Preparation method of hydroxylapatite coating on surface of titanium alloy matrix

A hydroxyapatite and medium hydroxyapatite technology, which is applied in metal material coating process, coating and other directions, can solve the problem of difficult to meet the needs of clinical application of life, safety and reliability, and has degradability and poor process reproducibility. and other problems, to achieve the effect of promoting long-term stability, simple preparation process and good coating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

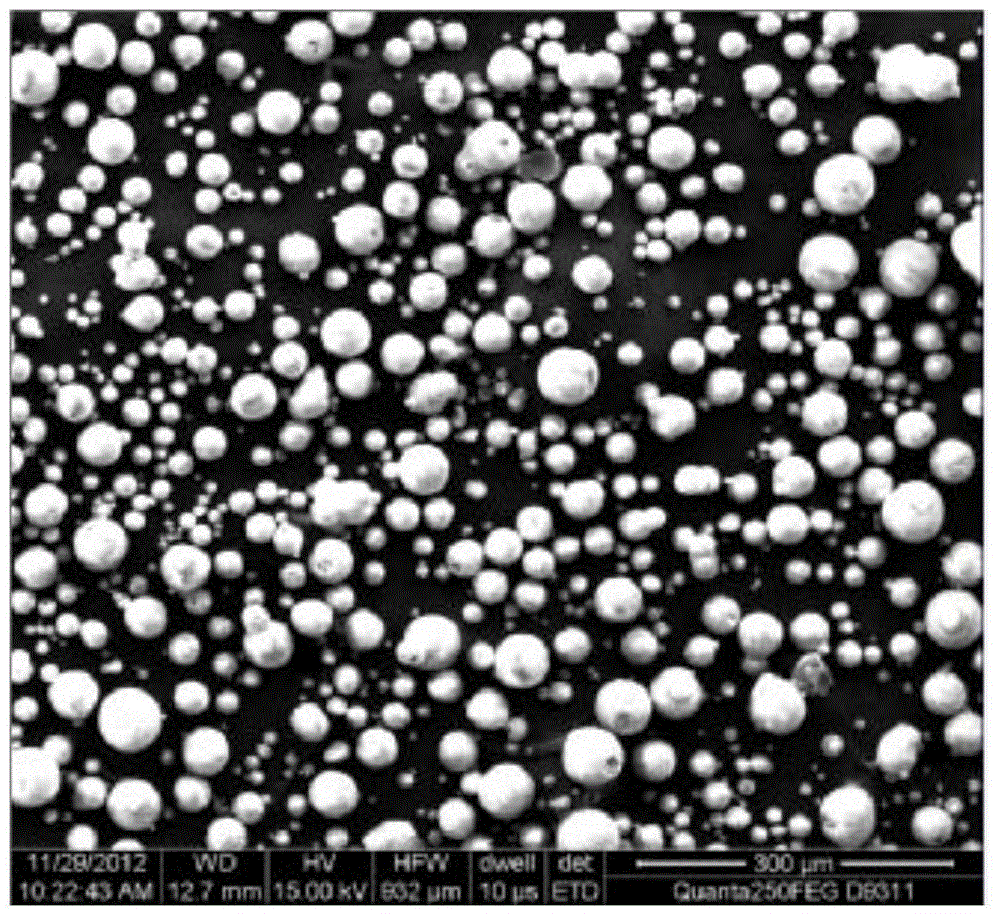

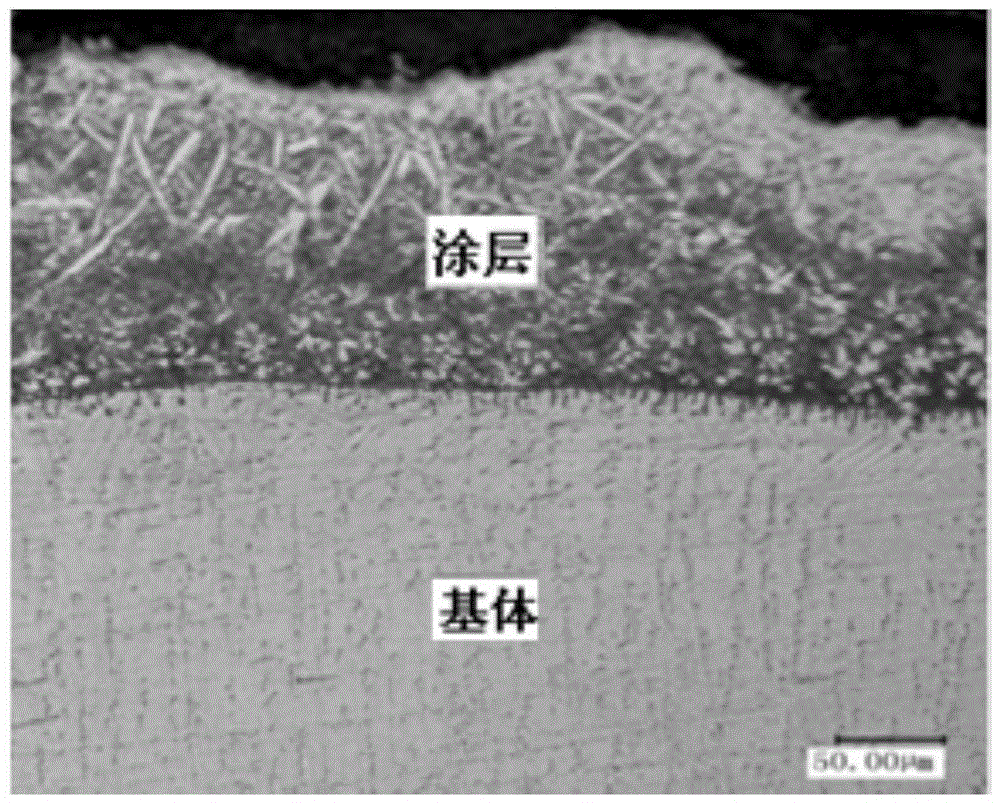

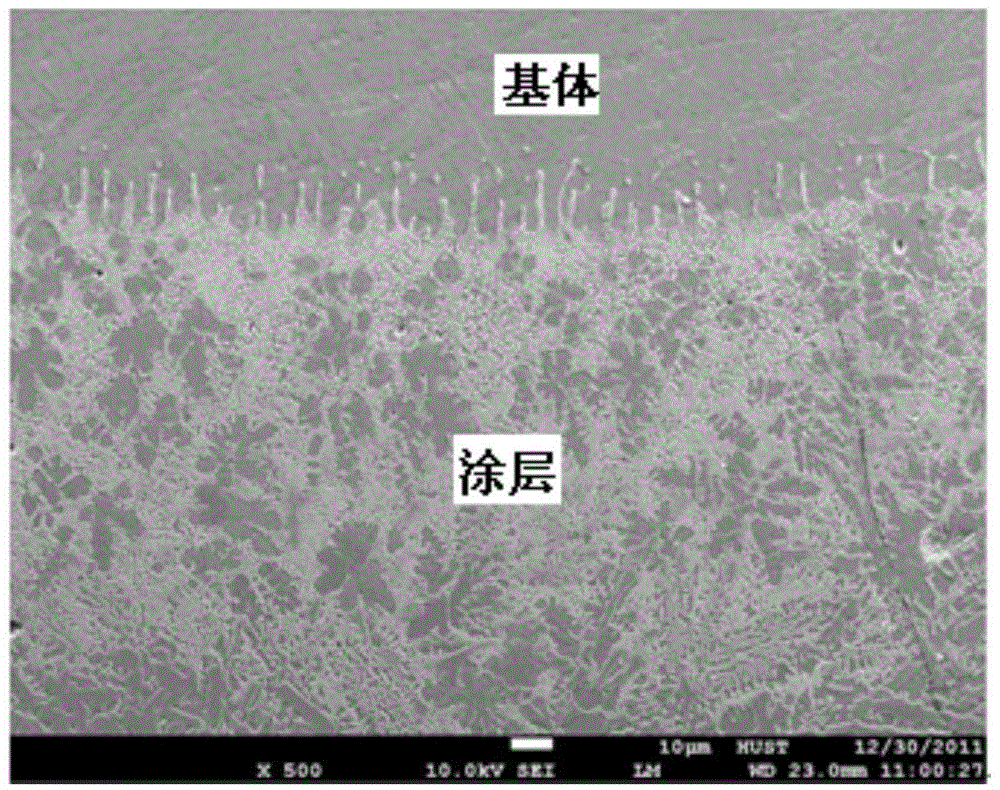

[0020] The Ti (titanium) powder and HA (hydroxyapatite) powder are respectively subjected to gas atomization granulation treatment to produce titanium powder and hydroxyapatite powder with a particle size of 10 μm. The gas atomization granulation treatment parameters are: room temperature The temperature is 200°C, the rotation speed of the atomizing disc is 180r / s, and the feeding rate is 20ml / min; the morphology of the hydroxyapatite powder after atomization and granulation is as follows figure 1 As shown, the titanium powder and hydroxyapatite powder processed by gas atomization granulation were then mechanically mixed uniformly to prepare a Ti-HA mixed powder with a particle size of 10 μm, wherein the content of HA powder was 60%. Use sandpaper and acetone to remove surface rust and oil stains on the surface of the titanium alloy substrate, and then use quartz sand with a particle size of 30 mesh to perform sandblasting and roughening treatment. Put the mixed Ti and HA powd...

Embodiment 2

[0024] The Ti powder and HA powder were respectively subjected to gas atomization granulation treatment, and the particle size was both 20 μ m of titanium powder and hydroxyapatite powder, the gas atomization granulation treatment parameters are as follows: the room temperature is 205°C, the atomization disc rotation speed is 190r / s, and the feeding rate is 25ml / min; then the gas atomization granulation treatment The titanium powder and the hydroxyapatite powder were uniformly mixed mechanically to prepare a Ti-HA mixed powder with a particle size of 20 μm, wherein the content of the HA powder was 70%. Use sandpaper and acetone to remove surface rust and oil stains on the surface of the titanium alloy substrate, and then use quartz sand with a particle size of 20 to roughen it by sandblasting. Put the prepared Ti powder and HA powder into the cold spray powder feeder for spraying. The spraying process is: both the working gas and the powder feeding gas are N 2 , the working g...

Embodiment 3

[0028] The Ti (titanium) powder and HA (hydroxyapatite) powder are respectively subjected to gas atomization granulation treatment to produce titanium powder and hydroxyapatite powder with a particle size of 25 μm. The gas atomization granulation treatment parameters are: The temperature is 210°C, the rotation speed of the atomizing disc is 200r / s, and the feeding rate is 30ml / min; then the titanium powder and hydroxyapatite powder after gas atomization and granulation are mechanically mixed to make a Ti-HA mixed powder, wherein The content of HA powder was 75%. Use sandpaper and acetone to remove surface rust and oil stains on the surface of the titanium alloy substrate, and then perform sandblasting roughening treatment with quartz sand with a particle size of 25 mesh. Put the prepared Ti powder and HA powder into the cold spray powder feeder for spraying. The spraying process is: both the working gas and the powder feeding gas are N 2 , the working gas pressure is 3.6MPa, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com