Low-sodium high-potassium salinity-increased composite solid seasoner and preparation method thereof

A seasoning and high-potassium technology, which is applied in the field of low-sodium and high-potassium salt-increasing compound solid seasoning and its preparation, can solve the problems of unfavorable human health, uneven mixing, high production cost, etc., and achieve the benefits of human health and cooking, and benefit The effect of uniform mixing and uniform saltiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

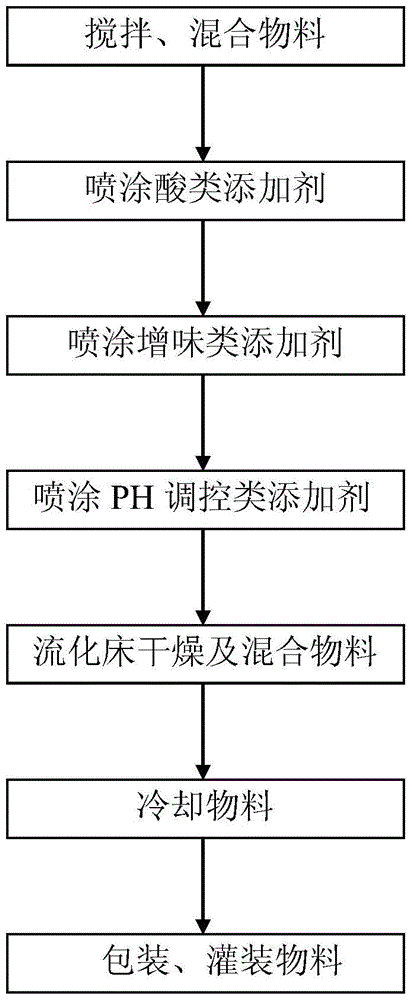

Method used

Image

Examples

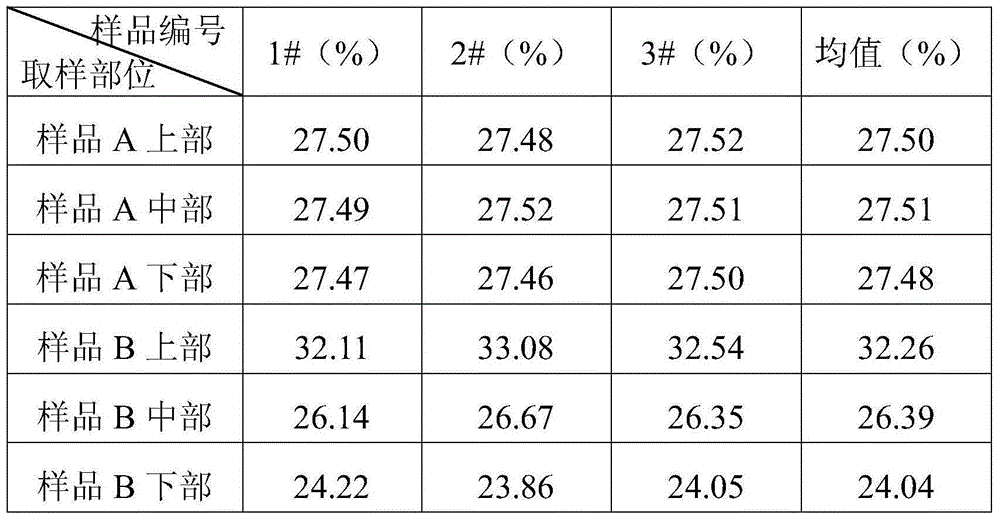

Embodiment 1

[0056] Set the bulk density to 1.2g / cm 3 45kg of refined edible sodium chloride with a particle size of 20-80 meshes and a bulk density of 1.18g / cm 3 40kg of edible potassium chloride, 10kg of selenium-enriched maltodextrin, 5kg of selenium-enriched water-soluble starch, and 2kg of chicken bouillon, with a particle size of 20-80 mesh, are mixed in a stainless steel stirring device. The mixing environment temperature is 20°C and the relative humidity is 40%. The stirring speed was controlled at 300r / min, and mixed for 20 minutes to obtain material 1;

[0057] The mixed material 1 is conveyed with a PP material belt. During the process of conveying the material 1 by the belt, the prepared 3kg acid additive is evenly sprayed on the surface of the material 1 with an atomizer to obtain the material 2. Among them, The acid additive is a mixed solution of citric acid, lactic acid and phosphoric acid;

[0058] While the belt continues to transport the material 2, use an atomizer to ...

Embodiment 2

[0063] Set the bulk density to 1.2g / cm 3 50kg of refined edible sodium chloride with a particle size of 20-80 meshes and a bulk density of 1.18g / cm 3 37kg of edible potassium chloride with a particle size of 20-80 meshes, 5kg of selenium-enriched maltodextrin, 10kg of selenium-enriched water-soluble starch, and 3kg of chicken bouillon are mixed in a stainless steel stirring device. The mixing environment temperature is 20°C and the relative humidity is 40%. The stirring speed was controlled at 300r / min, and mixed for 20 minutes to obtain material 1;

[0064] The mixed material 1 is conveyed with a belt made of PP material. During the process of conveying the material 1 by the belt, the prepared 1.5kg acid additive is evenly sprayed on the surface of the material 1 with an atomizer to obtain the material 2, wherein , the acid additive is a mixture of citric acid, lactic acid, and succinic acid;

[0065] While the belt continues to transport the material 2, use an atomizer to ...

Embodiment 3

[0070] Set the bulk density to 1.2g / cm 3 60kg of refined edible sodium chloride with a particle size of 20-80 meshes and a bulk density of 1.18g / cm 3 25kg of edible potassium chloride, 7kg of selenium-enriched maltodextrin, 8kg of selenium-enriched water-soluble starch, and 5kg of chicken bouillon, with a particle size of 20-80 mesh, are mixed in a stainless steel stirring device. The mixing environment temperature is 20°C and the relative humidity is 40%. The stirring speed was controlled at 300r / min, and mixed for 20 minutes to obtain material 1;

[0071] The mixed material 1 is conveyed with a belt made of PP material. During the process of conveying the material 1 by the belt, 1.2 kg of acid additives prepared by the atomizer are evenly sprayed on the surface of the material 1 to obtain the material 2, wherein , the acid additive is a mixed solution of citric acid and lactic acid;

[0072] While the belt continues to transport the material 2, the prepared 0.6 kg of flavo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com