Preparation method suitable for industrialized continuous production of enzyme modified soybean phospholipids

A technology for modifying and concentrating phospholipids, applied in the field of bioengineering, to achieve the effects of strong emulsifying performance, improved production efficiency and fewer operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

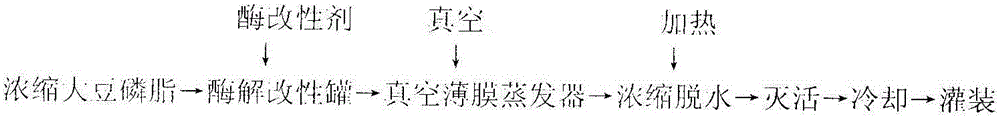

Method used

Image

Examples

Embodiment 1

[0029] 1000kg of concentrated soybean lecithin with an acid value of 19.5KOHmg / g is pumped into the lecithin stirring tank by a delivery pump, heated to make the temperature of soybean lecithin in the lecithin tank reach 70°C, and slowly add 5.0kg of soybean lecithin under stirring condition of 350rpm / min Phospholipase A1 (enzyme activity 1000IU / 100g) and 50 kg of distilled water were used for enzymatic hydrolysis for 28 hours to make the acid value of soybean lecithin 64.0KOHmg / g. Then the screw pump is pumped into a fixed scraper film evaporator with a temperature of 160°C, an absolute pressure of 3.0KPa, and a rotation speed of 300rpm for evaporating and dehydrating for 3 minutes, so that the moisture content of soybean phospholipids is below 0.67%, and then pumped into a phospholipid cooler by a screw pump for cooling When it reaches 58°C, put it into a vacuum stirring tank to deoxygenate the modified phospholipids, then weigh and pack.

Embodiment 2

[0031] 800kg of concentrated peanut phospholipids with an acid value of 21.6KOHmg / g is pumped into the phospholipid stirring tank by the delivery pump, heated to make the temperature of the peanut phospholipid in the phospholipid stirring tank reach 55°C, and slowly add 6kg of peanut phospholipids under stirring conditions of 450rpm / min Phospholipase A1 (enzyme activity 6000IU / 100g) and 80 kilograms of distilled water were used for enzymatic hydrolysis for 16 hours to make the acid value of peanut phospholipid 55.0KOHmg / g. Then the screw pump is pumped into the fixed scraper film evaporator with a temperature of 150°C, an absolute pressure of 5.0KPa, and a rotation speed of 400rpm for evaporating and dehydrating for 3 minutes, so that the water content of the concentrated peanut phospholipids is below 0.81%, and then pumped into the phospholipid cooler by the screw pump Cool down to 62°C and put into a vacuum stirring tank to deoxygenate the modified phospholipids, then weigh a...

Embodiment 3

[0033] 2000kg of concentrated soybean lecithin with an acid value of 22.5KOHmg / g is pumped into the phospholipid stirring tank by the delivery pump, heated to make the temperature of the soybean lecithin in the phospholipid stirring tank reach 60°C, and slowly add 55kg The phospholipase A1 and phospholipase A2 mixed solution (enzyme activity 2000IU / 100g) and 160 kilograms of distilled water, enzyme hydrolysis 18h makes the acid value of soybean lecithin 58.2KOHmg / g. Then the screw pump is pumped into the fixed scraper film evaporator with a temperature of 130°C, an absolute pressure of 2.0KPa, and a rotation speed of 300rpm for evaporating and dehydrating for 3.5 minutes, so that the moisture content of soybean phospholipids is below 0.42%, and then pumped into the phospholipid cooler by a screw pump After cooling down to 60°C, put it into a vacuum stirring tank to deoxygenate the modified phospholipids, then weigh and pack.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com