A kind of manufacture method of fluoroolefin

A manufacturing method and technology of fluoroolefins, applied in the field of fluoroolefins manufacturing, can solve the problems of saponification waste liquid recycling and treatment, saponification waste liquid recycling difficulties, product separation and purification difficulties, etc., to achieve convenient operation, avoid entrainment, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

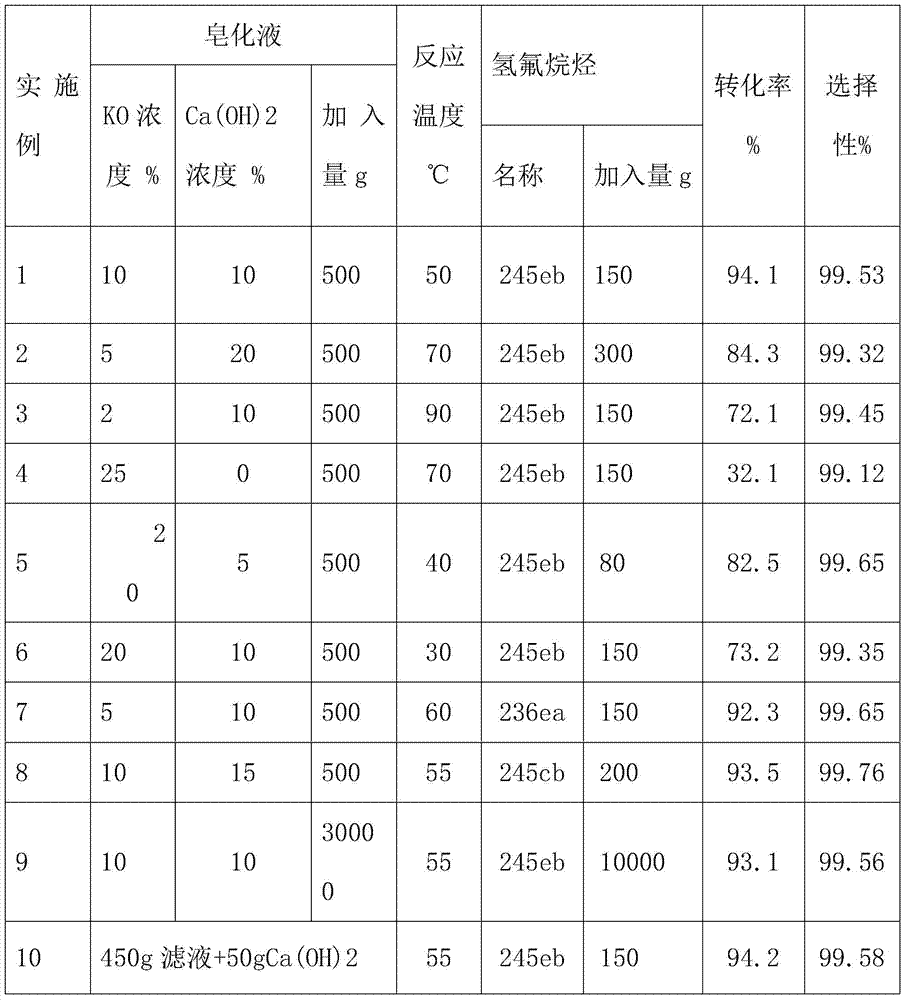

Examples

Embodiment 1

[0035] Add 500g of an aqueous solution containing 10% potassium hydroxide and 10% calcium hydroxide to a 1L reactor, heat it to 50°C under stirring, add 150g of HFC-245eb into the reactor, and react for 3h under stirring at 800rpm. Open the gas valve, collect the reaction gas in the air bag, analyze the collected reaction gas components, and calculate the conversion rate and selectivity.

Embodiment 2

[0037]Add 500g of an aqueous solution containing 5% potassium hydroxide and 20% calcium hydroxide to a 1L reactor, heat it to 70°C under stirring, add 300g of HFC-245eb into the reactor, and react for 3h under stirring at 800rpm, beat Open the gas valve, collect the reaction gas in the air bag, analyze the collected reaction gas components, and calculate the conversion rate and selectivity.

Embodiment 3

[0039] Add 500g of an aqueous solution containing 2% potassium hydroxide and 10% calcium hydroxide to a 1L reactor, heat it to 70°C under stirring, add 150g of HFC-245eb into the reactor, and react for 3h under stirring at 800rpm, beat Open the gas valve, collect the reaction gas in the air bag, analyze the collected reaction gas components, and calculate the conversion rate and selectivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com