Preparation method of halogen-free flame-retardant composition and flame-retardant polyolefin composition consisting of same

A technology for a composition and a flame retardant, applied in the field of flame retardant composition, can solve the problems of multiple equipment, cost, unfavorable flame retardant performance stability, etc., and achieves low equipment requirements, good industrial application prospects, and simple and easy process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

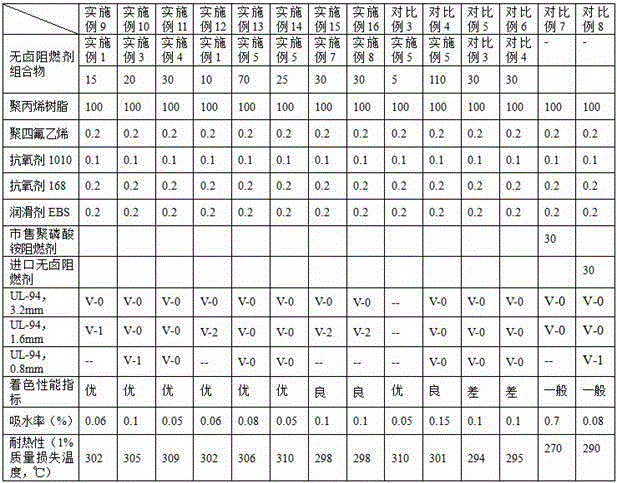

Examples

Embodiment 1

[0061] Put melamine phosphate and piperazine diphosphate at a molar ratio of 3:1, with a total weight of 100kg, 1kg of nano-zinc oxide, 1kg of dimethyl polysiloxane, and 3kg of nano-calcium silicate as activation aids, and place them in a high-speed mixer After stirring and mixing uniformly in the medium, the premix of the halogen-free flame retardant composition was obtained; then the premix of the halogen-free flame retardant composition was placed in a Banbury mixer for high-temperature dehydration condensation reaction to obtain 97.2kg of coke (poly ) melamine phosphate and piperazine pyro(poly)phosphate as the main components of a halogen-free flame retardant composition, wherein the vacuum degree is controlled at 0.025MPa, the dehydration condensation temperature is 250°C, the rotation speed is 20rpm, and the heating time is 4h; The appearance, yield, phosphorus content and whiteness index (W value) of the halogen-free flame retardant composition were tested, and the resu...

Embodiment 2

[0063] The molar ratio of melamine phosphate and piperazine diphosphate is 2.5:1, and the others are the same as in Example 1; the appearance, yield, phosphorus content and whiteness index (W value) of the halogen-free flame retardant composition were tested, and the results Listed in Table 1.

Embodiment 3

[0065] The molar ratio of melamine phosphate and piperazine diphosphate is 2:1, and the others are the same as in Example 1; the appearance, yield, phosphorus content and whiteness index (W value) of the halogen-free flame retardant composition were tested, and the results Listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com