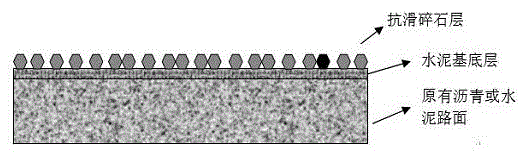

Cement-base colored microsurface and construction method thereof

A construction method and cement-based technology, which is applied to roads, on-site paved coagulation pavements, roads, etc., can solve the problem that the demulsification time of emulsified asphalt is greatly affected by construction conditions, the protection effect of the road surface cannot be maintained for a long time, and the asphalt Problems such as the influence of the mixture performance, to achieve the effect of material ratio, simple construction, easy operation, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The material composition of the cement base layer: 100 parts of cement, 150 parts of red quartz sand, 50 parts of water, 2.5 parts of water-based silicone resin, 0.1% of the volume of 3mm polyvinyl alcohol fiber, 7 parts of waterproofing agent, 9.2 parts of iron oxide red, Thioisatin 0.8 part.

[0042] Mortar preparation process:

[0043] ① Weigh 100 parts of cement, 9.2 parts of iron oxide red powder, and 0.8 parts of thioisatin powder, put them into a grinder and grind for about 1 hour, take them out, add 7 parts of waterproofing agent and mix well;

[0044] The waterproof agent model is ZL205, provided by Shenzhen Jinyuan Construction Technology Development Co., Ltd. The waterproof agent can effectively improve the impermeability and waterproof performance of cement mortar and improve its durability. It is a powder and can be mixed with cement to facilitate construction.

[0045] ②Use a graduated cylinder to measure 50 parts of water, weigh 2.5 parts of water-based ...

Embodiment 2

[0059] The material composition of the cement base layer: 100 parts of cement, 160 parts of red quartz sand, 50 parts of water, 10 parts of water-based epoxy resin, 13 parts of corresponding curing agent, 0.1% of 6mm polyvinyl alcohol fiber volume, 7 parts of waterproofing agent , 9.2 parts of iron oxide red, 0.8 parts of thioisatin.

[0060] Mortar preparation process:

[0061] ① Weigh 100 parts of cement, 9.2 parts of iron oxide red powder, and 0.8 parts of thioisatin powder, put them into a grinder and grind for about 1 hour, take them out, add 7 parts of waterproofing agent and mix well;

[0062] The waterproof agent model is ZL205, provided by Shenzhen Jinyuan Construction Technology Development Co., Ltd. The waterproof agent can effectively improve the impermeability and waterproof performance of cement mortar and improve its durability. It is a powder and can be mixed with cement to facilitate construction.

[0063] ②Use a measuring cylinder to measure 50 parts of wate...

Embodiment 3

[0076] The material composition of the cement base layer: 100 parts of cement, 170 parts of red quartz sand, 50 parts of water, 3 parts of hydroxycellulose, 0.1% of 3mm polyvinyl alcohol fiber volume content, 7 parts of waterproofing agent, 9.2 parts of iron oxide red, sulfur Indigo 0.8 parts.

[0077] Mortar preparation process:

[0078] ① Weigh 100 parts of cement, 9.2 parts of iron oxide red powder, and 0.8 parts of thioisatin powder, put them into a grinder and grind for about 1 hour, take them out, add 7 parts of waterproofing agent and mix well;

[0079] The waterproof agent model is ZL205, provided by Shenzhen Jinyuan Construction Technology Development Co., Ltd. The waterproof agent can effectively improve the impermeability and waterproof performance of cement mortar and improve its durability. It is a powder and can be mixed with cement to facilitate construction.

[0080]②Use a graduated cylinder to measure 50 parts of water, weigh 3 parts of hydroxycellulose, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com