Magnetic conductive type organosilicone pouring sealant and preparation method thereof

A silicone potting, magnetic permeability technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of electromagnetic radiation cannot be effectively shielded in places without magnetic permeability and electromagnetic waves, etc. Achieve the effect of improving magnetic permeability, shielding electromagnetic radiation, and improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

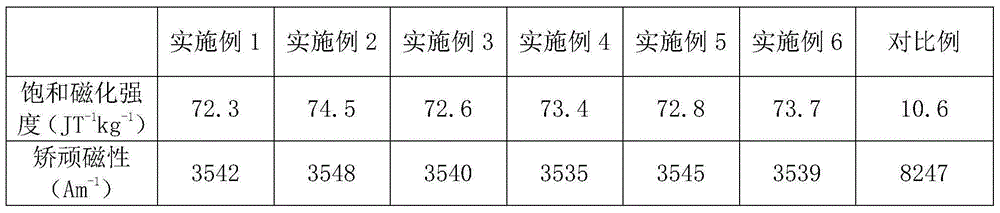

Examples

Embodiment 1

[0029] A magnetically conductive silicone potting compound, made of component A and component B with a mass ratio of 1:1, component A is composed of the following components by weight: 100 parts of vinyl silicone oil, nano-zinc ferrite 17 parts, 9 parts of silicon dioxide, 4.5 parts of aluminum hydroxide, 15 parts of A1511, 0.7 parts of methyl butynol, 4 parts of allyl glycidyl ether, 7.5 parts of PPS, 2.5 parts of hydrogen silicone oil, 2.4 parts of carbon black ; Component B consists of the following components by weight: 100 parts of vinyl silicone oil, 1.8 parts of chloroplatinic acid.

[0030] The steps of its preparation method are as follows:

[0031] (1) Add nano-zinc ferrite into the acetic acid solution with a mass fraction of 12%, stir and disperse at room temperature for 40 minutes, add A151 with a mass of 1.5% nano-zinc ferrite, heat up to 90°C and stir for 20 hours, stop stirring and keep warm After 1 hour, filter the reacted solution, wash the filter cake with ...

Embodiment 2

[0036] A magnetically conductive silicone potting compound, made of component A and component B with a mass ratio of 1:1, component A is composed of the following components by weight: 100 parts of vinyl silicone oil, nano-zinc ferrite 19 parts, fumed silica 9.5 parts, aluminum hydroxide 4.4 parts, A1511.4 parts, methyl butynol 0.8 parts, allyl glycidyl ether 3.5 parts, PPS 7.7 parts, hydrogen silicone oil 2 parts, 2.5 parts of carbon black; component B consists of the following components by weight: 100 parts of vinyl silicone oil, 2 parts of chloroplatinic acid.

[0037] The steps of its preparation method are as follows:

[0038] (1) Add nano-zinc ferrite into the acetic acid solution with a mass fraction of 12%, stir and disperse at room temperature for 40 minutes, add A151 with a mass of 1.5% nano-zinc ferrite, heat up to 90°C and stir for 20 hours, stop stirring and keep warm After 1 hour, filter the reacted solution, wash the filter cake with deionized water and aceton...

Embodiment 3

[0043]A magnetically conductive silicone potting compound, made of component A and component B with a mass ratio of 1:1, component A is composed of the following components by weight: 100 parts of vinyl silicone oil, nano-zinc ferrite 20 parts, 10 parts of silicon dioxide, 5 parts of aluminum hydroxide, 1.5 parts of A151, 0.6 parts of methyl butynol, 3 parts of allyl glycidyl ether, 7.6 parts of PPS, 4.5 parts of hydrogen silicone oil, carbon black 2 parts; component B consists of the following components by weight: 100 parts of vinyl silicone oil, 1.6 parts of chloroplatinic acid.

[0044] The steps of its preparation method are as follows:

[0045] (1) Add nano-zinc ferrite into the acetic acid solution with a mass fraction of 12%, stir and disperse at room temperature for 40 minutes, add A151 with a mass of 1.5% nano-zinc ferrite, heat up to 90°C and stir for 20 hours, stop stirring and keep warm After 1 hour, filter the reacted solution, wash the filter cake with deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com