Modified polyvinyl alcohol cornea repair material with collagen in graded distribution and preparation method

A technology of polyvinyl alcohol cornea and gradient distribution, applied in medical science, prostheses, etc., can solve the problems of lack of biological activity, poor cell adhesion, etc., and achieve the effect of simple equipment, simple preparation process, and excellent light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Polyvinyl alcohol (the degree of alcoholysis is 95%, and the weight average molecular weight Mw is 9000) is formulated with deionized water into a polyvinyl alcohol solution with a mass fraction of 10%, at a temperature of 90 to 98°C and a pressure of 600mmHg Remove air bubbles under vacuum conditions, and let stand at 90-98°C for 1.5 hours, then cool at room temperature, when the temperature of the polyvinyl alcohol solution is 50°C-60°C, pour 5ml of polyvinyl alcohol solution to a diameter of 1.5 cm disc mold, and pave it flat, freeze the mold at -20°C for 16 hours to obtain a frozen polyvinyl alcohol solution;

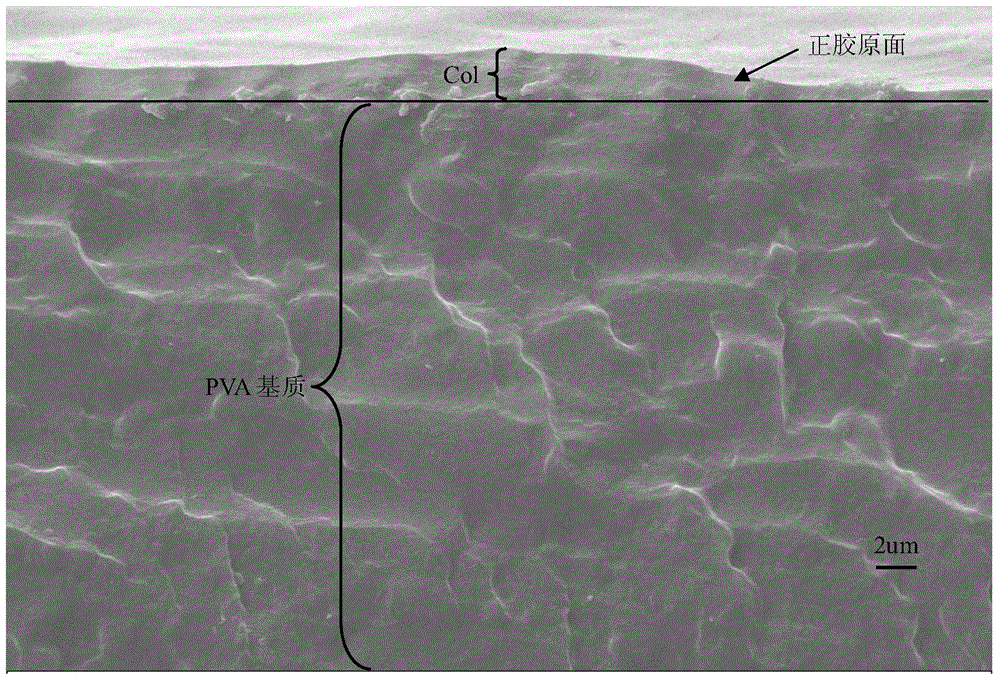

[0032] (2) Take the mold together with the frozen polyvinyl alcohol solution out of the -20°C environment and place it in a 25°C environment, and quickly spread 1ml of collagen solution evenly on the surface of the frozen polyvinyl alcohol solution (mass volume concentration is 4.0mg / ml of type I collagen acetic acid solution), and then thawed at 25°C fo...

Embodiment 2

[0041] (1) Polyvinyl alcohol (alcoholysis degree is 96%, weight-average molecular weight Mw is 9500) is mixed with deionized water into a polyvinyl alcohol solution with a mass fraction of 15%, at a temperature of 90 to 98°C and a pressure of 600mmHg Under the condition of vacuum to remove air bubbles, let stand at 90-98°C for 1 hour, then cool at room temperature, when the temperature of the polyvinyl alcohol solution is 50°C-60°C, pour 10ml of polyvinyl alcohol solution to a diameter of 1.5 cm disc mold, and lay it flat, and freeze the mold at -20°C for 16 hours to obtain a frozen polyvinyl alcohol solution;

[0042] (2) Take the mold together with the frozen polyvinyl alcohol solution out of the -20°C environment and place it in a 25°C environment, and quickly apply 10ml of collagen solution evenly on the surface of the frozen polyvinyl alcohol solution (mass volume concentration is 10mg / ml Type I collagen acetic acid solution), and then thawed at 25°C for 8 hours to obtain...

Embodiment 3

[0047] (1) Polyvinyl alcohol (the degree of alcoholysis is 97%, and the weight average molecular weight Mw is 10000) is formulated with deionized water into a polyvinyl alcohol solution with a mass fraction of 20%, at a temperature of 90 to 98°C and a pressure of 600mmHg Remove air bubbles under vacuum conditions, and let stand at 90-98°C for 2 hours, then cool at room temperature, when the temperature of the polyvinyl alcohol solution is 50°C-60°C, pour 10ml of polyvinyl alcohol solution to a diameter of 1.5 cm disc mold, and pave it flat, freeze the mold at -20°C for 16 hours to obtain a frozen polyvinyl alcohol solution;

[0048] (2) Take the mold together with the frozen polyvinyl alcohol solution out of the -20°C environment and place it in an environment of 25°C, and quickly apply 5ml of collagen solution evenly on the surface of the frozen polyvinyl alcohol solution (mass volume concentration is 15mg / ml Type I collagen acetic acid solution), and then thawed at 25°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com