Peony and moringa soybean sauce and preparation method thereof

A technology of Moringa and Moringa, applied in the field of health-care soy sauce and its preparation, can solve the problems of not forming an industrial chain, lag in the development and utilization of deep-processed products of peony and Moringa, and low production added value, so as to improve immunity and increase the production of soy sauce. Variety, Great Benefit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

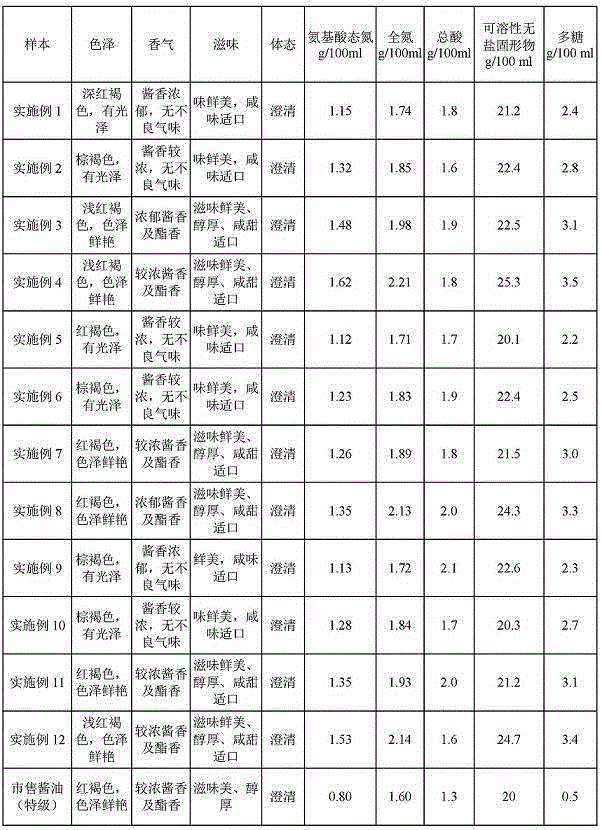

Examples

Embodiment 1

[0021] Step one, raw material processing.

[0022] Roast 20 parts of wheat at 320°C for 3 minutes, break it into 6~8 petals, crush 80 parts of peony seed cake into 2~3mm particles, add 40 parts of bran and stir evenly, then add 40% of the weight of the above mixture in water Moisturize for 8 hours.

[0023] Step two, cooking.

[0024] Cook for 20 minutes under the pressure of 0.1MPa, and the water content of the cooking material at this time is 40~60%.

[0025] Step three, making music.

[0026] Cool the cooked raw materials to 30~45°C, add 0.5% Aspergillus oryzae seed koji into the cooking material, mix well and transfer to the koji pond, adjust the temperature of the koji pond at 28~35°C, turn the koji to cool down when the temperature rises , After 25h, when the koji material turns from white to yellow-green, the koji is made.

[0027] Step 4, making unstrained spirits and fermenting.

[0028] Low-salt solid-state fermentation, crush the koji and transfer it to the fer...

Embodiment 2

[0032] Step one, raw material processing.

[0033] Roast 10 parts of wheat at 380°C for 1 min, break it into 6~8 petals, crush 100 parts of peony seed cake into 2~3mm particles, add 60 parts of bran and stir evenly, then add 60% of the weight of the above mixture in water Run the material for 0.5h.

[0034] Step two, cooking.

[0035] Cook under 0.2MPa pressure for 10 minutes, and the water content of the cooking material at this time is 40~60%.

[0036] Step three, making music.

[0037] Cool the cooked raw materials to 30~45°C, add 0.1% Aspergillus oryzae koji into the cooking material, mix well and transfer to the koji pond, adjust the temperature of the koji pond at 28~35°C, turn the koji to cool down when the temperature rises After 30 hours, when the koji material turns from white to yellow-green, the koji is made.

[0038] Step 4, making unstrained spirits and fermenting.

[0039] Low-salt solid-state fermentation, crush the koji and transfer it to the fermentation...

Embodiment 3

[0043] Step 1 to step 3, step 5 to step 6 are the same as in Example 1.

[0044] Step 4, making unstrained spirits and fermenting.

[0045] High-salt dilute state fermentation, the koji is crushed and transferred to the fermentation tank, and salt water at a temperature of 5-10°C and a concentration of 28g / 100ml is added at a mass ratio of 1:1.8 to prepare the soy mash. The fermentation period is 6 months, and the fermentation temperature in the early stage is 10~15℃, the fermentation time is 30d, inoculate 0.5% of the yeast in the raw material mass in the mid-term fermentation, the temperature is 20~25℃, the fermentation time is 90d, the late fermentation temperature is 30~35℃, the fermentation time is 60d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com