Conductive cement-based composite material and its preparation method and application

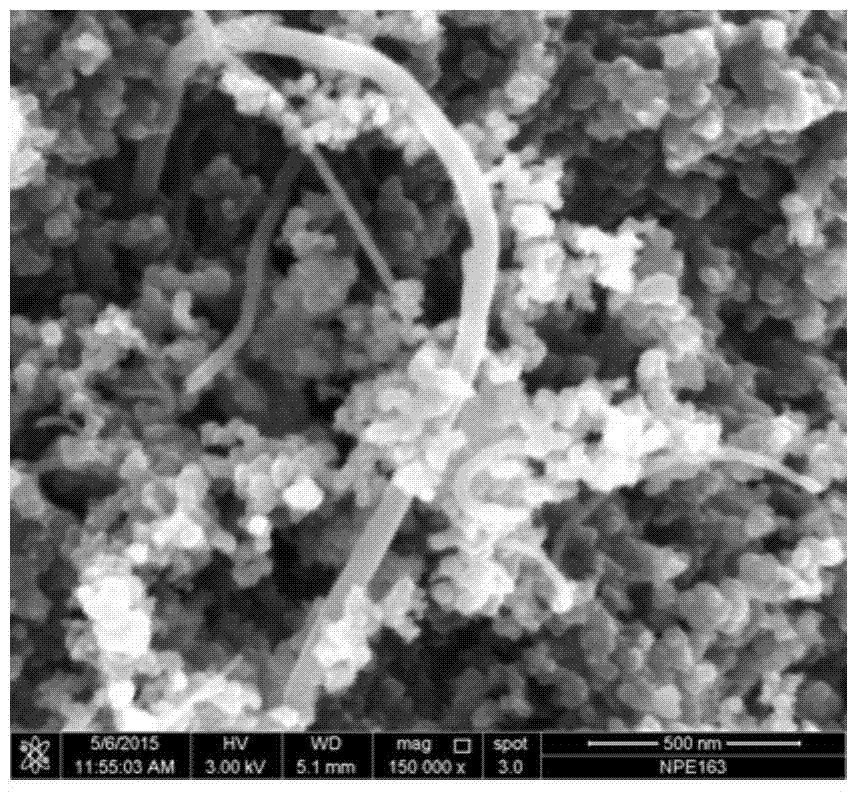

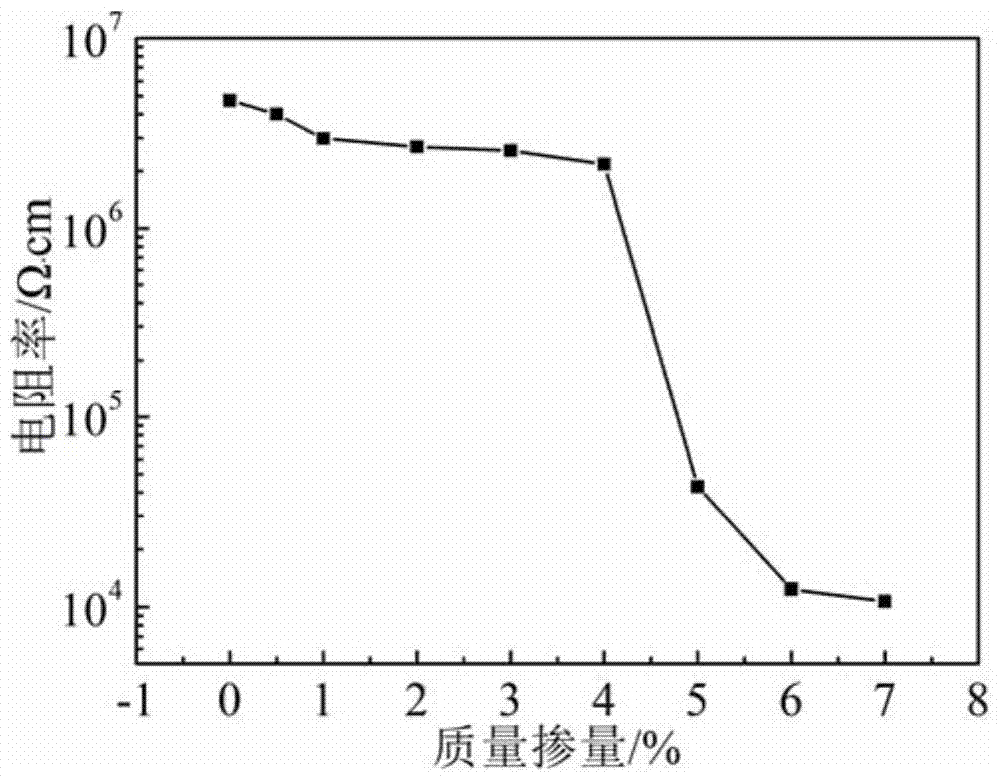

A composite material and conductive cement technology, applied in the field of building materials, can solve the problems of difficult dispersion of carbon nanotubes and nano-carbon black, and the weakening of large-volume nano-carbon black, and achieve good compactness, stable pressure sensitivity, and compatibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The only difference between the raw material and the comparative example is that 0.5 parts of electrostatic self-assembled carbon nanotubes / nanocarbon black are added.

[0058] The difference between the preparation method and the comparative example is that when the cement and fly ash are added, slowly add the electrostatic self-assembled carbon nanotubes / nanocarbon black while stirring slowly, and then stir quickly after adding, and the other steps are the same as the comparative example .

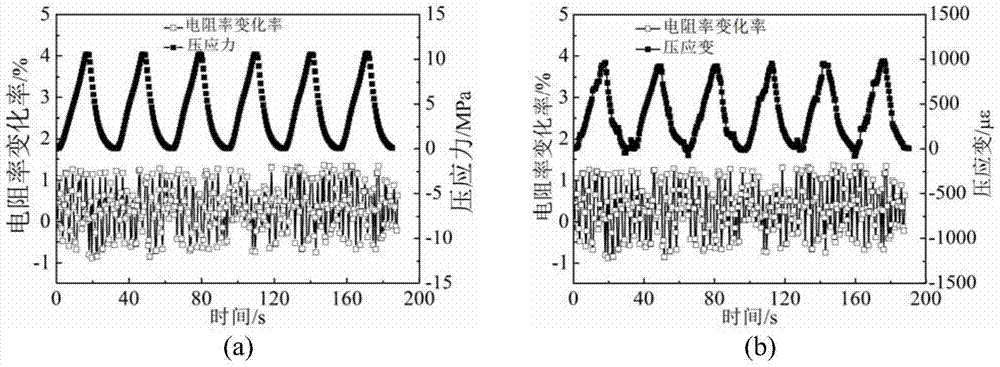

[0059] Static resistivity, resistivity change rate and sensitivity of table 4 embodiment 1 specimen

[0060]

Embodiment 2

[0062] The only difference between the raw material and Example 1 is that the amount of electrostatically self-assembled carbon nanotubes / nanocarbon black is 1 part.

[0063] The preparation method is the same as in Example 1.

[0064] Static resistivity, resistivity change rate and sensitivity of table 5 embodiment 2 test pieces

[0065]

Embodiment 3

[0067] The only difference between the raw material and Example 1 is that the amount of electrostatically self-assembled carbon nanotubes / nanocarbon black is 2 parts.

[0068] The preparation method is the same as in Example 1.

[0069] Static resistivity, resistivity change rate and sensitivity of table 6 embodiment 3 test pieces

[0070]

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com