Regeneration method of noble metal catalyst

A technology for catalysts and dehydrogenation catalysts, which is applied in the regeneration field of propane and isobutane dehydrogenation noble metal-based catalysts. It can solve problems such as metal aggregation, alkali metal loss, and alumina carrier crystal phase transition, and achieves small temperature changes and easy Operation and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh commercially available alumina carrier (γ phase, spherical, diameter 0.5mm, pore volume 0.71cm 3 / g, specific surface area 224m 2 / g) 30g, add deionized water dropwise to initial moistening, and the volume of consumed water is 27mL. Based on the weight content of 0.4% of the Sn element in the final catalyst, stannous chloride containing 0.12 g of Sn was weighed and dissolved in ethanol, and the volume was adjusted to 27 mL with ethanol. The prepared Sn-containing ethanol solution was added to 30 g of alumina carrier, mixed evenly, and aged at room temperature for 2 hours. Dry at 80°C for 8h, then bake at 600°C for 4h.

[0030] Based on the weight content of 0.5% of the Pt element in the final catalyst, weigh 0.18g of Pt-containing chloroplatinic acid and dissolve it in deionized water, set the volume to 27mL, add it to the Sn-containing alumina carrier, mix well, and age at room temperature for 4h. Dry at 100°C for 6h, and bake at 600°C for 4h. The sample obta...

Embodiment 2

[0033] Weigh commercially available alumina carrier (γ phase, spherical, diameter 0.5mm, pore volume 0.71cm 3 / g, specific surface area 224m 2 / g) 30g, add deionized water dropwise to initial moistening, and the volume of consumed water is 27mL. Based on the weight content of 0.6% of the Sn element in the final catalyst, stannous chloride containing 0.18g of Sn was weighed and dissolved in ethanol, and the volume was adjusted to 27mL. The prepared Sn-containing ethanol solution was added to 30 g of alumina carrier, mixed evenly, and aged at room temperature for 4 hours. Dry at 100°C for 6h, then bake at 500°C for 6h.

[0034] Based on the weight content of 0.7% of the Pt element in the final catalyst, weigh 0.12 g of Pt-containing chloroplatinic acid and dissolve it in deionized water, set the volume to 27 mL, add it to the Sn-containing alumina carrier, mix well, and age at room temperature for 2 h. Dry at 120°C for 4h, and bake at 500°C for 6h. The sample obtained in the...

Embodiment 3

[0037] After the C-1 fresh agent reacted for 72 hours, switch the raw material gas to pure hydrogen gas, purging for 1 hour, then the temperature dropped to 450°C, the pressure rose to 8MPa, and then hydrogen and tetralin were introduced at the same time. The speed is 1.5h -1 , the volume ratio of hydrogen to tetralin is 350, and the treatment time is 3h. After the treatment, switch to nitrogen, drop to normal pressure and room temperature, pass through cyclohexane to clean the deactivated catalyst, and then purging at 100°C for 3h in a nitrogen atmosphere. Under a nitrogen atmosphere, raise the temperature of the deactivated catalyst to 550°C, raise the pressure to 0.5MPa, and then feed a mixed gas of carbon dioxide and nitrous oxide. The volume content of nitrous oxide in the mixed gas is 0.5%, and the volume space velocity is 2000h -1 , the processing time is 3h. Obtain C-1 primary regeneration agent.

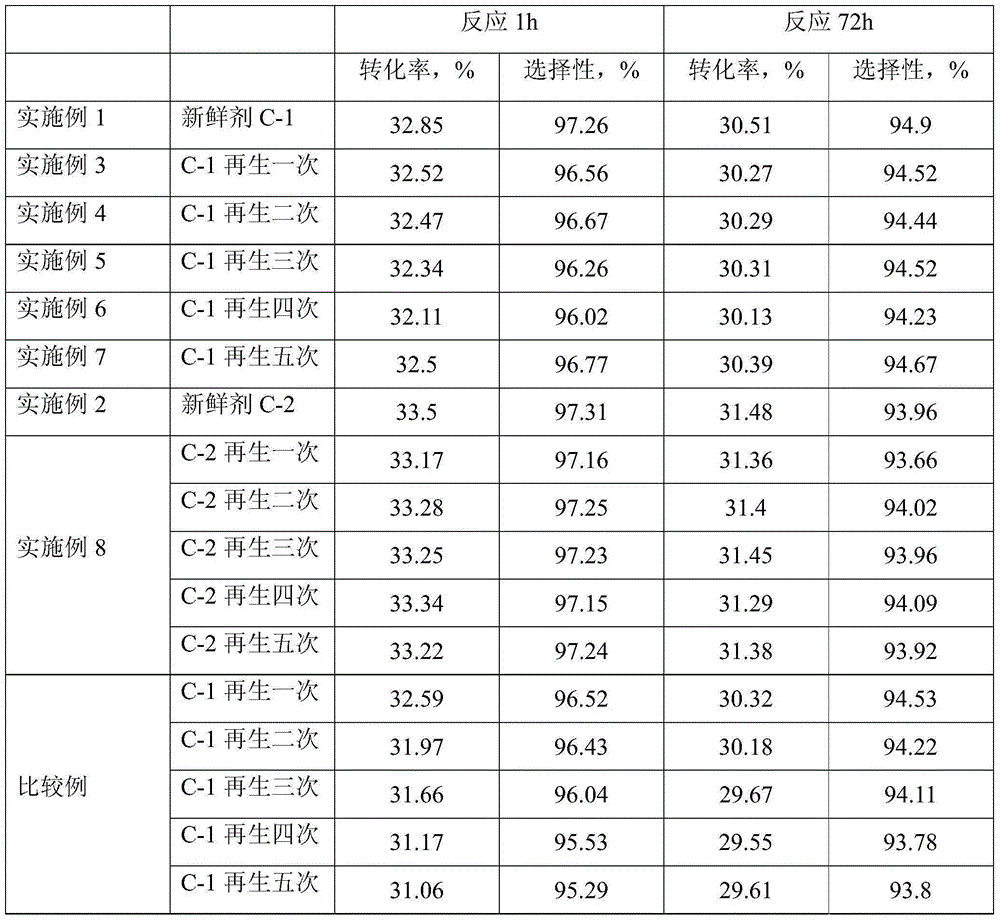

[0038] The reaction performance of C-1 primary regeneration agent is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com