Non-noble metal-nitrogen-carbon oxygen reduction catalyst and preparation method thereof

A non-precious metal, catalyst technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as unfavorable catalyst industrialization, complex catalyst preparation methods, and difficult control of process conditions in the preparation process, and achieve excellent stability and methanol resistance. , Good ORR catalytic activity, favorable effect of diffusion transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0066] Synthesis of tripyrrole-[1,3,5]-triazine (TPT):

[0067] Add 6.78g (0.10mol) of pyrrole and 80mL of anhydrous tetrahydrofuran into a 250mL single-necked round-bottomed flask, add KOH (8.86g, 0.15mol) into the above system under ice-cooling, rise to room temperature for 3 hours, and divide Add 5.59g (0.03mol) of cyanuric chloride in batches, and continue stirring at room temperature for 18h. After the reaction was completed, the reaction system was poured into a 250mL ice-water bath to settle, filtered, washed with deionized water three times (200mL×3), and then dried in a vacuum oven at 80°C for 24h. The obtained crude product was recrystallized with 15 mL of acetone and ethanol mixed solvent (acetone: ethanol ratio of 4:1), filtered, washed with ethanol, and the obtained off-white solid was vacuum-dried at room temperature to constant weight, 4.64 g, yield 56%, melting point: 210 ° C .

Embodiment 1

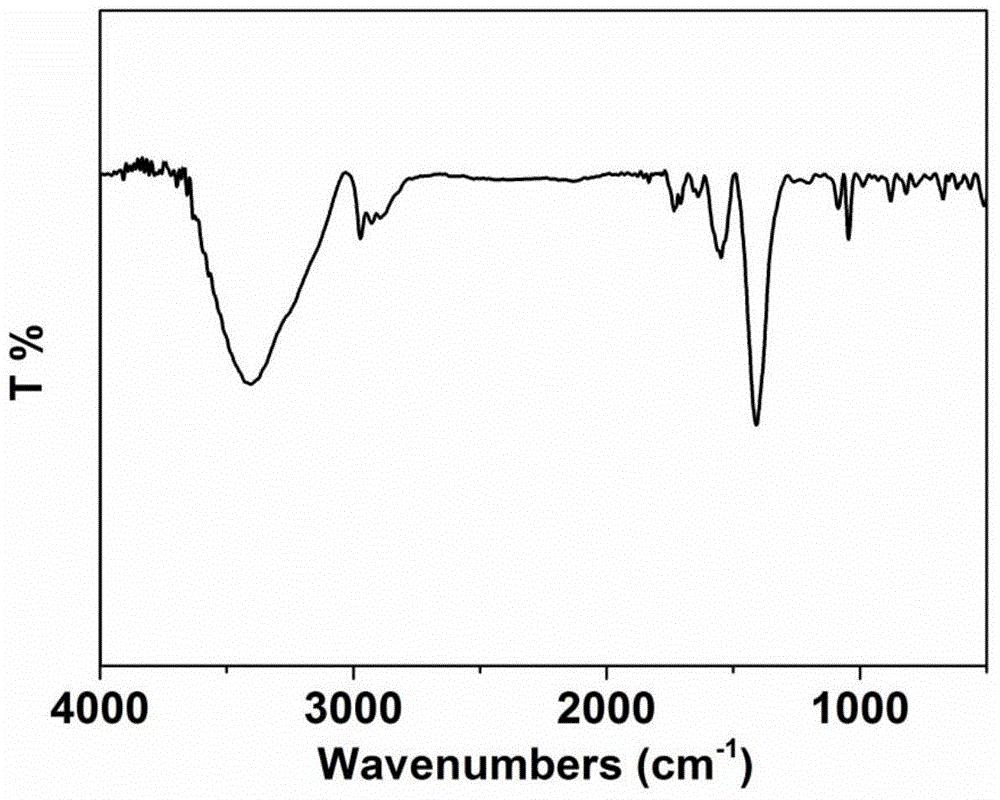

[0069] (1) Synthesis of P(TPT): Dissolve 110g (0.4mol) tripyrrole-[1,3,5]-triazine (TPT) in 2000mL nitrobenzene, then add 18.26g (0.24mol) dimethoxy Methyl methane and 32.28g (0.24mol) of anhydrous aluminum trichloride, stirred at 45°C for 5h, then raised to 80°C and stirred for 19h; after the reaction was completed, poured into 10L methanol for sedimentation, filtered, washed with water (1000mL×2), and dried Standby; The infrared spectrogram of polymer P (TPT) is shown as figure 1 shown;

[0070] The partial structure (i.e. repeating unit) of the polymer is as follows:

[0071] where n=1;

[0072] (2) Add 2.5g of P(TPT) and 0.7g of ferric nitrate (or ferric chloride) into 300mL of ethanol, ultrasonically disperse the whole system for 180min, evaporate the ethanol to dryness, and dry in a vacuum oven at 80°C 4h;

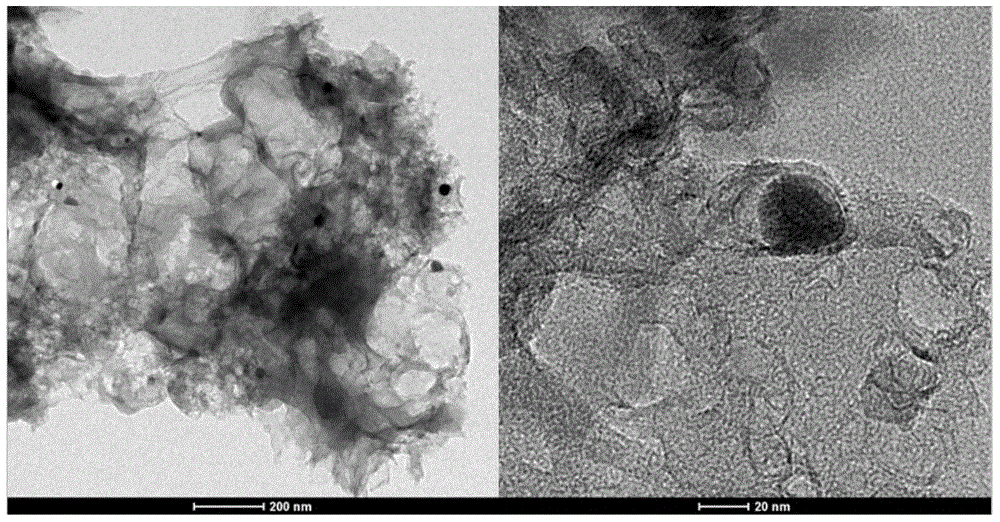

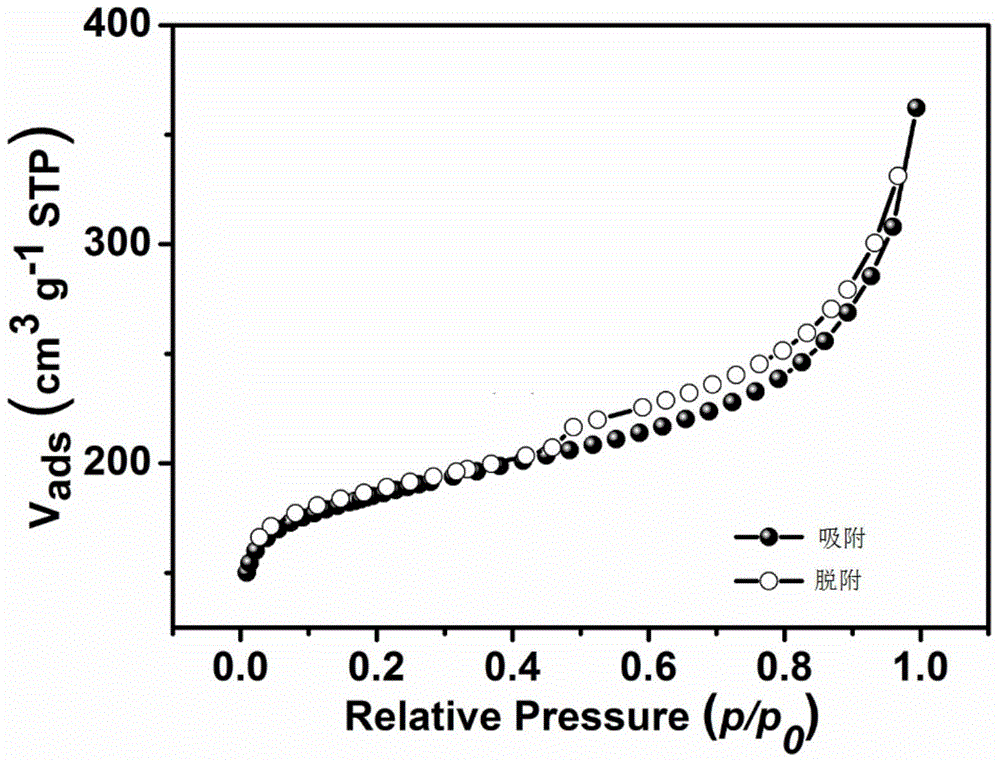

[0073] (3) Gained 3.2g powdery solid in N 2 Heat treatment at 800°C for 1 hour in the atmosphere to obtain 0.97g of nitrogen-doped carbon material;

[0074] ...

Embodiment 2

[0083] (1) Synthesis of P(TPT): Dissolve 110g (0.4mol) tripyrrole-[1,3,5]-triazine (TPT) in 2000mL nitrobenzene, then add 24g (0.24mol) dichloroethane and 32.28g (0.24mol) of anhydrous aluminum trichloride, stirred at 45°C for 5h, then raised to 80°C and stirred for 19h; after the reaction was completed, poured into 10L of methanol for settling, filtered, washed with water (1000mL×2), and dried for later use; The infrared spectrum of polymer P(TPT) is as follows figure 1 shown;

[0084] (2) Add 2.5g of P(TPT) and 0.7g of ferric chloride to 300mL of ethanol, ultrasonically disperse the whole system for 180min, then evaporate the ethanol to dryness, place it in a vacuum oven and dry at 80°C for 4h to obtain the primary mixture ;

[0085] (3) Gained 3.2g powdery solid in N 2 Heat treatment at 800°C for 1 hour in the atmosphere to obtain 0.98g of nitrogen-doped carbon material;

[0086] (4) The obtained nitrogen-doped carbon material was washed with 2000mL of 0.5M dilute sulfu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com