Method of detecting content of preservative in cosmetic

A technology for preservatives and cosmetics, applied in the fields of analytical chemistry and daily chemical safety, can solve problems such as toxicity, and achieve the effects of low quantitative concentration, sensitive and accurate detection, and wide linear range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

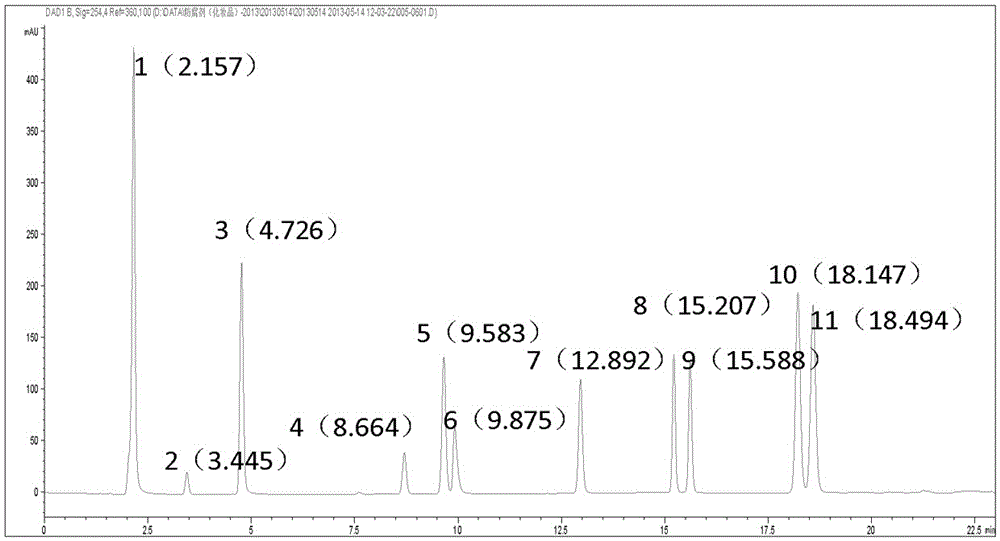

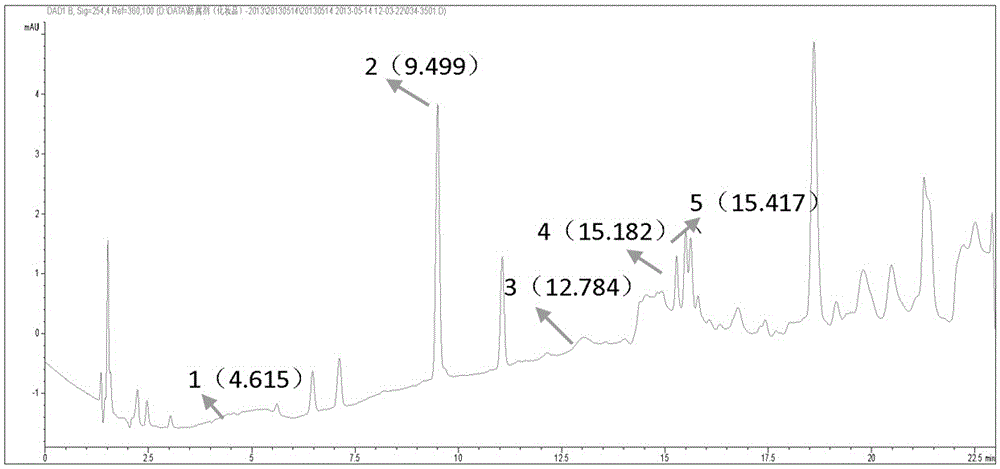

[0035] Embodiment 1 adopts method of the present invention to detect preservative content in cosmetics

[0036] Instruments: Agilent1260InfinityHPLC high-performance liquid chromatography system with PDA detector (Agilent); electronic balance (MettlerToledoNewClassicMF); ultrasonic cleaner (ElmasonicD-7700); centrifuge (Sigma3k15).

[0037] Standard products: methylisothiazolinone (content 99.0%), 2-bromo-2-nitropropane-1,3-diol (content 99.0%), methylchloroisothiazolinone (content 99.0%), Phenoxyethanol (content 99.5%), methyl 4-hydroxybenzoate (content 99.5%), benzoic acid (content 99.5%), ethyl 4-hydroxybenzoate (content 99.5%), isopropyl 4-hydroxybenzoate Esters (99.8%), Propyl 4-Hydroxybenzoate (99.5%), Isobutyl 4-Hydroxybenzoate (99.7%), Butyl 4-Hydroxybenzoate (99.0%), a total of 11 types , Manufacturers are: Dr. Ehrenstorfer GmbH.

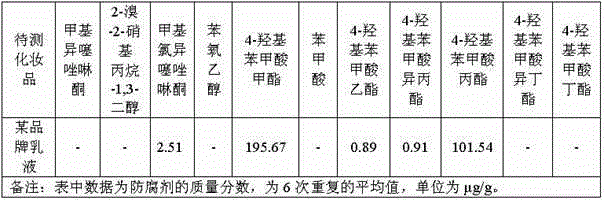

[0038] Cosmetics to be tested: lotion of a certain brand

[0039] Reagents: acetonitrile and methanol are chromatographically pure (DIM...

Embodiment 2

[0057] Day-to-day reproducibility test in embodiment 2

[0058] The method of Example 1 was used for 3 consecutive days and 6 repetitions per day to detect the preservative content in a certain brand of cosmetic emulsion. The intra-day and inter-day reproducibility results are shown in Table 6. The RSD values of intra-day and day-to-day test results did not exceed 5.0%, indicating good intra-day and day-to-day reproducibility.

[0059] Table 6 Intra-day and inter-day reproducibility test results

[0060]

Embodiment 3

[0061] Example 3 sample recovery experiment

[0062] Accurately weigh 1.00g of the cosmetic to be tested and place it in a 10mL stoppered colorimetric tube, add methanol to dissolve, add 500μL of standard series b (Table 2) to each sample, then dilute to the mark with methanol, ultrasonic power 2kW, Extract for 15 minutes, centrifuge at 6000 r / min for 5 minutes, and filter with a 0.45 μm filter membrane to obtain the test solution. Draw 10.0 μ L of the test solution, and measure according to the chromatographic conditions of Example 1, the average recovery range is 80.18% ~ 114.59%, and the RSD value range is 0.69% ~ 4.18% ( n =6) (see Table 7). This result shows: the method of the present invention has better recovery rate.

[0063] The sample recovery test result of table 711 kinds of standards

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com