prepared electrode in 1mM chloroplatinic acid solution, and...

Embodiment 2

[0045] First, 15 mg of graphene oxide prepared by the modified hummers method was dissolved in 30 mL of deionized water, and ultrasonicated for 1 hour to obtain a yellow-brown uniform suspension. Then, with vigorous stirring, 1 mL of 0.05M potassium permanganate solution was quickly added, and the resulting mixed solution was stored at room temperature for 12 hours. After centrifugation, wash with deionized water and dry. A manganese dioxide-doped graphene oxide composite (MnO 2 / GO). Take 1mg of the above-prepared MnO 2 / GO was dissolved in 2 mL of deionized water to obtain 0.5 mg / mL of MnO 2 / GO solution, sonicated for 1 hour. Immerse the three-electrode system (glassy carbon electrode, saturated calomel electrode and platinum wire electrode) in the solution, carry out cyclic voltammetry scanning, scan speed 50mV / s, scan 30 circles, obtain the graphene modification of manganese dioxide doping the electrodes. Immerse the prepared electrode in 2mM chloroplatinic acid sol...

Embodiment 3

[0047] First, 15 mg of graphene oxide prepared by the modified hummers method was dissolved in 30 mL of deionized water, and ultrasonicated for 1 hour to obtain a yellow-brown uniform suspension. Then, with vigorous stirring, 1 mL of 0.05M potassium permanganate solution was quickly added, and the resulting mixed solution was stored at room temperature for 12 hours. After centrifugation, wash with deionized water and dry. Obtain a manganese dioxide doped graphene oxide composite MnO 2 / GO. Take 1.5mg of the above prepared MnO 2 / GO was dissolved in 2 mL of deionized water to obtain 0.75 mg / mL of MnO 2 / GO solution, sonicated for 1 hour. The three-electrode system (glassy carbon electrode, saturated calomel electrode and platinum wire electrode) was immersed in the solution, and a cyclic voltammetry scan was performed at a scan rate of 100mV / s for 20 cycles to obtain a manganese dioxide-doped graphene-modified The electrode MnO 2 / G. Immerse the prepared electrode in a 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com