Anti-coking semisynthesis heat conduction oil and preparation method thereof

A semi-synthetic heat transfer oil technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of poor thermal stability of mineral heat transfer oil, oxygen sensitivity of heat transfer oil, low oxidation sensitivity, etc., and achieve long-term stability Reliable and continuous work, not easy to coke, good anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

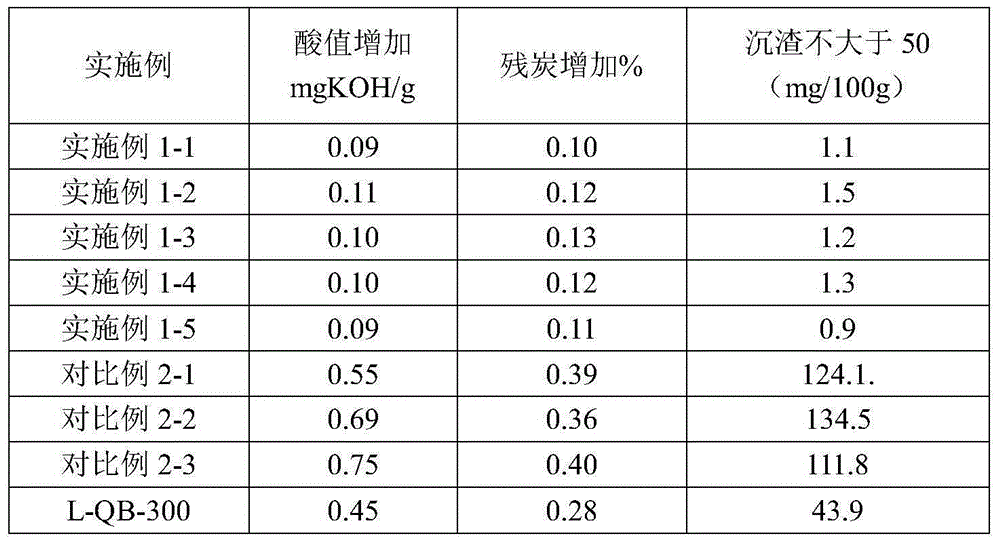

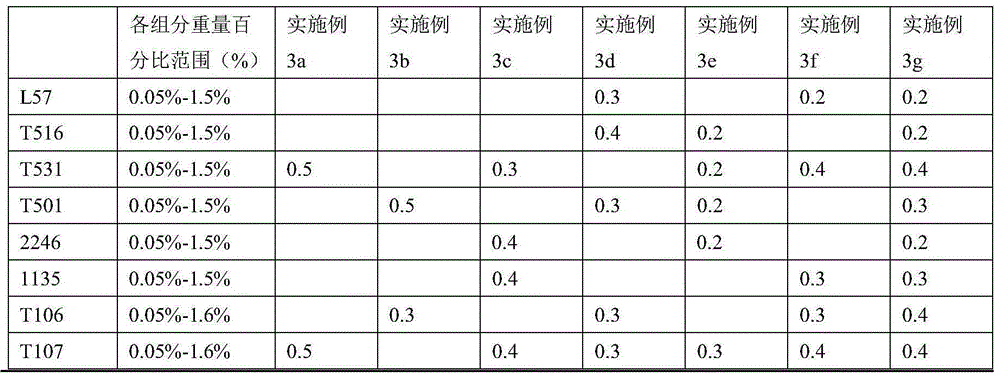

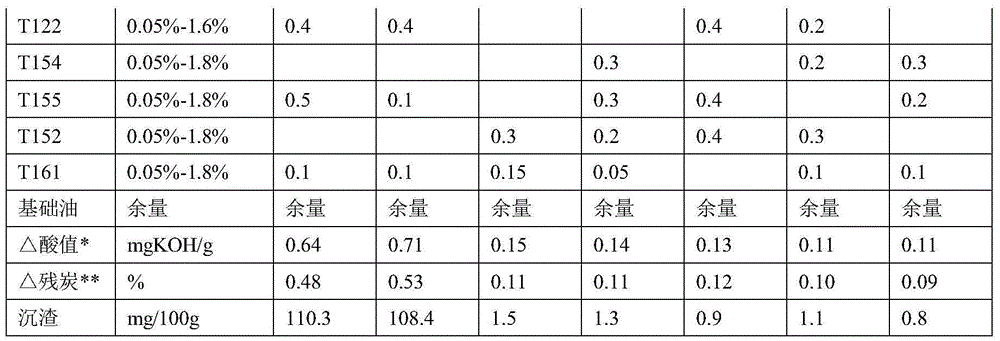

Examples

Embodiment 1-1

[0049] The anti-coking semi-synthetic heat transfer oil is 1000Kg in total, including 500Kg of HVI150 mineral base oil and 478Kg of synthetic base oil. Heat it to 120°C and keep it for 3 hours to remove moisture and light components in the base oil. Analysis shows the moisture content in the base oil 500mg / Kg. Add solid additive 22464Kg and stir to dissolve completely. Cool down to 80°C, add the remaining liquid additives T5344Kg, T1064Kg, T1224Kg, T1556Kg, stir for 30-45min, and mix well to obtain the finished anti-coking semi-synthetic heat transfer oil. The base oil after mixing the mineral base oil and synthetic aromatics: initial boiling point > 300°C, kinematic viscosity (40°C) less than 25mm 2 / s, residual carbon <0.04%, acid value <0.04mgKOH / g, copper corrosion less than 1 grade.

Embodiment 1-2

[0053] The anti-coking semi-synthetic heat transfer oil is 1000Kg in total, including 700Kg of HVI150 mineral base oil, 281.5Kg of synthetic aromatic base oil, L573.5Kg, T5014Kg, T1224.5Kg, and T1546.5Kg.

Embodiment 1-3

[0057] Select highly refined MVI mineral oil as the base oil 485.5Kg and mix 485.5Kg of synthetic aromatics, stir evenly, heat to 120°C, keep for 1-2 hours, remove moisture and light components in the base oil, analysis shows that the base oil Medium moisture content 50mg / Kg. Add solid additives: T5163Kg, T5013Kg, 22463Kg, stir until completely dissolved. Continue to cool down to 80°C, add L573Kg, T1074Kg, T1064Kg, T1559Kg in turn, stir at 60 rpm for 30 minutes, filter through a cartridge filter with a filter hole size of 1 μm, and pack to obtain the finished anti-coking semi-synthetic heat transfer oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| autoignition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com