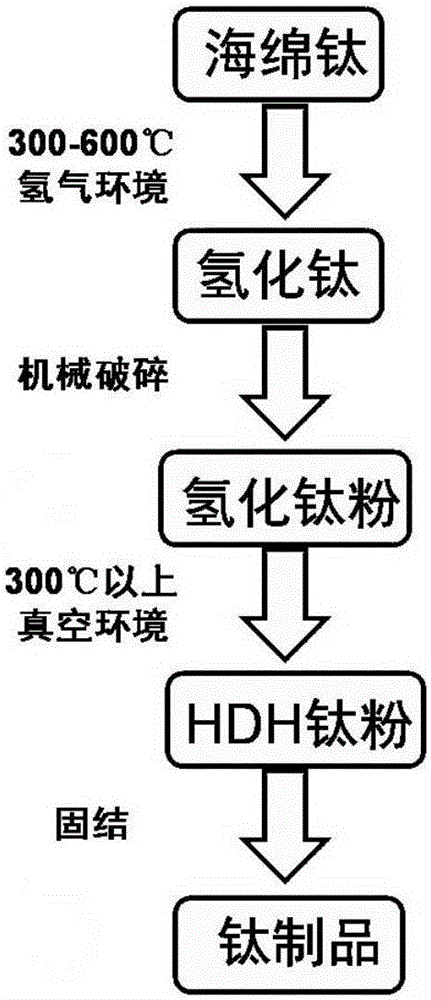

Method for preparing titanium product through titanium hydride powder

A technology of powder preparation and titanium hydride, which is applied in the field of preparing titanium products from titanium hydride powder and titanium products. It can solve the problems of high cost of HDH titanium powder, increased cost of parts, and low product density. It achieves low oxygen content, The effect of high density and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

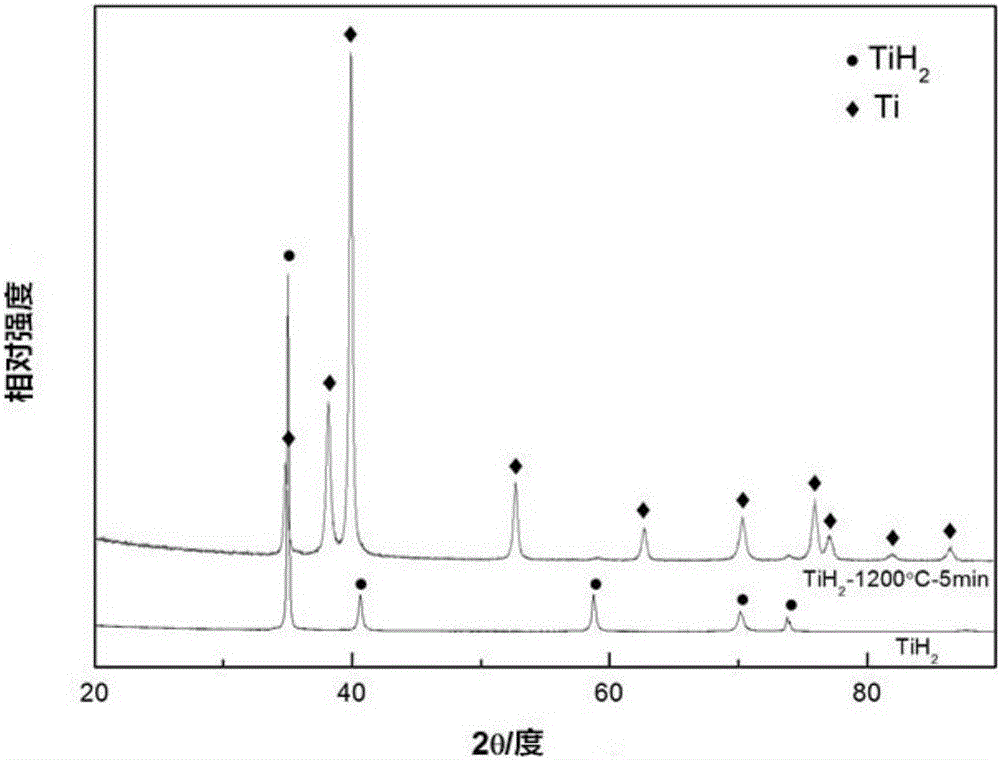

Examples

Embodiment 1

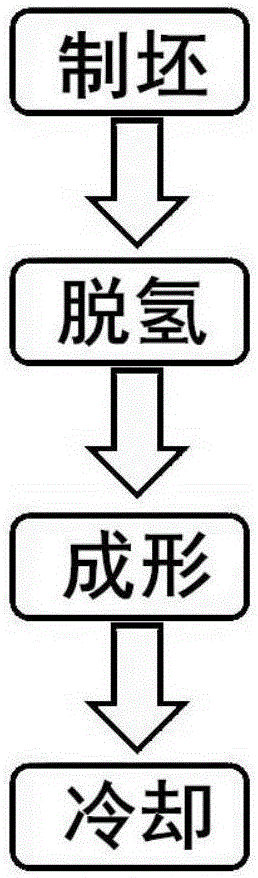

[0060] In this example, titanium hydride powder is used as a raw material, and the process and steps of preparing titanium products through rapid dehydrogenation, sintering and extrusion consolidation forming processes under the protection of argon are as follows:

[0061] 1. 50g of titanium hydride powder (-200 mesh) was pressed into a powder compact with a diameter of 28mm and a height of 20mm by one-way molding at room temperature under a pressure of 500MPa.

[0062] 2. In the self-modified induction heating and extrusion equipment, the induction coil and the extrusion device are placed in the same closed glove box. The titanium hydride powder compact is placed in the induction coil. Pass argon gas with a purity of 99.99% into the closed glove box, and use an oxygen analyzer to measure the oxygen content in the glove box until the atmospheric oxygen content in the glove box is lower than 100ppm. During the inflation process, the extrusion cylinder, the extrusion die and th...

Embodiment 2

[0066] 1. 50g of titanium hydride powder (-200 mesh) was pressed into a powder compact with a diameter of 28mm and a height of 19mm by unidirectional molding at 100°C under a pressure of 500MPa.

[0067] 2. In the self-modified induction heating and extrusion equipment, the induction coil and the extrusion device are placed in the same closed glove box. The titanium hydride powder compact is placed in the induction coil. Pass argon gas with a purity of 99.99% into the closed glove box, and use an oxygen analyzer to measure the oxygen content in the glove box until the atmospheric oxygen content in the glove box is lower than 100ppm. During the inflation process, the extrusion cylinder, the extrusion die and the extrusion rod are heated to 500° C. by means of electric heating coils.

[0068] 3. Adjust the power of the medium-frequency induction heating coil to heat the titanium hydride powder compact so that the heating rate is maintained at 100°C / min until the compact tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com