Method for loading nano-particles of metal or metallic oxide in mesoporous silica channel

A technology of mesoporous silica and nanoparticles, applied in the field of chemical modification, can solve the problems of poor product dispersibility, waste of precursors, uneven loading, etc., and achieve the effect of mild reaction conditions and uniform loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, preparation spherical mesoporous silica

[0031] Weigh 0.070g of cetyltrimethylammonium bromide and disperse it in 30ml of water, stir it magnetically at a constant temperature of 60°C until it becomes a clear, transparent and uniformly dispersed solution, and then add 1ml of it with a mass fraction of 28% to the solution concentrated ammonia water (adjust the pH value of the system to 11), add 1mL of tetraethoxysilane after 10min, react for 2h, then centrifuge, wash, and dry to obtain ellipsoidal mesoporous silica with a particle size of about 100nm. The rate is 98%. Then, it was calcined at 550° C. in air for 4 hours to remove the template surfactant hexadecyltrimethylammonium bromide in the pores.

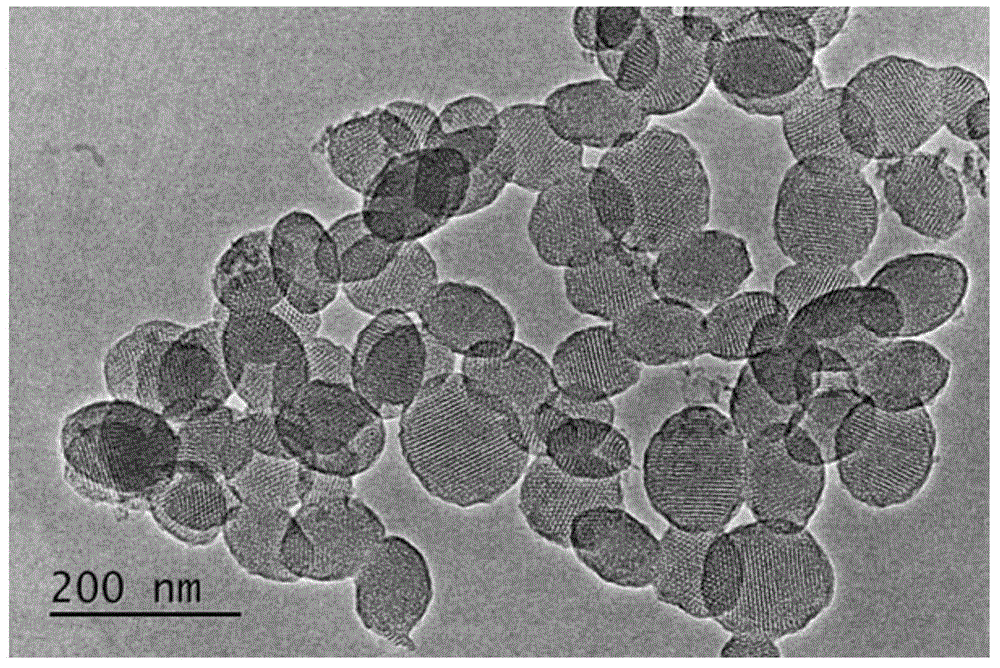

[0032] The spherical mesoporous silica transmission electron micrograph that this embodiment 1 prepares is as follows figure 1 shown. Depend on figure 1 It can be seen that the particle size of the silica ball is uniform, and the pore size is uniform.

Embodiment 2

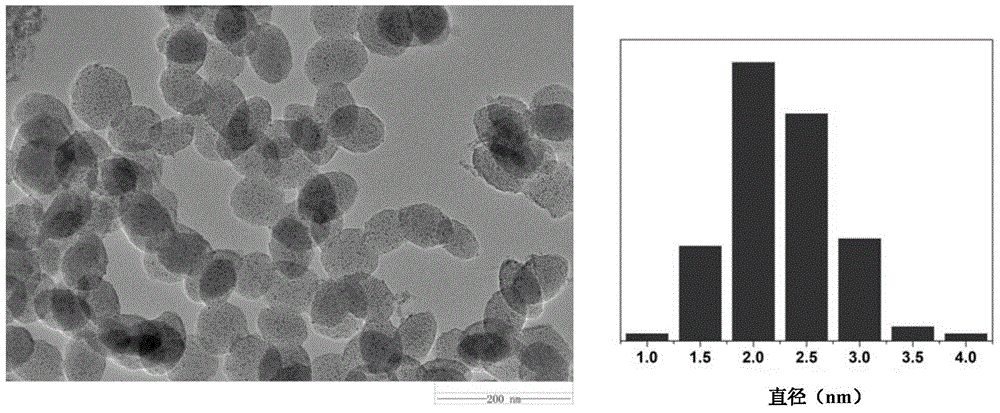

[0033] Example 2. Preparation of mesoporous silica-based composite material loaded with metal palladium nanoparticles in the channels of mesoporous silica

[0034] Add 0.07g of surfactant cetyltrimethylammonium bromide to 30ml of deionized water, stir at a constant temperature of 60°C until the solution becomes clear and transparent, then add 1ml of concentrated ammonia water with a mass fraction of 28% ( Adjust the pH of the system to 11), add 1mL of tetraethoxysilane (TEOS) after 10min, react at 60°C for 2h under constant temperature stirring, and then add the palladium source (the palladium source is specifically ammonium chloropalladate, Add 0.18mL (0.5mol / L) into the reaction system, continue the reaction at 60°C for 20h, then centrifuge, wash, and dry to obtain an ellipsoid with palladium nanoparticles loaded in the pores with a particle diameter of about 100nm. The mesoporous silica is then calcined in a hydrogen atmosphere at 700° C. for 2 hours to remove the template ...

Embodiment 3

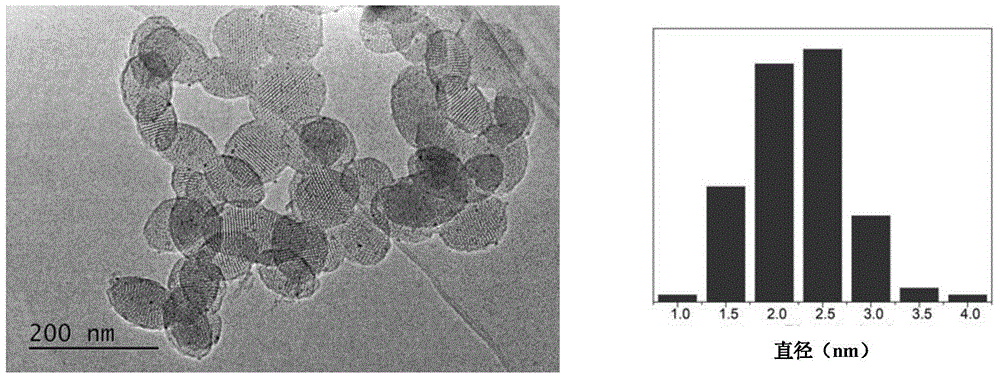

[0036] Example 3. Preparation of mesoporous silica-based composite material loaded with metal platinum nanoparticles in the channels of mesoporous silica

[0037]Add 0.070g of surfactant cetyltrimethylammonium bromide to 30ml of deionized water, stir at a constant temperature of 60°C until the solution becomes clear and transparent, then add 1ml of concentrated ammonia water with a mass fraction of 28% (Adjust the pH value of the system to 11), add tetraethoxysiloxane (TEOS) after 10 min to make the concentration within 1 mL, react at 60 ° C for 20 h under constant temperature stirring, and then add the platinum source (the described The platinum source is specifically chloroplatinic acid, the addition amount is 0.2mL (0.5M) into the reaction system, and the reaction is continued at 60°C for 4h, and then centrifuged, washed, and dried to obtain particles with a particle size of about 100nm. The ellipsoidal mesoporous silica of platinum nanoparticles is then calcined in a hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com