Anti-aging cosmetic containing seaweed extract and preparation method thereof

A seaweed extract, anti-aging technology, applied in the field of plant extracts and daily chemicals, can solve the problems of high processing cost, cumbersome steps, cumbersome processing methods and the like of polymeric polysaccharide particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

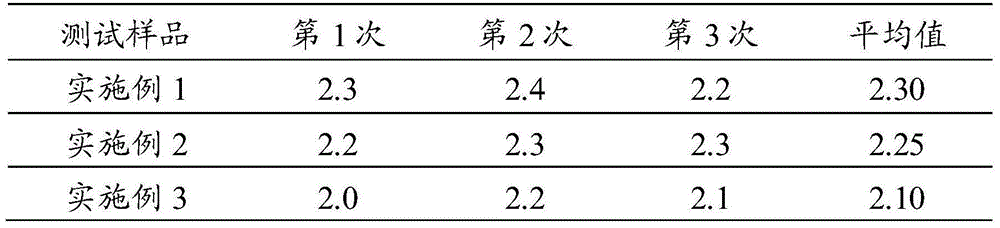

Examples

Embodiment 1

[0025] In parts by weight, take 1 part of PEG-100 stearate; 0.5 parts of cetearyl alcohol; 3 parts of caprylic / capric triglycerides, 0.2 parts of carbomer; 0.4 parts of scleroglucan; 3 parts of olive oil 0.05 part of methylparaben and 0.02 part of propylparaben are heated and melted in an oil phase pot, heated and stirred to melt at 80-85°C to obtain an oil phase solution;

[0026] Stir and dissolve 6 parts of seaweed extract, 5 parts of glycerin, and 63 parts of deionized water in a water phase pot, heat and stir to 80-85°C to obtain a water phase, and then add the oil phase solution in step 1) to the aqueous solution , homogenized for 5 minutes, then added 0.5 parts of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer, and homogenized for another 5 minutes. At 45°C, add 0.5 part of triethanolamine and 0.01 part of essence. Stir evenly, discharge at 38°C, cool down to room temperature naturally, fill and pack.

[0027] The preparation method of the seaweed ex...

Embodiment 2

[0034] In parts by weight, take 3 parts of PEG-100 stearate; 0.5 part of carbomer; 0.6 part of scleroglucan; 5 parts of olive oil; 1.0 part of cetearyl alcohol; 0.2 parts of methylparaben and 0.1 part of propylparaben are heated and melted in an oil phase pot, heated and stirred to melt at 80-85°C to obtain an oil phase solution;

[0035] Stir and dissolve 8 parts of seaweed extract, 9 parts of glycerin, and 80 parts of water in a water phase pot, heat and stir to 80-85°C to obtain a water phase, then add the oil phase solution in step 1) to the aqueous solution, and mix After massaging for 5 minutes, add 2 parts of acrylic acid (ester) / C10-30 alkanol acrylate cross-linked polymer, homogenize for another 5 minutes, keep stirring for 20 minutes, turn on cooling water to cool to 40-45°C, add three 3 parts of ethanolamine, 0.1 part of essence. Stir evenly, discharge at 38°C, cool down to room temperature naturally, fill and pack.

[0036] The extraction method of the seaweed extr...

Embodiment 3

[0038] In parts by weight, take 2 parts of PEG-100 stearate; 0.3 part of carbomer; 0.5 part of scleroglucan; 4 parts of olive oil; 0.8 part of cetearyl alcohol; caprylic / capric triglyceride 4 0.1 part of methylparaben and 0.05 part of propylparaben are heated and melted in an oil phase pot, heated and stirred to melt at 80-85°C to obtain an oil phase solution;

[0039] Take 7 parts of seaweed extract; 7 parts of glycerin and 71.49 parts of water are stirred and dissolved in a water phase pot, heated and stirred to 80-85°C to obtain a water phase, and then the oil phase solution in step 1) is added to the aqueous solution, and the After massaging for 5 minutes, add 1.2 parts of acrylic acid (ester) / C10-30 alkanol acrylate crosslinked polymer, and then homogenize for 5 minutes.

[0040] After heat preservation and stirring for 20 minutes, turn on cooling water to cool to 40-45°C, add 1.5 parts of triethanolamine and 0.06 parts of essence. Stir evenly, discharge at 38°C, cool do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com