Closed coating method for wood

A coating method and closed technology, which can be applied to devices for coating liquid on surfaces, coatings, pre-treatment surfaces, etc. Good coating effect, improve coating scale and efficiency, and increase the effect of layering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

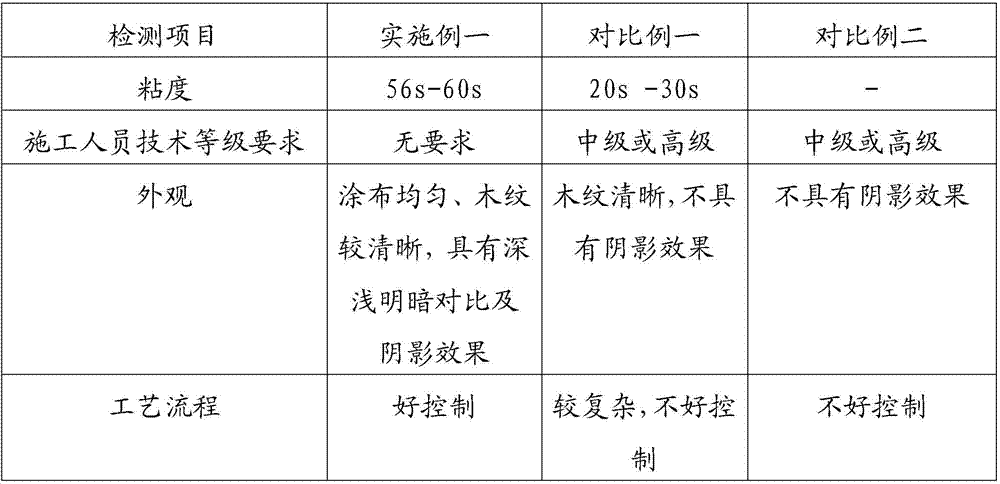

Embodiment 1

[0050] The closed coating method for woodware of the present invention adopts water-based woodware coating as the basic coating, wherein the water-based woodware coating comprises the following components in parts by weight: 44 parts of water-based polyurethane resin, 8 parts of transparent powder, 0.3 part of dispersant, and 0.2 parts of variable agent, 0.8 parts of thickener, 0.3 parts of wetting agent, 4.9 parts of water-based color paste, 1 part of film-forming aid, 40 parts of water, and 0.3 parts of defoamer. The dispersant is a fatty acid dispersant, the rheological agent is organic bentonite, the thickener is polyacrylate mixed with cellulose ether in a mass ratio of 1:1, and the wetting agent is polyoxyethylene alkylphenyl ether , Polyoxyethylene fatty acid ester is mixed in a mass ratio of 1:1, the film-forming aid is compounded with diethylene glycol butyl ether and ethylene glycol in a ratio of 3:1, and the defoamer is emulsified silicone oil.

[0051] The preparat...

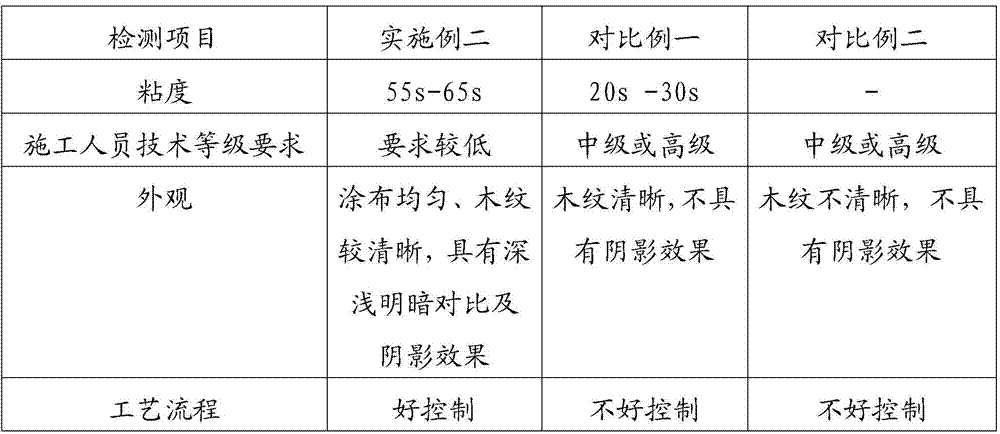

Embodiment 2

[0090] In the present embodiment, the water-based wood coating includes the following components by weight: 43 parts of water-based polyurethane resin, 7 parts of transparent powder, 0.2 part of dispersant, 0.1 part of rheological agent, 0.5 part of thickener, and 0.1 part of wetting agent , 4 parts of water-based color paste, 0.8 part of film-forming aid, 40 parts of water, and 0.3 part of defoamer. Wherein the dispersant adopts stearic acid monoglyceride, the rheological agent adopts polyamide wax and organic bentonite to mix with the mass ratio of 1:1, and the thickener adopts polyacrylate and bentonite to mix with the mass ratio of 1:2, moistens The wet agent is W2001 (Beijing Moke Company), the film-forming aid is made of ethylene glycol butyl ether and diethylene glycol butyl ether in a ratio of 2:1, and the defoamer is made of carbon alcohol fatty acid ester compound and Emulsified silicone oil is compounded at a ratio of 2:1.

[0091] The production method is to mix t...

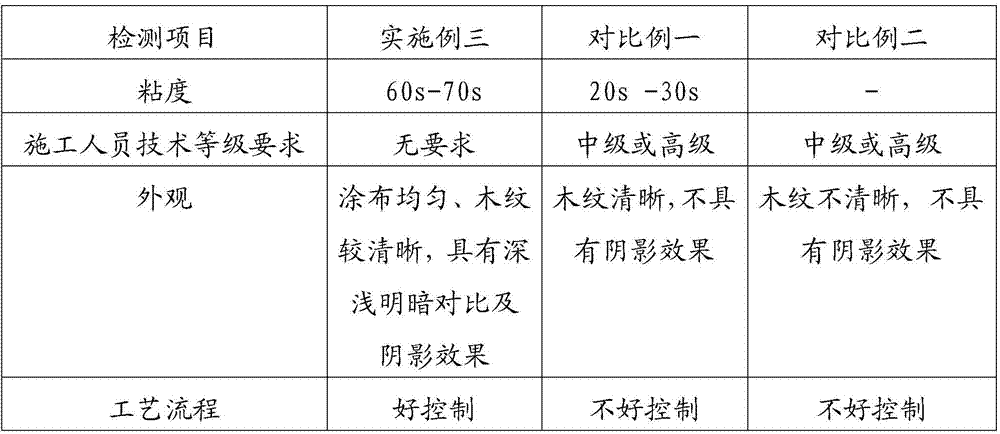

Embodiment 3

[0110] In the present embodiment, the water-based wood coating includes the following components by weight: 48 parts of acrylic resin, 9 parts of transparent powder, 0.4 part of dispersant, 0.3 part of rheological agent, 1.0 part of thickener, 0.4 part of wetting agent, 6 parts of water-based color paste, 1.2 parts of film-forming aid, 50 parts of water, and 0.3 part of defoamer. Among them, the film-forming aid is selected from propylene glycol butyl ether, the rheological agent is selected from castor oil derivatives and organic bentonite mixed with a mass ratio of 1:1, and the thickener is selected from bentonite, polyacrylate thickener and polyacrylate thickener. Mix at a mass ratio of 2:1:2, use W2001 (Beijing Moke Company) as the wetting agent, use acrylic acid copolymer potassium salt as the dispersant, and use emulsified silicone oil as the defoamer.

[0111] The production method is to mix the components of the above formula together and stir evenly. According to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com