Heat stress resisting premix for laying hen and preparation method of heat stress resisting premix

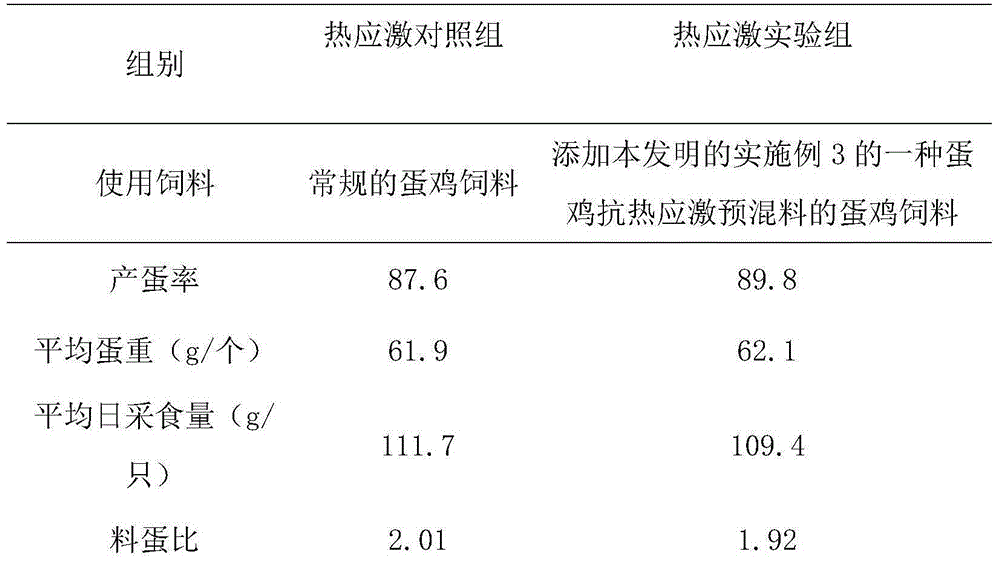

A technology of anti-heat stress and premix, which is applied in the field of laying hen feed, can solve the problems of lower production performance, lower appetite and feed intake, and lower egg production rate of laying hens, so as to improve feed intake and immunity , enhance the immune system, enhance the effect of heat stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An anti-heat stress premix for laying hens, consisting of the following components in parts by weight: glutamine 90, citric acid 5, fumaric acid 1, sodium acetate 2, sodium diacetate 2, sodium butyrate 4, Phenylacetic acid 1, bacitracin zinc 0.1, benzoic acid 6, yeast selenium 15, astaxanthin 2, γ-aminobutyric acid 8, oligosaccharide 100, three solid fermentation black tea dregs 650.

[0025] Among them, glutamine, citric acid, fumaric acid, sodium acetate, sodium diacetate, sodium butyrate, phenylacetic acid, bacitracin zinc, benzoic acid, yeast selenium, astaxanthin, γ-aminobutyric acid, oligosaccharides, It is a common commodity that can be purchased on the market, and its purity is feed grade.

[0026] Three solid fermented black tea dregs in embodiment 1 are prepared by the following processing technology:

[0027] (1) After mixing 65% black tea dregs with 15% rapeseed meal after autoclaving, 10% cottonseed meal and 10% bran, add fermentation strains, and ferment ...

Embodiment 2

[0033] An anti-heat stress premix for laying hens, consisting of the following components in parts by weight: glutamine 130, citric acid 10, fumaric acid 2, sodium acetate 3, sodium diacetate 3, sodium butyrate 5, Phenylacetic acid 2, bacitracin zinc 0.15, benzoic acid 8, yeast selenium 30, astaxanthin 4, γ-aminobutyric acid 12, oligosaccharide 150, third solid fermentation black tea dregs 800.

[0034] The sources of raw materials in Example 2 are the same as in Example 1, and the third solid fermented black tea dregs in this example are prepared by the preparation method provided in Example 1.

Embodiment 3

[0036]An anti-heat stress premix for laying hens, consisting of the following components in parts by weight: glutamine 130, citric acid 5, fumaric acid 1, sodium acetate 2, sodium diacetate 2, sodium butyrate g, benzene Acetate g, bacitracin zinc 0.13, benzoic acid 8, yeast selenium 30, astaxanthin 3, γ-aminobutyric acid 10, oligosaccharide 140, three solid fermentation black tea dregs 662.87.

[0037] The sources of raw materials in Example 3 are the same as in Example 1, and the third solid fermented black tea dregs in this example are prepared by the preparation method provided in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com