Industrial wastewater zero discharging technology for phytoextraction industry

A technology for production wastewater and plant extraction, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of scientific process structure design, strong condensation adsorption capacity and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

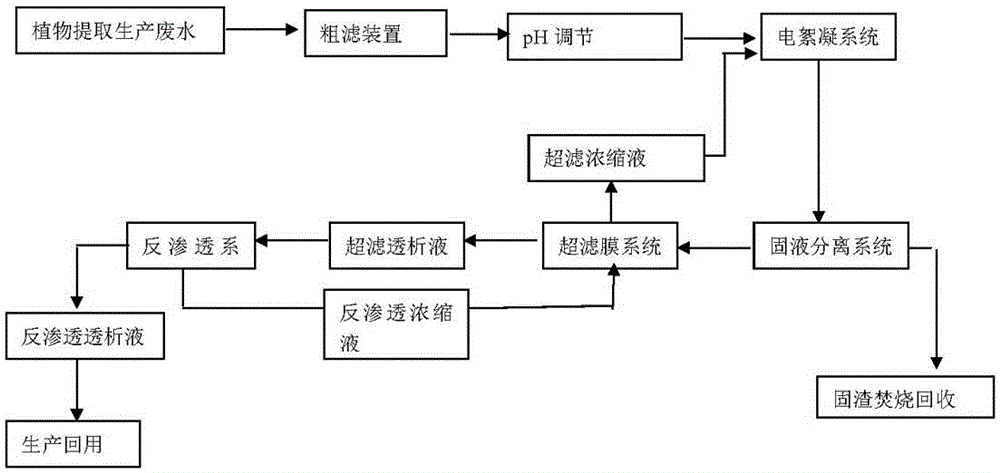

[0026] Such as figure 1 As mentioned above, the main process of the plant extraction industry production wastewater zero discharge process according to the present invention is: the production wastewater produced by plant extraction is first filtered through the grid, and then enters the electrocoagulation system through pH adjustment. The high-voltage pulse electrocoagulation technology adopts electric Based on chemical principles, with the help of external DC low current to generate high voltage, electrochemical reaction occurs, and electrical energy is converted into chemical energy. The organic or inorganic substances in wastewater can be oxidized and reduced by a single electrocoagulation device, and the formation is stable and easy to separate. At the same time, the equipment produces flocculation and sedimentation, air flotation and slag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com